|

|

April 1st, 2013

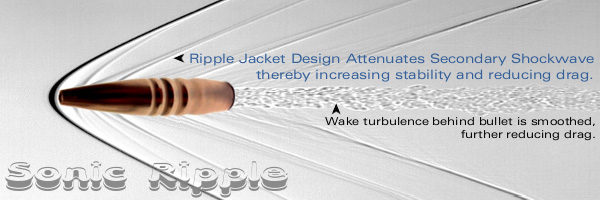

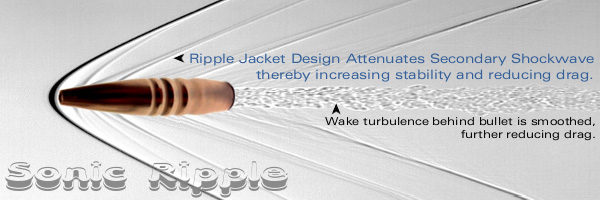

At the end of this year, Berger Bullets plans to introduce a new projectile that may truly be the most revolutionary bullet design since the advent of jacketed spitzers in the late 19th Century. Berger’s new bullet is unlike anything we have ever seen before. It features concentric curved ridges, or “ripples”, on the bearing surface. Tests show that this new projectile, dubbed the “Sonic Ripple Bullet”, has signficantly less drag than conventional bullets (no matter what their ogive configuration). In addition, the Sonic Ripple design provides increased stability at all velocities (allowing barrels with slower twist rates for a given bullet weight).

So, what does all this mean in practical terms? Well, compared to conventional bullets (of similar weight/size), the Sonic Ripple Bullet will shoot a flatter trajectory, buck the wind better, retain energy longer, and remain stable for a much longer distance. That’s big news for competitive shooters, tactical shooters, and long-range hunters.

The Science of the Sonic Ripple Bullet Design The Science of the Sonic Ripple Bullet Design

Bryan Litz, Ballistician for Berger Bullets, explains: “This radical leap forward in bullet design was made possible by advanced, new bullet-making technologies. The unusual bullet appearance is only part of the revolutionary ‘Sonic Ripple’ system. The curvilinear waves or ripples in the bullet jacket are designed to create a specific resonance when fired from a specially ‘tuned’ barrel system. The result is an optimization of the sonic wavefront created by the bullet as it travels through its trajectory. This wavefront optimization simultaneously reduces bullet drag while increasing bullet stability.”

In essence, the supersonic shock-wave is smoothed out, dramatically reducing secondary wave fronts. This is all good, as Bryan explains: “If all the internal ballistic requirements are met, the Sonic Ripple bullet exits the muzzle with a harmonically-stabilized launch dynamic. As a further benefit of the ripple design, tests show that the concentric ripples also enhance boundary layer airflow attachment on the bullet. This, in turn, dramatically reduces wake turbulence and attendant drag.”

The reduction of wake turbulence (combined with wavefront optimization) represents a “major breakthrough” which should increase projectile BC by at least 0.14 (on G7 scale), according to Bryan. But, we wondered, might the increased surface area associated with the ripples slow the bullet down in flight? Actually, no. Bryan explained: “Eddies in the boundary layer around the ripples actually lower skin friction drag which more than compensates for increased surface area, resulting in a net friction drag loss at all velocities — both supersonic and transonic.”

Sonic Ripple Bullets Available by the End of 2013

When will we see Sonic Ripple Bullets on dealers’ shelves? Maybe this year. Berger’s marketing department told us: “The Sonic Ripple technology is currently under development and is expected to mature enough for commercial application by late fall, 2013.”

April 1st, 2013

Are you tired of messing with cleaning rods, bore guides, stinky solvents, and messy JB patches? Can’t wait hours for bore-foam products to work? Well now there’s a new solution ideal for all pistol, shotgun, and rifle shooters. With the new Bore-O-Matic cleaning machine, you can clean your barrels in seconds. Remove copper, powder fouling, and even hard carbon in one ultra-fast operation. The Bore-O-Matic uses a self-deploying snake fitted with a bronze brush to instantly rout out all types of fouling. A powerful 0.5 horsepower electric motor spins the brush at 200 rpm as it snakes its way through your bore, eating away fouling, and leaving a “squeaky clean” interior finish in its wake.

The Bore-O-Matic is easy to use. Simply squirt your favorite solvent* in the barrel, fire up the motor, and let the Bore-O-Matic power its way down your barrel. In seconds you’ll have a perfectly clean bore. Since the Bore-O-Matic’s flexible drive shaft is plastic-coated, no harm can be done.

Bore-O-Matic inventor Tom Bugiardo says that the Bore-O-Matic is perfectly safe for your fine match barrels. “We’ve seen how top competitors brush their barrels like crazy, and frankly, we’re just doing the same thing, but with a motor to minimize the labor.” Additionally, Bugiardo says that the bronze brushes used on the Bore-O-Matic can’t possibly harm your bore. “We all know that bronze is softer than steel so there’s absolutely no risk”. Some potential buyers were worried about the rapidly-spinning bore brushes rounding off the edges of lands or damaging the crown. “Horse-pucky” says Bugiardo, “We’ve researched this extensively on internet gun forums, so we’re 100% confident that running a powered bronze brush at 200 rpm down your barrel can’t harm a thing. Trust us.”

Because the Bore-O-Matic spins as it runs down the bore, gyroscopic forces self-center the cleaning brush. So, no cumbersome (and expensive) bore guides are needed. “Just feed that puppy right down the barrel, and say ‘goodbye’ to barrel fouling forever”, says the inventor.

Along with the $189.99 benchtop Bore-O-Matic unit, a smaller $99.99 hand unit is available. When working in tight spaces, or when cleaning at the range, the battery-powered Bore-O-Matic “Hand-Jobber” is ideal. The Bore-O-Matic handheld unit conveniently fits in a range box and runs off long-lasting, rechargeable Lithium-Ion batteries.

With the compact Bore-O-Matic “Hand-Jobber” you can also easily dip the attached cleaning brush in a tub of JB or Iosso bore cream. Bugiardo tells customers: “Slather that JB on your brush and run ‘er right in the muzzle if you want a mirror finish in your bore. Remember, nothing says ‘pride of ownership’ better than a bore that shines like a spit-polished diamond!”

Currently the Bore-O-Matic is available only from Bugiardo’s company, TB Plumbing Supplies, in Lizella, Georgia (no website yet). Bugiardo expects the product will soon catch on with shooters nationwide and it will be carried by major retailers and online webstores.

*With its high-speed rotary brush, the Bore-O-Matic is so efficient that you don’t need expensive, specialty solvents. Bugiardo uses a simple solution of Windex, Ammonia, Drano Gel, and baking soda. “Makes my barrels shine, inside and out”, Bugiardo says.

April 1st, 2013

The federal Department of Homeland Security (DHS) now has over 200,000 employees and spends upwards of $59,500,000,000 (59.5 billion dollars) annually (See DHS 2013 budget*). Recently, in response to Sequestration cutbacks, DHS released thousands of illegal immigrant detainees, citing budgetary reasons. However, just before the Sequestration went into effect, the DHS managed to find $50,000,000 for new Transportation Safety Authority (TSA) uniforms. With 58,400 TSA employees at present, that works out to $856 per uniform — enough for some mighty fine outfits, as you can see. The federal Department of Homeland Security (DHS) now has over 200,000 employees and spends upwards of $59,500,000,000 (59.5 billion dollars) annually (See DHS 2013 budget*). Recently, in response to Sequestration cutbacks, DHS released thousands of illegal immigrant detainees, citing budgetary reasons. However, just before the Sequestration went into effect, the DHS managed to find $50,000,000 for new Transportation Safety Authority (TSA) uniforms. With 58,400 TSA employees at present, that works out to $856 per uniform — enough for some mighty fine outfits, as you can see.

We wondered what our $50 million tax dollars were buying, so we researched the TSA uniform bid solicitation. Here are exclusive photos of the new TSA uniform designs which have “passed muster” so far. These illustrations show the handsome uniforms selected from the final round of bid submissions, pending Agency approval. We think they look pretty sharp!

Read More about TSA’s $50,000,000 “Sequester-Eve” Uniform Purchase

*The $59.5 Billion-dollar DHS budget works out to $297,500 per worker (for 200,000 DHS employees).

|

The Science of the Sonic Ripple Bullet Design

The Science of the Sonic Ripple Bullet Design

The federal Department of Homeland Security (

The federal Department of Homeland Security (