Shot Order and Calibration When Using Electronic Scales

Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target.

Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target.

Tips on Loading with Electronic Scales

by Kelly Bachand

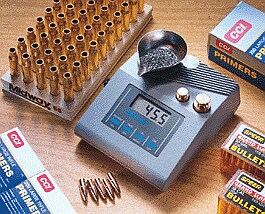

If you use a digital scale to measure powder charges, recalibrate the scale often. I like to do this about every 25 rounds or so. Additionally, most electronic scales rely on eddy currents for their precision. Eddy currents are easily disrupted by static electricity so keep a cloth or ground strap nearby to remove any static currents should the scale start acting up; I usually just use a fabric softener sheet that has gone through the dryer once.

Shoot Ammo in Order of Loading

I shoot my rounds in the same order or reverse order as I load them. If the charge weight varies due to scale drift during use, the difference will be gradual if I shoot in the same order as production (or reverse order). I should be able to adjust for the slight varience in charge weight without having any wildly high or low shots (see the charts below for a graphical demonstration). I usually load my ammunition just 100 rounds at a time. Give yourself plenty of time and remember that you will make your best ammunition when you are fully awake and alert.

This graph demonstrates the effect a .01% (that’s 1/100th of 1 percent) difference in scale measurement would have over the course of 100 rounds assuming the desired load is somewhere between 46 and 47 grains. The final round made would have almost 1% less (or more) powder than the first, that’s almost an 0.5 grain difference from the first. If shot back to back, these rounds will invariably have different points of impact on the target.

This graph demonstrates the same .01% difference in scale measurement but this time with a recalibration every 25 rounds. By recalibrating the scale every 25 rounds the furthest a weighed charge ever gets from the original is less than 0.25%. Again if the charge being weighed is between 46 and 47 grains then the 26th round made would vary from the 1st by .12 grains. Even that small difference would likely show on target.

Either way it is important to note that if the bullets are shot in the same (or reverse) order as they are made, the biggest difference from bullet to bullet in this example is less than .01 grains.

Similar Posts:

- Tech Tip: Reduce Electronic Scales’ Drift with Anti-Static Spray

- TECH Tip: Reduce Electronic Scale Drift with Static Guard Spray

- Weight Drift on Digital Scales

- Wind Box Shelters Scales When Reloading at Outdoor Ranges

- Improve Weighing Consistency by Reducing Static Charge

Tags: Bachand, Calibration, Powder, Reloading, Salazar, Scale

I’m really glad to see this piece by Kelly. He describes the same procedure that I’ve been using for a long time and for the same reasons. Now when my friends tell me I’m crazy I can point them to this well written article as support for my madness! Nicely done!

For a long time when I told people my idea about shooting in the same order as I loaded, they sort of shook their heads or told me it was excessive. It sounds like this was the same treatment you got. They are starting to consider otherwise.

Hello Kelly,

Are you referring to running a complete recalibration cycle every 25 charges, or simply putting an empty pan on and zeroing the scale by hitting ‘TARE’ and allowing it to settle?

I’ve had my fair share (and then some) of headaches with electronic scales over the last few years; I take very little for granted with them any more.

Monte

Monte,

This is just something that was recommended to me when I first started loading and I took it to heart and have always done it.

I do a full recalibration roughly every 25 rounds. For me that means taking the pan off, holding the cal/zero button for 5 seconds, putting the 20g calibration weight on the scale, again pressing the cal/zero button, observing that the correct number shows on the display, then I can put the pan back on the scale before I hit cal/zero one last time making it ready for another 25 rounds.

Kelly

Sounds like you need a better scale..

My ChargeMaster, which is a cheap scale, does not drift near so much as you’re describing. And I have validated it with far more precise scales.

It needs no more than occasional tare with the pan.

A 1% change! NO WAY

Not in a thousand rounds..

There are some important ideas left out here that make the pretty graphes all but useless. One is assuming round to round drift is always biased in the same direction. There may be a statisical trend to sway one way or the other, but this is worst case scenario logic is a poor model and doesn’t compare to empirical evidence. The other is the source of error and understanding how your scale works.

I would challenge individuals to wiegh out their charges, keeping them in order, and then at the end of the process re-wieghing a random selection of them when you are finished. If you are seeing greater change than the advertised accuracy of your scale I would suguest inspecting the environment. Has the room temperature changed? As you in a spot that could get a draft (under a vent?, room has an open door or window?)? Is your scale suseptable to electro-magnetic radiation (Are you playing with your cell phone or wireless hand set, to you have to CRT type TV near by, are you using floresent lighting, do you live under high-tension power lines?)?

There are several source of error in any system: systemic, bias, float, and random. In this write up it completely ignores systemic, bias, and random error and assumes a constant float over time. It’s a start, but has confused truth with preconception on how things work.

Christian,

You raise some good points, but I would like to respond with a ‘real world’ example I encountered with a PACT digital scale. I was weighing bullets for a test and logged each bullet in a table and placed them in order in a loading tray. In the middle of the task I had to take a phone call. 45 minutes later I resumed the job. I had left the last bullet in the scale pan and noticed that the displayed weight was 0.3 grains higher than the recorded weight 45 minutes earlier. I then re-weighed the previous 20 bullets, and every one was exactly 0.3 grains higher.

The drift had occured with time, there were no environmental changes, no flourescent lights, no phones in the room (I had changed locations to take the call). The scale had been calibrated prior to the operation and allowed to “burn in” for two hours before weighing started.

You wrote: “this is worst case scenario logic is a poor model and doesn’t compare to empirical evidence.”

I think you may find that the method recommended may actually be more useful than you think, and the drift we see in our instruments often is time related so a process of loading in order can minimize the shot to shot effects of drift. Of course another option is to use twin scales for control and to calibrate scales very often to “catch” a shift that is subtle and incremental.

Understanding that you experienced drift does not explain how error necessarily came to be. I’m going to assume that the environment in which you measure is stable. There are still variables that have not been isolated. Particularly, a weight (the projectile) was left on the scale. I don’t know how PACT self calibrates, but most scales have it built into their software. If you leave a projectile on the scale, it will drift to a heavier weight, if you take the pan off and then come back, it will drift back down to its calibrated datum. Try it.

If your scale is otherwise unloaded, drifting .3grs in 45 minutes, I would argue it’s time to get a new scale. Also, if your test method doesn’t isolate your variables, your empirical evidence is flawed in that it has a unknown bias. Saying pressure changes the voltage output of the load cell is a bit simplified. It fails to account for signal filtering, quality of input power regulation, and bit loss data truncation once it’s going from analog signal to digital output and through any digital filtering (like self compensating scales). If we don’t know the ins and out of the equipment we are left to make assumptions. Most technology we use isn’t as simple as the classic mechanical methods to understand. The insight we get while using a mechanical method is lost in electronics because of complexities, particularly when we take about sensors. Yes, there is no doubt float was experience in your case. And like other things… float happens. I’ve stepped away from a scale for two days and came back to the same results. If in the time it takes you to measure 100 rounds worth of powder, you are experiencing such a float as presented, what is the point of using the electronic scale? It certainly hasn’t become an aid then.

My skepticism is base around the cause in your case and the frequency in which the article suggests zeroing the scale. In many cases if you are doing enough loading or looking to win a championship or set records, I would recommend a lab quality scale. In time with lesser scales you will most likely experience a significant enough error to make a difference, but a regular load session should not have enough time to cause such variance.

When I first obtained an Acculab scale, I left it on all the time and would note that it would wonder by perhaps even a whole grain over night. Pretty tough to accept that in a loading session, but anything I can do to improve my loads is worth considering.

The time it takes me to throw and weigh 100 charges is perhaps two hours at the outside, so weighing every 25 rounds does not seem excessive. Thanks for the advise Kelly!

Make that calibrating every 25 rounds…

The problem is that this assumes that the scale drifts in a more or less uniform, predictable manner which was not my experience with some of the less expensive ones I tried a few years ago. I am simply not inclined to believe a scale that drifts.

What I’ve noticed with digital reloading scales is that they all drift when not in use. But with frequent use(while charging shells), more recent models don’t. They lock in on zero everytime the pan is reset.

If you were to weigh a charge every 30sec, lifting and re-setting the pan, for hundreds of rounds, you would not see drift at all.

Is anyone seeing the scale off on standard weight checks after a hundred rounds? If you do, you need another scale.

When that PACT scale drifted .3gr over 45min of inactivity, did it read your standard weghts correctly?

A chargeMaster will drift like this when not in use. But it always ‘wakes up’ and reads a reset pan or standard correctly.

I’m sure it’s a side affect of filtering applied, and not a real issue.

I’ve got some 4 figure lab balances here, and at work they don’t wonder at home they do.

interference and noise in the household can be rather strong, perhaps that goes part way to explaining it.. power filtering maybe part of the solution. Interesting tho.. mine too wonder in the same direction consistently as well..

Funny thing how gravity always seems to work the same every time, everywhere. no Drift! Try a beam and ditch the gizmos.

Scott Parker

Hello Shooters:

I have been reloading for about 50 years. I have progressed from balance beam to electronic scales. In my years checking powder loads I have found the following to be true for electronic scales:

1. Leave your scale on for several hours before you start measuring powder and calibrate prior to starting. This will make sure the humidity in the scale components has had time to become consistent. I also wipe my scale down with a used dryer antistatic sheet to get ride of static interference.

2. Turn all fans off.

3. Stay off your cell phone as I have seen my scale read wildly when the plate is empty and I was on the cell phone.

4. Try to use a digital scale that has two decimal points i.e., hundredths of a grain. Most scales on the market only measure to tenths. Is 24.5 grains really 24.5 or 24.51, 24.52,… or 24.59. All will read 24.5 on a single decimal scale. I also use a manual trickler to properly satisfy the exact charge I need. I use a lab-type scale and shield the scale from wind. I make sure available lighting does not interfere with my measurements.

5. Good luck with your scale and loading.

I agree with many of the skeptics who posted above. The assumption that the strain gauge scales induce error in a predictable manner is incorrect. I have personally witnessed randomized error induced causing both higher and lower measurements across a number of the major brands (VIC-123, UniqueTek’s Pro scale, RCBS Chargemaster, and others).

Unfortunately if you want to maintain a consistency between charges, much like in any other real world scenario, you need the right tool for the job and strain gauge scales can only take you so far. If you need more consistency, you’ll need to invest in a laboratory scale using better technology.

Always good to hear others’ techniques. I “shaved” a 22 caliber bullet to weigh exactly the weight of my powder charge and then I can use that periodically to check the scale during the charging of my cases. I got that tip from Wayne Daniels.

Also a minor tip,NEVER wear wool shirts or sweaters while reloading.