Sunday Gunday: Multi-Tasking .308 Tubegun in Eliseo Chassis

This article features an impressive .308 Winchester tubegun, crafted with an Eliseo (Competition Machine) RTS chassis, Borden action, and 30″ Krieger medium Palma Contour barrel. Owner Mark LaFevers chambered and fitted the barrel and assembled the rifle himself. What’s more, Mark even crafted his own muzzle brake, front/rear bag-riders, and his own, innovative “big-foot” bipod! Mark’s Do-It-Yourself (DIY) tubegun has proven as accurate as it is multi-faceted. Optimized to shoot the 155-grain-class match projectiles, this gun is a tack-driver. This Editor has witnessed the gun repeatedly put 3-round groups into one ragged hole at 100 yards. At 600 yards, the gun has held under 1″ of vertical in competition.

When it comes to versatility, it’s hard to beat a tubegun chambered in .308 Winchester. This rifle system can be used in High Power (Palma) competition, F-TR matches, Long Range Steel Matches, and Tactical Competitions. With the addition of a front sled, a modern tubegun can even be competitive in 600-yard benchrest matches, as demonstrated by Jerry Tierney, who, some years back, won the NBRSA 600-yard Nationals with an Eliseo (Competition Machine) tubegun.

Do-It-All Multi-Discipline .308 Win Tubegun for F-TR, Benchrest, Varmint Matches, Palma, and Tactical Competitions

by Mark LaFevers

The Concept — a ‘Do-It-All .308 Win’

The Concept — a ‘Do-It-All .308 Win’

This project began with a wish list developed after shooting in a precision tactical match in 2009. From that experience I knew I wanted a magazine-fed precision bolt gun sporting a high-quality, variable-power scope. I wanted a rifle that could be competitive in a broad range of gun games including tac comps and long-range prone events. If the gun could also double as a medium-range benchrest rig, that would satisfy the needs of the monthly club matches I shoot — a varmint steel silhouette match (shot from the bench), and an F-Class style prone event. I also wanted a gun that could shoot Palma matches someday (when I get around to learning to shoot with iron sights).

Because I like to build things, I’m always looking for projects that offer opportunities to customize and innovate to suit my needs. And because I’m interested in trying different shooting disciplines, I hoped to craft a rifle that could be reconfigured fairly easily to fit various needs. To maximize the gun’s potential, I chose to use only the highest-quality components for every aspect of this project. I planned on building as much of this rifle as I possibly could myself — and that would include chambering and fitting a barrel for the first time. Having much to learn, I would be relying heavily on the expert advice and goodwill of others for the gun’s success.

The Do-It-Yourself Approach — The Appeal of Building Your Own Rifle

Not everyone understands the DIY (do-it-yourself) approach to life. Why would anyone try to smith his own rifle, when he could have it done by competent professionals? There is the imagined prospect of cost savings. However, a home gunsmith may find that, at least initially, it costs more money to do it yourself when all the costs of tooling etc. are calculated. But doing it yourself is not just about saving money. There is a special satisfaction derived from building something with your own hands. For me the relationship between practiced hands, tools, materials, and knowledge of craft is important. The DIY approach surely means different things to different people. For me it’s about the quest for improvement, and an appreciation of the importance of craftmanship in history, and trying to do my part.

Whatever our craft, the fit and function of the things we care about ultimately define us. In this project I felt a responsibility to uphold certain standards. I also was motivated by the desire to give ‘homage’ to my distant relative Daniel M. LeFever, a gun-maker who left his mark on the firearms industry in the 1870s. “Uncle Dan” LeFever crafted high-grade double guns that rivaled the finest European doubles.*

Choosing Components for the .308 Win Tubegun

Looking over the range of suitable equipment, it did not take long to come across Gary Eliseo’s Competition Machine tubegun chassis kit. Initially intrigued by the beauty of the machine work in this aluminum stock, the more I looked the better this platform seemed. Gary’s RTS kit for Remington 700 and Rem clones accepts the proven AICS magazines and offers great stock adjustment flexibility. For more on that subject read German Salazar’s excellent article on Configuring the Eliseo Tubegun Stock.

When I learned that Jim Borden, BordenRifles.com, was building an action designed specifically for the Eliseo tubegun stock, the decision to go this route was made even easier. I had previously had the opportunity to admire close up the Borden action used by our top Club benchrest record holder, and I knew I couldn’t go wrong there. In selecting a trigger group, I knew I wanted a fully adjustable two-stage trigger that could be set for different pull weights for various shooting disciplines. At first glance Jewell seemed to be the obvious choices, but I asked if there were any products that might be better than the Jewell for my purposes. It was suggested that an American-made trigger by CG Jackson might do the trick, so I talked with Tom Myers of X-Treme Shooting Products. Tom’s company offered a fully-adjustable, 2-stage Mod 22 Tactical trigger that fits Remington 700 actions and their clones. It is offered with a fixed or moveable shoe, with or without a safety. I chose the fixed trigger shoe with no safety.

Choosing a Scope

Given my prior positive experiences with Nightforce products, a Nightforce scope was my first choice in optics. But I needed to select between the NXS (side-focus) and BR (front focus) models, and chose a magnification range. Because I wanted to play a variety of gun games from Tactical to Benchrest, it seemed to me that the NXS, with its faster side focus parallax adjustment, would be the more versatile choice. I went with the 12-42x56mm version so that I had plenty of magnification on tap for long-range precision work. I can still dial it back to 12 power for a wider field of view, as needed.

Mark bench-testing the gun during Load Development. The front rest is the superb SEB Neo Co-Axial.

Caliber Choice and Load Development

Choice of Caliber — .308 Win Offers Accuracy, Versatility, Long Barrel Life

Rather than agonize over the many caliber choices, I chose to step back and consider what I thought, in my experience, made winning shooters. Was it the caliber they were shooting or their training, skill and intelligence, that made them winners? While it is true that various calibers do have their specific merits, it is also true that an individual with five times as much training as you is likely to beat you with whatever caliber he or she is using. Case in point being the tactical match that got me started on this project, won by a young Marine shooting a .308 Win. While many other competitors had rifles with “faster, flatter, superior ballistics”, the Marine topped the field through his superior training, natural ability, and the keen edge of youth. With the right trigger puller, .308 Win was clearly still good enough to win this kind of match.

Among the arguments in favor of the .308 Win caliber for this project were:

- I had positive previous experience with the .308 and was already set up to reload for it.

- Very wide selection of performance-proven bullets.

- Some popular disciplines, such as F-TR and International Fullbore, specify .308 Win (7.62×51) as one of the “permitted” chamberings.

- Top shooters could provide guidance on .308 load development, and effective shooting techniques.

- .308 Win offers long barrel life.

Weighing against the .308 Win were higher component costs and heavier recoil compared to many popular, smaller, mid-distance calibers, such as the 6mmBR, 6 Dasher, 6XC, and 6.5×47 Lapua.

Selecting the Optimal Barrel Configuration for my Bullet Selection

One way of narrowing the field of .308 bullet options is to choose a specific bullet that has performed well for winning shooters, and design the gun around the bullet. The weight of the bullet and its preference for a specific seating depth dictate the twist rate of the barrel and the depth of the chamber, which is also dependent upon whether you choose to single feed or magazine feed. Because I have had very positive experiences with Berger bullets, and becasue Berger Ballistician Bryan Litz was very positive about Berger’s 155.5gr Palma bullet, that was my starting bullet choice for this gun. Because Bryan had great 1000-yard success with a 1:13 twist barrel with the 155.5 bullet, but thought he might go with a 1:12 twist next time, I felt it would be interesting to try a 1:12.5″ twist. Krieger Barrels was able to privde this specific twist rate, and we hoped Krieger’s 5R rifling with a 30″ length would yield a fast barrel. Some extra velocity would help offset the velocity loss I might suffer by being limited to a mag-length COAL. (If I could load longer than mag length I could stuff in more powder and get more velocity.) The Krieger 5R proved a very good choice. From the start the barrel has cleaned up easily, it has delivered awesome accuracy, and it holds very tight elevation at long range. I’ve also been able to achieve very low ES/SD with this Krieger.

Gun Set-Up and Initial Testing

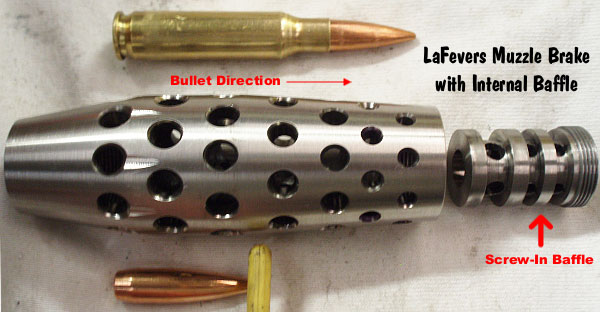

The first break-in of the rifle was done at 100 yards on home turf at the Ojai Valley Gun Club in California. Your Editor and I put 40 rounds through it using Krieger’s recommended break-in procedure. Our impression was that in less than 10 rounds the barrel was ready for competition. I shot the second 10 rounds looking at the performance of the variable muzzle brake I had built. Firing initially with only the one built-in baffle in place, a tremendous amount of gas was still blowing forward, made visually more pronounced by the frosty 29° air. Maximum recoil reduction was achieved adding the front baffle spool, so this is how the brake will be used. On disassembly after firing the forward faces of the baffle spool show descending amounts of powder residue from the gas entry to exit end, with almost no residue at the final baffle wall, showing most of the gas has exited to the side by that point. Attention to precision alignment shows the brake having no adverse effect on accuracy, as the last 20 rounds seated to various depths yielded a couple three-shot, one-hole groups at 100. At the end of the session I was pleased to find that the Krieger barrel cleaned extremely easily. Two wet patches cleared the powder residue and just a little copper showed up at the muzzle end by visual inspection.

The Jim Borden action has a really nice feel when single round loading, and good consistency feeding from the magazine with an authoritative hand. The ejector is very aggressive and will pitch the brass off the bench if it isn’t blocked from escaping. This action cycles very smoothly, and the beautiful workmanship shows even with the tubegun chassis mostly surrounding it.

Mark crafted two front sleds for the gun, one from metal, another from wood (which worked a bit better). Mark notes: “With the wood bag-rider in place the gun became quite stable, and you didn’t notice the high center of gravity so much.” Mark also made his own rear Bag-Rider.

Tubegun Wins First Fun Match

Shortly after breaking in the barrel, I took the gun down to a nearby range to compete in an informal 300- and 400-yard paper competition. I thought it would be fun to test loads while shooting in a club-level fun match. I was getting the best grouping at 44.5 grains of Varget, hotter loads were not doing so well, leading me to believe I needed to work up loads from 44.0 to 44.5 by tenths to find the sweet spot. In the 10-competitor match I squeaked out a win by 1 point. Still, a win is a win!

Load Development

I took the rifle up to the Ojai range at daybreak to run some load variations at 600 yards in still 26° air. I printed targets (sourced from AccurateShooter.com’s FREE Target Page) that had a 1″ red dot within a 5″ grid box. The dot made an excellent aim point at 600 yards. Here the capabilities of the Nightforce 12-42 NXS optic really became apparent. In the exceptionally clear, early morning conditions, I could see the dot AND the bullet holes — all at 600 yards downrange! I had set up my 72-power Meade spotting scope but didn’t use it as the Nightforce scope had more clarity and sharpness. There was no need to go downrange to check the targets, as bullet holes were clearly visible on the targets. This is great because I can make better use of the narrow window of perfect air in the morning, before the sun stirs thermals and mirage.

In this rifle, the Berger 155.5gr Fullbore bullet likes to be seated .010″ off what I’m calling “Max Jam”, using a Hornady OAL length gauge pressing the bullet softly into the lands, so the bullet just barely sticks there when the tool is removed. [Editor’s Note: At his optimal seating depth, Mark’s bullets are still in the lands, just .010″ shy of the max length he can load them without set-back.] The rounds are loaded to 2.850″ OAL to magazine feed. Even though I cut a “no-turn” chamber, I do lightly turn the outside of the case necks to uniform them. I like to look at bullet bearing surface length variations, using a Sinclair comparator body and two .30-cal inserts, one on the nose and the other on the tail of the bullet. With very uniform bullets like the Bergers this method is really only attempting to spot that random outlier bullet that varies in length enough to separate from the group. This is no knock on Berger, just a nod to the challenges of maintaining incredibly tight manufacturing tolerances.

Today’s five shot groups of Varget, jumping by tenths of a grain from 44.0 to 44.5 grains, showed the best grouping to be at 44.1 grains. The hotter loads were breaking the 2900 fps level, but the groups were not as tight as they were at the lower end. At 44.1 grains of Varget the five-shot group had a vertical dispersion of 1.9″ and a horizontal dispersion of 1.25″ at 600 yards, making that a keeper load.

Competition Load Selection and Performance

With a NBRSA 600-yard match fast approaching, I realized that with all the focus on testing I didn’t have enough Lapua brass to shoot the entire match. My solution was to fall back on once-fired Hornady Match brass, with which I have also had excellent luck. So, the day before the NBRSA match, I loaded up the best combinations of the Berger 155.5s with Hornady/Varget, Lapua/Varget, and Hornady/8208 for a final trial, and headed out to a 1000-yard range that’s a two-hour drive from home. Expecting to see the faster IMR 8208 edge out the Varget at this range, I was surprised to see the performance basically identical. With this last minute perspective I decided to shoot the six target NBRSA match using Berger/Hornady/Varget for the first three matches, then Berger/Hornady/8208 for the last three matches when the extra speed might help in a rising afternoon wind.

Match Results

Best results were in Match 1 using 44.0 grains of Varget to push the Berger 155.5 from the Hornady Match brass. Fortunately four bullets flew to a 1.44” group in the blue, unfortunately it was a five-shot match and one bullet flew high left. Excellent promise also showed in Match 6 with the IMR 8208 XBR powder yielding less than an inch of vertical at 600 yards. The lesson I learned from the event was that operator consistency was a much bigger factor than the technical limitations of the hardware or the ammunition. The gun can definitely shoot better than I can hold. I had the opportunity to shoot off a beautiful SEB NEO front rest in this competition. Although I am not a fan yet of joystick controls, this rest performed flawlessly and definitely had a positive effect on performance.

My Overall Impressions of the Project

For use as a benchrest rig, the tubegun provides an interesting challenge, because the pistol grip seems to make the gun much more sensitive to steering errors than a typical low-profile benchrest stock. You have to focus on consistency of grip. A light grip and firm cheek weld combination seems to work well at the bench, but the gun also responds well to a very firm grip and heavy shoulder pressure when fired in the prone position. Building an Eliseo tubegun is a great project and the finished product is a very versatile, fun-to-shoot gun! To encourage others with similar interests, let me just say that the products and components used in this project all get my five-star endorsement, without exception or hesitation.

The biggest challenge with this rifle lies in my own skill development — particularly for tactical matches. If you only have experience with known-distance shooting matches, you’ll need a whole new set of skills to be successful in unknown-distance (UKD) tactical competitions. These UKD matches require high levels of shooting intelligence and training. However, now that I have a rifle that instills confidence, I can work to improve my skills. Overall, I am very happy with the results of this project — the gun has certainly lived up to my expectations. It is rugged, accurate and very adept at “multi-tasking.”

One of my main objectives with this project was to do my own barrel chamber reaming and fit-up work. I had been studying and working from John Hinnants’s excellent book on Precision Rifle Barrel Making, building tools and working with the concepts, and felt myself to be ready to tackle the machining aspects of the project. Having local ace gunsmith Mac Tilton to talk to really helped me understand what would be needed. Greg Tannel’s excellent GreTan DVDs on how to set up a high pressure thru-the-barrel reamer flushing system and align the lathe tailstock properly for precision chamber reaming were invaluable. Greg’s off-the-shelf, hardware-store flow control layout makes the flushing system easy to regulate for other purposes as well. I built the reamer holder Greg describes in his DVD, and it too works well. I began at everyone’s recommended starting point, which was to recheck the level of my lathe, a Jet 1340 gearhead belt-driven model. To accomplish this I used a precision 12” machinist level from Grizzly Tools. I can’t say the tool was easy to use because the leveling process is tedious as hell, but the level worked very well.

Dave Manson Shares His Reamer Knowledge

Chambering Process with Tailstock DRO To shorten this article up a bit and keep it on point for those interested in the rifle and not the process, let me just mention that details of some of the additional parts I made can be seen at my website: LaFeversFabricating.wordpress.com. Those parts include a muzzle brake of my design, my fast attach bipod design, a drop-leg level, wood grip, and wooden as well as metal front and rear bag riders for benchrest work. |

Acknowledgements

For their participation and patience in supporting this project, and their tolerance of my myriad questions about parts and processes, I would like to thank, in alphabetical order:

Berger Bullets — Bergerbullets.com — Berger 155.5gr Fullbore Match bullets.

Jim Borden — BordenRifles.com — Stainless Rem. Clone action for Eliseo tubegun.

Gary Eliseo — CompetitionShootingStuff.com — RTS tubegun stock kit.

Grizzly Industrial — Grizzly.com

Krieger Barrels — KriegerBarrels.com — 30″ Medium Palma, 1:12.5″ twist 5R rifling, tight bore.

Dave Manson — MansonReamers.com — Custom .308 Win finish reamer for Berger 155.5 fullbore bullet.

Tom Myers — X-tremeShooting XTSP — CG Jackson Mod 22 Tactical 2-Stage Trigger.

Nightforce Optics — NightforceOptics.com — 12-42×56 NXS Scope with NP-R1 ranging reticle.

Greg Tannel — GreTanRifles.com — Lathe set-up and chambering DVDs.

*According to Chuck Hawks: “‘Uncle’ Dan Lefever was one of the greatest gun designers of his, or any, time. He founded several companies….The largest and best known of these, Lefever Arms Co., was eventually acquired by the Ithaca Gun Company around the time of the First World War. In the hey day of the classic American double there were guns galore and many different grades and price points, from plain field grade guns to masterpieces rivaling the best European guns. The Lefever Arms guns, for example, won medals at an International Arms Exhibition for ‘Best American’ and ‘World’s Best’ shotgun.”