|

|

August 27th, 2023

For today’s Sunday GunDay story, we feature highlights from two in-depth reports on rifles built around the relatively new 6GT cartridge (also known as the “6mm GT”). Developed by George Gardner (G.A. Precision) and Tom Jacobs (Vapor Trail), the 6GT was designed to feed well from magazines, be more efficient than the 6mm Creedmoor, and offer outstanding accuracy. It is just enough bigger than the 6mmBR or 6 Dasher so it feeds better. But it retains many of the qualities of the 6mmBR (high efficiency and outstanding accuracy). Burning significantly less powder than the 6mm Creedmoor, the 6GT is a bit less expensive to shoot, and should, theoretically at least, deliver better barrel life.

“The [6GT] is a more predictable and barrel-friendly cartridge than the 6mm Creedmoor. It can utilize the accurate and forgiving powders of the 6BR, has fantastic accuracy, and due to its shoulder angle and case length, it doesn’t suffer from feeding issues.” — PewPewTactical.com

We should say that the 6 Dasher has been used very successfully in PRS/NRL competition, with some aftermarket magazine accessories. For this reason, if you already shoot a 6 Dasher, moving to a 6GT may not be worth the cost of new dies and new brass. A.J. Deysel, writing for LoadDevelopment.com, writes:

“The longer case of the 6mm GT means it feeds as reliably from a magazine as a 6mm Creedmoor, and offers slightly higher powder capacity and in turn velocities than the 6mmBR variants, whilst still being able to use the same accurate and forgiving propellants.

You will also find many competitive and average Joes shooting 6mmBR and 6mm Dashers with a Primal Rights or some other mag conversion kit, having very few if any mag-feed issues at all, so that pretty much also nullifies the need to move away from those [chamberings] if you already own one of those or the reloading equipment for it.” — LoadDevelopment.com

Part I: The 6GT Cartridge for Precision Rifle Competition

Report by Vu Pham

I was ready to build a 6 Dasher when I saw a lot of buzz… about a new caliber George Gardner (Owner of G.A. Precision) and Tom Jacobs (Owner of Vapor Trail Bullets) designed, the 6GT. After some research and talking to George, I ditched the 6mm Dasher build and had GA Precision build me a 6GT on a GAP Templar action I already had in the safe. The reasons to try the 6GT in a new PRS-style rig were as follows:

1. Push a 110-115 grain class bullet at 2880-2930 FPS safely in the Sacramento heat.

2. Achieve a load that is reliable and predictable. The caliber must be easy-to-tune and predictable from barrel to barrel. I don’t want to spend weeks developing a new load each time I spin on a fresh barrel.

3. Be able to run the same mag in all my guns without having to tweak or use mag kits. The round must feed from AICS and AW magazines without major tweaking or hiccups.

4. Get good barrel life. The barrel needs to go 2200-2500 rounds with match-grade reliability and accuracy.

5. Have a competitive cartridge with the least possible recoil without sacrificing too much performance down range, compared to bigger options like the 6mm Creedmoor.

6GT feeding from un-modified magazines has been flawless in all the rifles we tested. The 6GT feeds so well, I sometimes have to do a press check to ensure there is a round in the chamber.

On paper the 6GT seemed like the perfect cartridge for PRS- and NRL-style competition. It has the low recoil of a 6 Dasher, with good feeding and mag compatibility. With the 6GT, a competitor can push 105gr bullets at 3000+ FPS or run heavier bullets at 2800-2900+ FPS.

Knowing that I would initially have to make my own 6GT brass and do quite a bit of load development, I enlisted the help of Dan Bertocchini with CS Tactical. Dan has a lot more experience with wildcats and is the man when it comes to this type of data gathering. He has been running a 6 Dasher for a few years so I was curious how he would compare the 6GT to his 6 Dasher.

Quick Summary: “I am really digging the 6GT and the capabilities it offers. It can launch 103gr Vapor Trails at 3000+ FPS or lob heavy 115gr DTACs in the low-to-mid 2900s comfortably. I think we will see this cartridge go mainstream in PRS/NRL-style competition in 2020.” — Vu Pham

| The new 6GT Cartridge Was Tested in Three (3) Tactical Rifles: |

|

Rifle 1: Vu’s 6GT 1.0

Builder: GA Precision

Action: Left Hand GAP Templar (large firing pin)

Barrel: Bartlein 7.7 Twist finished at 26″ with a 419 Hellfire Brake

Stock: KMW Sentinel

Optic: Vortex Razor Gen II 4.5-27x56mm EBR-7C MRAD

Bi-Pod: Harris

Trigger: Timney Calvin Elite

Magazines: AICS and AW

Support Bag: Wiebad Fortune Cookie |

Rifle 2: Vu’s 6GT 2.0

Builder: Rubicon Precision

Action: Impact Precision 737

Barrel: Bartlein 7.0 Twist finished at 27″ with a 419 Hellfire Brake

Stock: XLR Industries Envy Chassis

Optic: Vortex Razor Gen II 4.5-27x56mm EBR-7C MRAD

Bi-Pod: Harris with Henderson Arca adapter

Trigger: Trigger Tech Diamond

Magazines: AICS and AW

Support Bag: Wiebad Fortune Cookie |

Rifle 3: Dan’s 6GT

Builder: CS Tactical

Chambered by: Rubicon Precision

Action: Lone Peak Arms Fusion

Barrel: Proof 7.0 Twist finished at 28″ with a Muzzle Brake and More Brake

Stock: XLR Industries Envy Chassis

Optic: Minox ZP5 5-25x56mm MR4

Bi-Pod: Arca Cyke Pod (PRS)

Trigger: Trigger Tech Diamond

Magazines: MDT

Support Bag: Armageddon Gear OG Game Changer, Waxed Canvas |

Alpha Munitions Pre-Production 6GT Brass

George Gardner was kind enough to send us 50 pieces of Pre-Production Alpha 6GT brass for preliminary testing. Like the cases I formed from 6.5×47 Lapua brass, the Alpha 6GT brass will use a small rifle primer. Purchased direct from Alpha Munitions, 6GT brass is now $1.30 per case, which is comparable with Lapua 6mm Creedmoor brass, currently $120.99/100 at Grafs.com. George Gardner was kind enough to send us 50 pieces of Pre-Production Alpha 6GT brass for preliminary testing. Like the cases I formed from 6.5×47 Lapua brass, the Alpha 6GT brass will use a small rifle primer. Purchased direct from Alpha Munitions, 6GT brass is now $1.30 per case, which is comparable with Lapua 6mm Creedmoor brass, currently $120.99/100 at Grafs.com.

The major difference between 6.5×47 Lapua-formed brass and Alpha 6GT brass is the case capacity. Alpha 6GT brass has 1.5 to 1.7 grains more case capacity. When a piece of 6.5×47 Lapua brass is formed into a 6GT, the walls of the case now become the shoulder and part of the neck. In a normal piece of brass, the shoulder and neck are typically thinner because of the thickness of the brass tapering from the body to neck.

While the cartridge design was optimized for Hodgdon Varget, the extra case capacity of the Alpha 6GT brass opens the door to Hodgdon H4350 (my favorite powder) and Alliant Reloder 16.

Test Results with Alpha Munitions 6GT Brass

Initial test results were as expected from a premium brass-maker. Dan and I both got excellent Standard Deviations and Extreme Spreads over my MagnetoSpeed V3 and his LabRadar. This string below was with 112gr Barnes Match Burners and 33.8 grains of Varget. Can’t complain about a 3 FPS Extreme Spread!

Yes, H4350 Works with the Alpha Munitions Brass

Personally, I prefer running Alpha 6GT brass with H4350 rather than Varget pushing a heavier bullet. H4350 burns slower and cleaner which should equate to better barrel life. The Lapua-formed 6GT cases just do not have the capacity to reach the cartridge’s full capability with the slower burning powders.

Is the 6GT cartridge accurate? Definitely. Here is a 5-shot group at 600 yards shot by Dan. This was Alpha 6GT brass, with Hodgdon H4350 pushing Barnes 112gr Match Burner bullets.

PART II — 6GT Load Development with Multiple Powders

This text is taken from a full report by Mike McCasland on his 6GT (aka “6mm GT”) bolt action rifle. This rig was designed for general use, not just for PRS/NRL matches. In his 6GT rifle, Mike tested multiple powders including Varget, H4350, Reloder 16, Reloder 15, Shooters World Precision, and Vihtavuori N140. For more details, CLICK HERE for full report.

About the 6mm GT Cartridge

BRASS — The first thing you’ll find is cartridge brass choices for the 6 GT are rather limited currently. At present, the only commercial options are Hornady and Alpha Munitions. For the die-hard Lapua fans, you can technically make 6mm GT brass from 6.5×47 Lapua, however that process is very labor-intensive. BRASS — The first thing you’ll find is cartridge brass choices for the 6 GT are rather limited currently. At present, the only commercial options are Hornady and Alpha Munitions. For the die-hard Lapua fans, you can technically make 6mm GT brass from 6.5×47 Lapua, however that process is very labor-intensive.

I have used both Hornady and Alpha brass in this rifle and haven’t noticed much difference between the two. I will say that my batch of Alpha brass was slightly softer than Alpha brass I’ve used in other calibers; you could feel a difference when neck turning cases. I’m unsure if that’s a batch issue, or something specific to their 6mm GT brass as a whole. As far as performance, there was little discernable difference. Oddly enough, the Hornady brass seemed to have slightly less case capacity than the Alpha; with most other cartridges it’s the other way around.

POWDERS — The 6mm GT was designed with Hodgdon Varget in mind, and that popular powder works exceedingly well in this platform. That said, the 6mm GT can work with a wide variety of powders, some yielding better performance than Varget.

I’ve tried a multitude of powders during my initial 6mm GT load development: Varget, Shooters World Precision, RL16, VV N140, H4350, and RL-15 to name a few. In my barrel, Hodgdon H4350 seems to deliver the best velocity/accuracy combination. SD and ES also seemed to be the lowest with H4350.

Load Development for the 6mm GT — Many Powders Tested

BULLETS — The most common 0.120″ freebore chamber allows for the majority of high-BC 6mm projectiles found in both F-Class and PRS. I had good luck with the pointed 107gr Sierra Match Kings (SMK), as well as the 110gr Hornady A-Tips in my rifle. For those looking to run the heavier 112-115 grain 6mm offerings, I believe GAP designed a 0.160″ freebore reamer that gets those bullets out of the neck/shoulder junction. Shown below is the 0.120″ freebore JGS reamer print:

SUMMARY — Good Cartridge with Much Potential SUMMARY — Good Cartridge with Much Potential

Generally speaking, I think the 6mm GT is a good little round. Some may not subscribe to this theory, but I believe some cartridges are inherently easier to tune than others. I’m not sure the 6mm GT is as easy-to-tune as a 6mmBR, 6 Dasher, or 6 BRA, but I don’t think it lags that far behind.

With relatively little trouble, I was able to find loads with both Varget and H4350 that would consistently shoot very well — 0.2 to 0.3 MOA. Moreover, I found the 6GT cartridge lives up to the velocity claims made by G.A. Precision. I was easily able to push the 110gr A-Tips to 2950 FPS, and the 107gr SMKs to low 3000 FPS range without any pressure signs, or unnecessary wear and tear on the brass.

As a fun test, I ran my 6mm GT rifle in a local 1000-yard F-Class match with the 110gr A-Tips, just to see just how well they would perform. Although wind conditions of the day and some E-Target issues prevented my 6mm GT rig from getting the better of the larger 7mm and .30-Cal rifles, the 6mm GT proved itself an accurate little round at distance. Here is a 1000-yard ShotMarker target:

After putting several hundred rounds through my 6mm GT rifle, I anticipate building another 6GT on a repeater action to give PRS a try. I think if you are looking for a dual-purpose rifle that can run tactical matches (with 100% feeding reliability), and can also be used for mid-range, F-Open Class competition, the 6mm GT would be a very good option.

About the author, Mike McCasland:

Mike McCasland is an avid shooter who competes regularly in F-Class matches. Based in Texas, Mike is the creator of the Texas Precision YouTube Channel. There you’ll find many videos covering reloading, gun projects, and marksmanship. Mike has done some notable product reviews including a comparison test of Micrometer Competition Seating Dies. To access Mike’s YouTube Channel, CLICK HERE.

Share the post "Sunday GunDay: 6GT Cartridge for PRS/NRL Competition"

August 26th, 2023

Put the same load in a variety of barrels (with the same length and chamberings) and you’ll see a wide variance in muzzle velocity. In fact, it’s not unusual to see up to 100 fps difference from one barrel to the next. We demonstrated this with a comparison test of Lapua factory ammo.

Chron Testing Lapua Factory Ammo

At our Southern California test range some years ago, we chronographed Lapua 105gr 6mmBR factory ammo in three different 8-twist barrels of similar length. The results were fascinating. Lapua specs this ammo at 2790 fps, based on Lapua’s testing with its own 26″ test barrel. We observed a speed variance of 67 fps based on tests with three aftermarket barrels.

Barrel Velocity Variance Barrel Velocity Variance

Brand ‘S’ and Brand ‘PN’ were pre-fit barrels shot on Savage actions. Brand ‘K’ was fitted to a custom action. All test barrels were throated for the 100-108 grain bullets, though there may have been some slight variances in barrel freebore. With a COAL of 2.330″, the rounds were “jumping” to the rifling in all barrels.

Among the four barrels, Brand ‘PN’ was the fastest at 2824 fps average — 67 fps faster than the slowest barrel. Roughly 10 fps can be attributed to the slightly longer length (27″ vs. 26″), but otherwise this particular barrel was simply faster than the rest. (Click Here for results of 6mmBR Barrel Length Velocity Test).

IMPORTANT: Results Are Barrel-Specific, Not Brand-Specific

These tests demonstrate that the exact same load can perform very differently in different barrels. We aren’t publishing the barrel-makers’ names, because it would be wrong to assume that ‘Brand X’ is always going to be faster than ‘Brand Y’ based on test results from a single barrel. In fact, velocities can vary up to 100 fps with two identical-spec barrels from the SAME manufacturer. That’s right, you can have two 8-twist, 26″ barrels, with the same land-groove configuration and contour, from the same manufacturer, and one can be much faster than another.

Don’t Demand More Than Your Barrel Can Deliver

We often hear guys lament, “I don’t get it… how can you guys get 2900 fps with your 6BRs and I can only get 2840?” The answer may simply be that the barrel is slower than average. If you have a slow barrel, you can try using more powder, but there is a good chance it may never run as fast as an inherently fast barrel. You shouldn’t knock yourself out (and over-stress your brass) trying to duplicate the velocities someone else may be getting. You need to work within the limits of your barrel.

Factory Ammo Provides a Benchmark

If you have a .223 Rem, 6mmBR, .243 Win, 6.5×47 Lapua, 6.5 Creedmoor, 6.5×55, .308 Win, .30-06 Springfield, or .338 LM Rifle, we recommend you buy a box of Lapua factory-loaded ammo. This stuff will shoot great (typically around half-MOA), and it can give you a baseline to determine how your barrel stacks up speedwise. [Editor’s NOTE: The original test was conducted in 2008. The velocity of current-production Lapua factory ammo might be higher or lower, so your results may vary.]

When you complete a new 6mmBR rifle, it’s definitely smart to get a box of the factory ammo and chronograph it. That will immediately give you a good idea whether you have a slow, average, or fast barrel. Then you can set your velocity goals accordingly. For example, if the factory 6BR ammo runs about 2780-2790 fps in your gun, it has an average barrel. If it runs 2820+ in a 26″ barrel (or 2835 fps in a 28″), you’ve got a fast tube.

Share the post "Same 6BR Lapua Ammo in 4 Barrels — Surprising Velocity Results"

October 2nd, 2022

Put the same load in a variety of barrels (with the same length and chamberings) and you’ll see a wide variance in muzzle velocity. In fact, it’s not unusual to see up to 100 fps difference from one barrel to the next. We demonstrated this with a comparison test of Lapua factory ammo.

Chron Testing Lapua Factory Ammo

At our Southern California test range some years ago, we chronographed Lapua 105gr 6mmBR factory ammo in three different 8-twist barrels of similar length. The results were fascinating. Lapua specs this ammo at 2790 fps, based on Lapua’s testing with its own 26″ test barrel. We observed a speed variance of 67 fps based on tests with three aftermarket barrels.

Barrel Velocity Variance Barrel Velocity Variance

Brand ‘S’ and Brand ‘PN’ were pre-fit barrels shot on Savage actions. Brand ‘K’ was fitted to a custom action. All test barrels were throated for the 100-108 grain bullets, though there may have been some slight variances in barrel freebore. With a COAL of 2.330″, the rounds were “jumping” to the rifling in all barrels.

Among the four barrels, Brand ‘PN’ was the fastest at 2824 fps average — 67 fps faster than the slowest barrel. Roughly 10 fps can be attributed to the slightly longer length (27″ vs. 26″), but otherwise this particular barrel was simply faster than the rest. (Click Here for results of 6mmBR Barrel Length Velocity Test).

IMPORTANT: Results Are Barrel-Specific, Not Brand-Specific

These tests demonstrate that the exact same load can perform very differently in different barrels. We aren’t publishing the barrel-makers’ names, because it would be wrong to assume that ‘Brand X’ is always going to be faster than ‘Brand Y’ based on test results from a single barrel. In fact, velocities can vary up to 100 fps with two identical-spec barrels from the SAME manufacturer. That’s right, you can have two 8-twist, 26″ barrels, with the same land-groove configuration and contour, from the same manufacturer, and one can be much faster than another.

Don’t Demand More Than Your Barrel Can Deliver

We often hear guys lament, “I don’t get it… how can you guys get 2900 fps with your 6BRs and I can only get 2840?” The answer may simply be that the barrel is slower than average. If you have a slow barrel, you can try using more powder, but there is a good chance it may never run as fast as an inherently fast barrel. You shouldn’t knock yourself out (and over-stress your brass) trying to duplicate the velocities someone else may be getting. You need to work within the limits of your barrel.

Factory Ammo Provides a Benchmark

If you have a .223 Rem, 6mmBR, .243 Win, 6.5×47 Lapua, 6.5 Creedmoor, 6.5×55, .308 Win, 30-06, or .338 LM Rifle, we recommend you buy a box of Lapua factory-loaded ammo. This stuff will shoot great (typically around half-MOA), and it can give you a baseline to determine how your barrel stacks up speedwise. [Editor’s NOTE: The original test was conducted in 2008. The velocity of current-production Lapua factory ammo might be higher or lower, so your results may vary.]

When you complete a new 6mmBR rifle, it’s definitely smart to get a box of the factory ammo and chronograph it. That will immediately give you a good idea whether you have a slow, average, or fast barrel. Then you can set your velocity goals accordingly. For example, if the factory 6BR ammo runs about 2780-2790 fps in your gun, it has an average barrel. If it runs 2820+ in a 26″ barrel (or 2835 fps in a 28″), you’ve got a fast tube.

Share the post "Same Ammo in Four Barrels — Surprising Velocity Test Results"

November 10th, 2020

Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads. Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads.

Compared to a .223, the 6BR offers a better selection of high-BC projectiles and small-maker match projectiles (such as Bart Sauter’s “Hammer” and the Vapor Trail line). The 6BR will also deliver considerably more power on the target. Compared to the .308 shooting 168gr MatchKings, a 6BR shooting 105-107gr bullets offers better ballistics all the way out to 1000 yards. (The story changes with .308s with very long barrels pushing the 180-210 grain projectiles). Plus, for most people, the 6BR is just easier to shoot than a .308. Recoil is less than half of the .308 Win cartridge. Both the .308 and 6BR chamberings offer good barrel life, but the 6BR uses 15-18 grains less powder, saving you money. Here’s how the 6BR stacks up vs. a number of popular calibers:

Share the post "Recoil Comparison — .223 Rem vs. 6mmBR vs. .308 Win"

September 8th, 2019

With the 6mm Dasher cartridge becoming popular with PRS/NRL competitors as well as the benchrest crowd, we thought it was time to re-visit a special rifle chambered for the 6mm Dasher wildcat. This gun has a great story behind it. Forum member Bob A. (aka “Killshot”) used his “Forum Classifieds Special” to beat all comers in the F-Class Division in the American-Canadian Match and the Long Range Regional Match in 2013 in Sacramento, CA.

Bob’s 6mm Dasher sports a blue-printed Rem 700 action. Who says you need a high-dollar custom action to run with the big dogs? In fact, this same gun, built with components sourced from AccurateShooter Forum Classified Ads, set a Sacramento F-Class range record of 200-17X a few years back. In this story, Bob talks about the build, and he explains his methods for loading ultra-accurate Dasher ammo.

Bob’s Budget-Build Dasher F-Classer

I wanted to build a proper rifle for F-Open but needed to keep it simple and, well, cheap. I found a solid “base” to build on in the form of a Dave Bruno-built, “pre-owned” 6-6.5×47 Lapua that I located in the AccurateShooter Forum classifieds in late 2011. The base action was a trued and blue-printed Remington 700 receiver circa 1971 with a spiral-fluted bolt. It was in a Shehane ST1000 stock painted sky blue and had a Jewell 1.5-oz BR trigger. I sent the bolt to Greg Tannel (Gretanrifles.com) to have the firing pin hole bushed and sleeved, the ejector removed and the hole filled and the face trued. I upgraded to Tannel’s Light Steel firing pin assembly while it was out.

Having the working bits completed, I needed a barrel. So I went to the AccurateShooter classifieds again and found a 1:8″-twist, 30″ x 1.25″ (diam.) Bartlein with a 0.236″-land bore. I called Dave Kiff and explained my pursuit and he recommended his PT&G “world record” 6 Dasher reamer (.2704″ no-turn neck and .104″ freebore). A month or so later the reamer and gauges arrived.

I had the barrel chambered by Marc Soulie of Spartan Precision Rifles (510-755-5293, Concord, CA). Marc is a great builder and I’m pleased to call him a friend.

The rifle got its good looks from a Pennsylvania artist named Kenny Prahl. His Prahl Designs shop (724-478-2538) added the white ghost-flames over the existing sky blue metallic paint.

Looks Great, Shoots Better

Fire-forming showed great promise — ten-shot groups of half an inch at 200 yards were typical. I lost only one case to a split neck and the “blow lengths” are good and consistent. This was followed up with load development which saw 100-yard, five-shot groups in the .1s and .2s as the rifle showed its preference for Reloder 15 over Varget powder, and for CCI 450s over all other primers. The bullet of choice was the ever-popular Berger 105gr Hybrid Target.

In February 2012 I began shooting the Dasher in monthly club matches at the Sacramento Valley Shooting Center, the home range of a number of excellent F-Class, Benchrest and High Power shooters. Using a Farley Coaxial rest up front (also picked up from a WTB ad on AccurateShooter’s Forum) and an Edgewood bag in the back, I gradually improved my gun-handling to the point where I could shoot a respectable score. This was very different from the bipod shooting I’d done in the past in F/TR.

Dasher Loading Tips Dasher Loading Tips

My chamber is set up for blue box Lapua 6mmBR brass. My case preparation is straight-forward. I fire-form with virgin cases right out of the box. I don’t size them but I will give the primer holes a good look and clean up the flash hole with a .058″ bit in a pin vise. To fire-form, I seat a Berger 108gr BT .030″ into the lands over a standard 6mmBR load of Varget.

For match loads, I use Alliant Reloder 15. While Varget is less sensitive to temp changes, RL15 has given me lower extreme spreads and better long range control. [Bob acknowledges that every barrel is unique, so a different powder, such as H4895 might work better for you.]

I clean my fired cases with stainless steel media in a Thumler’s rotary tumbler after every firing. I anneal after every other firing using a Bench-Source machine which is very well made and easy to operate. I use a Whidden full length bushing die with Redding bushings for sizing.

After sizing, I chamfer the inside of the neck with the K&M tool which has a pilot rod centered in the flash hole. Then I’ll give the neck and mouth a “once over” with some 0000 steel wool. I finish loading off with a Redding Competition Seating Die with the micrometer top.

I use a carbide ball on the expander rod of the full length sizing die. I use a .266″ TiN-coated bushing and the ball just kisses the inside walls of the sized neck. I get very consistent neck tension this way and have had no issue with split necks. I use a carbide ball on the expander rod of the full length sizing die. I use a .266″ TiN-coated bushing and the ball just kisses the inside walls of the sized neck. I get very consistent neck tension this way and have had no issue with split necks.

Seating Depth Considerations

With fire-formed brass, the junction of the bullet’s bearing surface and boat-tail is above the neck/shoulder junction of the case, so I have no issues with donuts. You can see how a loaded round looks in the photo at left. For occasional trimming, I use a very nice little Possum Hollow trimmer that indexes on the case shoulder.

Share the post "Sunday GunDay: 6mm Dasher Winner From Forum Classifieds"

April 11th, 2019

Put the same load in a variety of barrels (with the same length and chamberings) and you’ll see a wide variance in muzzle velocity. In fact, it’s not unusual to see up to 100 fps difference from one barrel to the next. We demonstrated this with a comparison test of Lapua factory ammo.

Chron Testing Lapua Factory Ammo

At our Southern California test range some years ago, we chronographed Lapua 105gr 6mmBR factory ammo in three different 8-twist barrels of similar length. The results were fascinating. Lapua specs this ammo at 2790 fps, based on Lapua’s testing with its own 26″ test barrel. We observed a speed variance of 67 fps based on tests with three aftermarket barrels.

Barrel Velocity Variance Barrel Velocity Variance

Brand ‘S’ and Brand ‘PN’ were pre-fit barrels shot on Savage actions. Brand ‘K’ was fitted to a custom action. All test barrels were throated for the 100-108 grain bullets, though there may have been some slight variances in barrel freebore. With a COAL of 2.330″, the rounds were “jumping” to the rifling in all barrels.

Among the four barrels, Brand ‘PN’ was the fastest at 2824 fps average — 67 fps faster than the slowest barrel. Roughly 10 fps can be attributed to the slightly longer length (27″ vs. 26″), but otherwise this particular barrel was simply faster than the rest. (Click Here for results of 6mmBR Barrel Length Velocity Test).

IMPORTANT: Results Are Barrel-Specific, Not Brand-Specific

These tests demonstrate that the exact same load can perform very differently in different barrels. We aren’t publishing the barrel-makers’ names, because it would be wrong to assume that ‘Brand X’ is always going to be faster than ‘Brand Y’ based on test results from a single barrel. In fact, velocities can vary up to 100 fps with two identical-spec barrels from the SAME manufacturer. That’s right, you can have two 8-twist, 26″ barrels, with the same land-groove configuration and contour, from the same manufacturer, and one can be much faster than another.

Don’t Demand More Than Your Barrel Can Deliver

We often hear guys lament, “I don’t get it… how can you guys get 2900 fps with your 6BRs and I can only get 2840?” The answer may simply be that the barrel is slower than average. If you have a slow barrel, you can try using more powder, but there is a good chance it may never run as fast as an inherently fast barrel. You shouldn’t knock yourself out (and over-stress your brass) trying to duplicate the velocities someone else may be getting. You need to work within the limits of your barrel.

Factory Ammo Provides a Benchmark

If you have a .223 Rem, 6mmBR, .243 Win, 6.5×47 Lapua, 6.5 Creedmoor, 6.5×55, .308 Win, 30-06, or .338 LM Rifle, we recommend you buy a box of Lapua factory-loaded ammo. This stuff will shoot great (typically around half-MOA), and it can give you a baseline to determine how your barrel stacks up speedwise. [Editor’s NOTE: The original test was conducted in 2008. The velocity of current-production Lapua factory ammo might be higher or lower, so your results may vary.]

When you complete a new 6mmBR rifle, it’s definitely smart to get a box of the factory ammo and chronograph it. That will immediately give you a good idea whether you have a slow, average, or fast barrel. Then you can set your velocity goals accordingly. For example, if the factory 6BR ammo runs about 2780-2790 fps in your gun, it has an average barrel. If it runs 2820+ in a 26″ barrel (or 2835 fps in a 28″), you’ve got a fast tube.

Share the post "Velocity Test with Four Different Barrels — Surprising Results"

February 5th, 2019

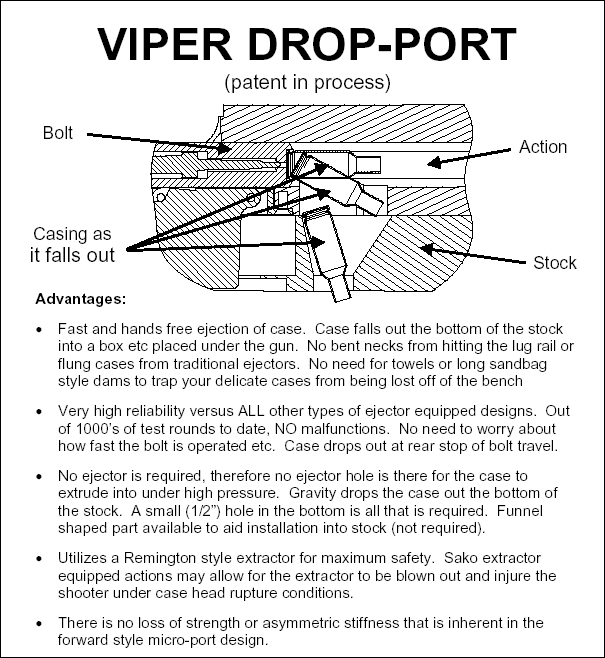

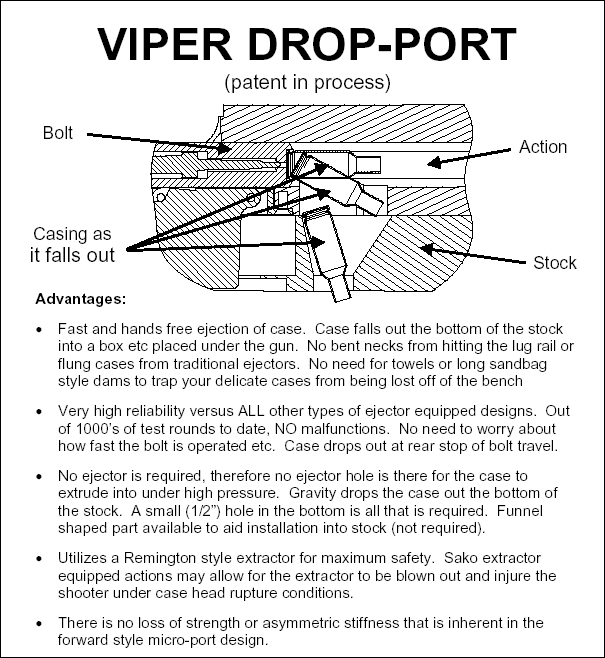

This week we return to our 6mmBR.com roots with an article on David Bergen’s slick 24″ Drop-Port Viper. This was one of the first 6BR rifles we featured. David, who hails from Belgium, developed this project over many months, and the gun proved to be a true tack-driver, with the ability to group in the Ones, even with the heavy boat-tail bullets. David talks about the build and his reloading methods while action designer Jerry Stiller provides technical insights into the design features of his Viper action.

It was a long journey looking for the perfect custom action to build my new rifle. I searched the internet and visited various forums. I even re-read all my old Precision Shooting magazines to find what I was looking for. One evening I conferred by telephone with Mr. Jerry Stiller of Stiller’s Actions in Texas. He patiently answered all my questions. That moment I decided that I wanted a Viper Drop-Port action. [Editor: Sadly, the Viper Drop-Port is no longer in production.]

Component Selection

At the heart of this gun is a Viper action. This medium-sized action can handle cartridges from a small BR up to a 6.5-284. (Stiller’s smaller Cobra action is for PPC and BRs only.) The Viper is milled from aluminum. This keeps weight down while still allowing Vipers to have a large bedding surface like a Stolle Panda.

At first I was a bit sceptical about the aluminum’s toughness, but Mr. Stiller informed me that the action is the perfect marriage between steel and aluminum. The bolt is hard-chromed and the action body is hard-anodized. This gives it two surfaces that resist wear and make an already-slick action even slicker. Stainless steel is used for all the heavy-stress points including barrel threads, locking lugs, and the rear camming surface. The bolt is made of steel with a very light, small-diameter firing pin to prevent primer piercing with heavy loads. Everything is held very concentric to the bore axis. The Viper is a very smooth action mainly because the design and the precise machining of the camming surfaces. Combined with optimal bolt-lift timing, this gives a smooth action. Stiller also keeps the tolerances very tight on these actions, though they are as fast-handling as any you can buy. The trigger is of course a Jewell BR model.

The rifle is chambered in 6mmBR Norma, my favorite cartridge. I have two HV-contour Shilen match barrels, both with 1 in 8″ twists and finished lengths of 24 inches. The chamber has a .266″ neck so neck-turning is necessary. Freebore is .060″ but combined with a 1.5° throat angle this lets me seat a wide range of bullets from 58 grains up to 107 grains.

The stock is a McMillan Edge with moulded-in gray and black marble swirl. I specified 60% black and dark and light gray both at 20%. I went with the Edge stock because I was always pleased with McMillan products and because it had a very low center of gravity. I wanted the barrels very low in the stock because I think it makes the gun track better.

Details of the Drop-Port–with VIDEO! Details of the Drop-Port–with VIDEO!

The visible part of the Drop-Port is a cartridge-sized cut-out in the floor of the action. This tapers into a funnel shape that lets the spent case fall nose-first through a single hole in the underside of the stock. The Drop-Port is carefully sized so that empty brass will fall through from gravity but a loaded round won’t. I’ve found that getting a BR case to eject 100% reliably in a standard action is not easy. The round is short and fat so it clears the chamber too early and the ejector pushes the cases out the extractor too fast. This can result in an empty case sitting in your action, no longer held by the extractor. Needless to say, this can slow you down during a stressful competition. When you get a Drop-Port you can forget all those problems.

Failure to eject is NOT going to happen with a Drop-Port. The system just works every time, and it’s FAST. Right-Click on the Media Player image and “Save As” to download a video (6.9 megs) showing me cycling the action during live fire.

One smart feature of the Drop-Port is the extractor location. A Remington extractor is located at the bottom of the bolt. This way the case is supported by the extractor until the front of the case lines up with the cut-out in the action. At that moment the front of the case tilts down and the rim slips out of the extractor. In the stock there is a funnel which collects the case. The case drops out of the rifle through a single small hole in front of the trigger guard.

Building an Accurate Load Building an Accurate Load

Tools and Recipes

I start with new Lapua cases and after full-length sizing I trim them with a Wilson trimmer. Then I turn the necks for a .264″ neck diameter with a Lapua 105 seated in the brass. After fire-forming I use a “semi-custom” Harrell’s full-length sizing die with bushing. I use a .262 bushing with the moly-coated bullets. This Harrell’s die is the best I ever used — it gives very low run out. [Editor’s Note: Harrell’s stocks a number of dies with various internal dimensions. You send them three fire-formed cases and they’ll pick out a die that fits your brass the best. The cost is very reasonable.] Overall the excellent concentricity I’m seeing with my rounds is a combination of a superb chambering job, a neck-turned Lapua case and the Harrell’s sizing die. The die is supplied with a brass bushing that allows you to measure the amount of sizing you are doing.

For seating I use both a Wilson inline seater (hand die) and a Forster seating die that threads into a press. The latter gets the most use because I find it easier to use. Run out with both is around 0.001″ or better measured on the bullet.

Load development was very easy. I started with Varget and all loads … shot well. Vihtavuori N150 also shot very well with… moly-coated Lapua 105s. To my delight, the light bullets are also shooting very well in the 1:8″ twist. Nosler Ballistic Tips are giving very good results with a case full of N140. I’ve also tried N150, N540 and AA 2520. For all loads I’ve been using CCI BR4. Bullets are seated well into the lands with square marks showing. This gives an overall length around 59 mm (2.32″), depending on the bullet used.

Shooting the Rifle–How It Performs Shooting the Rifle–How It Performs

The rifle is very easy to shoot and it is very accurate, but it had some drawbacks in the beginning. First there is the stock. It is designed for bench shooting and on a table it does this very well. I use a Caldwell front rest and a Protektor rear bag. When shooting prone I’ll also use the rest but the cheek weld is not ideal (the Edge was optimized for free recoil shooting from the bench). The rings that are supplied with the action are rather high. I looked around and found some that were lower. This made shooting easier, but I still wasn’t satisfied. The gun was a bit nose-heavy. There is a weight system built into the stock, but it wasn’t enough to bring the gun in balance. I like the balance point to be just in front of the receiver ring. So I cut the rear off the stock and put in a larger tube and turned some weights to put in it. I also made up an aluminum butt plate. Then I installed a Harrell’s brake to cut recoil to a minimum. With these modifications, the rifle is now shooting the way I want. I think the Edge stock is a very good design for benchrest shooting but for prone shooting it has some shortcomings. I think the MBR is a better stock for shooting prone.

Muzzle Brake–Less Recoil, Same Excellent Accuracy

After testing the barrel with different loads, I decided to put a brake on one barrel. Most of my guns are muzzle-braked and since I had two virtually identical barrels, I put a Harrell’s brake on one. The barrel had to be threaded to mount the brake and here I was a little concerned–I remembered the advice to “never mess with a winner”. The un-braked barrel was ultra-accurate and I was curious whether the process of fitting the brake might affect the accuracy.

Thankfully, my worries were unfounded. My targets showed no loss of accuracy — there was no evidence that the brake had caused any changes (except as to recoil). I have wondered though, perhaps the brake makes the gun more shootable and in that way compensates for some small accuracy loss that may be there? Whatever the case, the gun shoots just as tight as before, except now it’s a lot more user-friendly with less muzzle hop and less “push” on recoil.

This Rifle Literally Shoots Bug-Holes This Rifle Literally Shoots Bug-Holes

And now I come to the end of the story. One day when testing the rifle at 100 meters (with brake installed), I spied a fly on the target. Well now, I thought, here is an interesting “precision shooting” challenge. I put the crosshair on the fly, squeezed the trigger, and the fly was history.

One shot, one kill. Now THAT is impressive precision. If you look closely you’ll see what’s left of Mr. Fly around the bullet hole. Or “bug-hole” as you Americans would say. This kind of performance is a real confidence-booster for the trigger-puller, let me tell you.

The Drop-Port — Simple Yet Advanced

Jerry Stiller tells us: “The drop-port ejects the case out the bottom of the action using only gravity. No ejector plunger is required so the system is as foolproof as anything can be. (A normal spring-loaded ejector creates an uneven load on one side of the case head.) Unlike other ejection systems, micro-ports etc., a Drop-Port doesn’t require tuning or adjusting, and just works. Many top shooters tell us they can cycle rounds faster with a Drop-Port action than with any other design.”

“The engineering of the Viper reflects some key design objectives. I wanted it to be able to fit standard commercially available stocks and have a barrel fit-up that was well known in the industry. I liked the idea of the larger bedding area and higher stiffness of the aluminum actions, so I chose the Panda footprint and barrel tenon for the Viper. I also made some changes to what was available at the time to make the product better. I used a smaller diameter firing pin to eliminate primer piercing, hard anodized all the aluminum parts for corrosion resistance and to make the surface hard and slick. The bolts are also coated for the same reasons.

Drop-Port technical drawing, Copyright © 2005, Stiller’s Precision Firearms, All Rights Reserved.

Share the post "Blast from the Past — 6mmBR Drop-Port Viper"

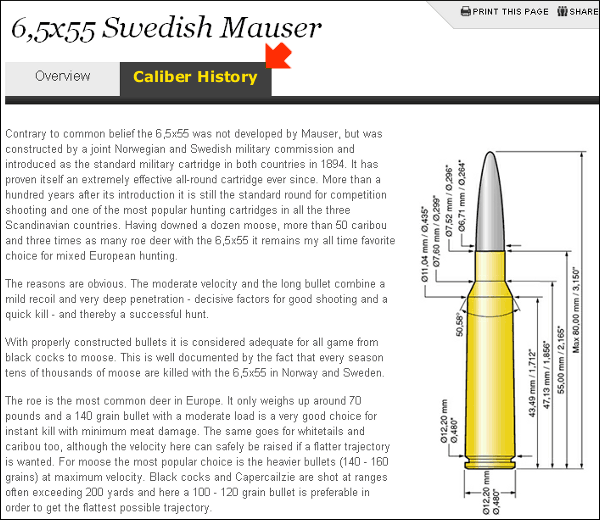

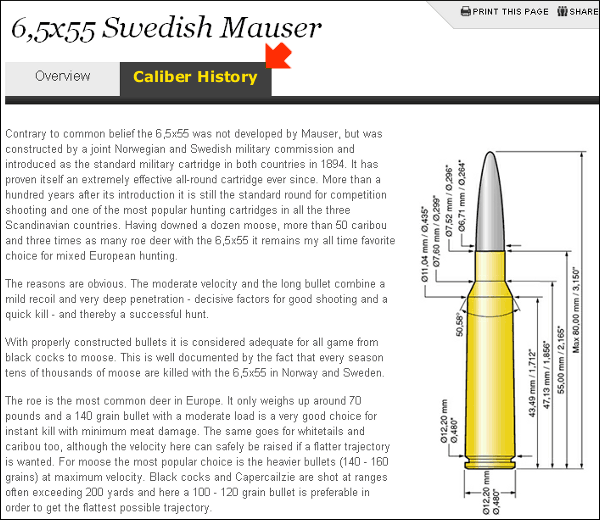

April 5th, 2014

On the Norma website, in the products area, you’ll find dozens of illustrated cartridge profiles. Many of these have been augmented with “Caliber Histories” providing background information, both historical and practical. These entries will benefit those interested in the origins and development of popular hunting and match cartridges. Many of the “Caliber Histories” also include information on bullets and twist rates. On the Norma website, in the products area, you’ll find dozens of illustrated cartridge profiles. Many of these have been augmented with “Caliber Histories” providing background information, both historical and practical. These entries will benefit those interested in the origins and development of popular hunting and match cartridges. Many of the “Caliber Histories” also include information on bullets and twist rates.

CLICK HERE to access the Hunting Products page on Norma’s website. There, on the left, you’ll see a vertical list of 58 different cartridges. Click on any cartridge name and you’ll see an illustrated “overview”. For most (but not all) listed cartridges, there is also a gray tab labeled “Caliber History”. Click that tab to see a cartridge diagram and a few paragraphs explaining the cartridge’s lineage and design features. For example, the .280 Remington Caliber History explains: “This cartridge was constructed in 1957 for Remington’s model 740 Autoloader. It is basically a .30-06 necked down to accept 7mm bullets, but the shoulder was moved forward a little in order to prevent the cartridge from being loaded into .270 Win. rifles by mistake.” Many of the Caliber History entries offer recommended bullet weights and barrel twist rates. Shown below is the 6.5×55 Swede’s Caliber History:

Article tip by EdLongrange. We welcome reader submissions.

Share the post "Norma Website Now Offers Cartridge Histories"

November 25th, 2010

Forum member Jerry S. posted this story yesterday in our Shooters’ Forum. It shows that, with the right bullet and good shot placement, the diminutive 6BR is more than enough cartridge for deer. Forum member Jerry S. posted this story yesterday in our Shooters’ Forum. It shows that, with the right bullet and good shot placement, the diminutive 6BR is more than enough cartridge for deer.

I decided to try something different this year. Instead of dragging out my trusty .44 Smith or the 6.5×55 Remington 700, I took my 6mmBR Norma Prairie Dog rifle deer hunting. We got a lot of wet sloppy snow the week before the opener and had a freezing drizzle on the first morning. I decided to hunt close to the house since my old bones couldn’t handle the trip to my normal hunting stand.

I set the 6mmBR P-dog rifle up on my shooting bench and began the long, cold wait. The deer trail I was watching is about 180 – 230 yards from where I was sitting.

Buck Lined up in Cross-hairs

At about 2:30 this afternoon, I was watching some does feeding along the trail and looked away for a minute then looked back and saw a third deer moving up behind them. A quick check in the spotting scope showed horns and I got behind the rifle. There is no safety on my P-dog gun so it wasn’t loaded and I quickly chambered a round. The does stepped into the woods and the buck stopped for a minute and looked right at me. I centered the cross hairs on his chest and touched the trigger. I could hear the impact as he leaped straight in the air and hit the ground running into the woods.

I figured it was a good hit, so I poured a cup of coffee and relaxed for a bit to let him tire out and drop. After my coffee, I picked up my 6.5×55 and went out to where he was shot. I was 190 yards from my bench and there was no blood. He was headed toward a swamp south of me so I figured I’d cut him off and see if I could cut his trail farther into the bush. I hadn’t gone ten yards when I came across a good blood trail.

I followed it for a few more yards and found him crumpled up. He had only gone 25 yards from where he was shot. While I was looking at him and taking photos, two more deer showed up. You can see one standing on the other side of my rifle.

My buddy brought his 4-wheeler over and helped me drag it to the house where we skinned it out. The bullet had taken the top off the heart and he was totally bled out. All in all, it was a successful hunt, and the 6mmBR did its job.

Share the post "Holiday Hunt — 6mmBR for Deer"

|

George Gardner was kind enough to send us 50 pieces of Pre-Production Alpha 6GT brass for preliminary testing. Like the cases I formed from 6.5×47 Lapua brass, the Alpha 6GT brass will use a small rifle primer. Purchased direct from Alpha Munitions, 6GT brass is now $1.30 per case, which is comparable with Lapua 6mm Creedmoor brass, currently $120.99/100 at Grafs.com.

George Gardner was kind enough to send us 50 pieces of Pre-Production Alpha 6GT brass for preliminary testing. Like the cases I formed from 6.5×47 Lapua brass, the Alpha 6GT brass will use a small rifle primer. Purchased direct from Alpha Munitions, 6GT brass is now $1.30 per case, which is comparable with Lapua 6mm Creedmoor brass, currently $120.99/100 at Grafs.com.

BRASS — The first thing you’ll find is cartridge brass choices for the 6 GT are rather limited currently. At present, the only commercial options are Hornady and Alpha Munitions. For the die-hard Lapua fans, you can technically make 6mm GT brass from 6.5×47 Lapua, however that process is very labor-intensive.

BRASS — The first thing you’ll find is cartridge brass choices for the 6 GT are rather limited currently. At present, the only commercial options are Hornady and Alpha Munitions. For the die-hard Lapua fans, you can technically make 6mm GT brass from 6.5×47 Lapua, however that process is very labor-intensive.

SUMMARY — Good Cartridge with Much Potential

SUMMARY — Good Cartridge with Much Potential

Barrel Velocity Variance

Barrel Velocity Variance

Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads.

Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads.

Dasher Loading Tips

Dasher Loading Tips I use a carbide ball on the expander rod of the full length sizing die. I use a .266″ TiN-coated bushing and the ball just kisses the inside walls of the sized neck. I get very consistent neck tension this way and have had no issue with split necks.

I use a carbide ball on the expander rod of the full length sizing die. I use a .266″ TiN-coated bushing and the ball just kisses the inside walls of the sized neck. I get very consistent neck tension this way and have had no issue with split necks.

Building an Accurate Load

Building an Accurate Load Shooting the Rifle–How It Performs

Shooting the Rifle–How It Performs

This Rifle Literally Shoots Bug-Holes

This Rifle Literally Shoots Bug-Holes

Forum member Jerry S. posted this story yesterday in our

Forum member Jerry S. posted this story yesterday in our