TECH TIP: Take-Down Procedure for AR Bolt Assembly

Accurate, modular, and supremely versatile, the AR15 is America’s favorite semi-auto rifle. But let’s face it, the AR is a maintenance hog. The AR’s gas tube blows carbon and soot right into the middle of the bolt assembly where it cakes on to the metal. The AR bolt also has many tiny parts, and small recesses, which must be cleaned regularly. This author has seen numerous ARs fail simply because there was gunk (dried lube, carbon, brass shavings) in the ejector slot or extractor spring recess.

A Clean AR is a Happy AR — Whether You Run ‘Wet’ or ‘Dry’

A Clean AR is a Happy AR — Whether You Run ‘Wet’ or ‘Dry’

There are various schools of thought when it comes to maintaining an AR. Some folks prefer to run their AR “dry” with minimal lube on the lugs and friction surfaces. Other shooters prefer to run their ARs “wet”, with lots of lube. But whatever your preference, you need to clean your AR regularly. And nothing is more important than the AR’s bolt/carrier assembly. Because it is involved in feeding, firing, and extracting, the AR-15 bolt/carrier assembly can be considered the most critical portion of the AR-15 from a maintenance standpoint.

Bolt Take-Down Guide on Top Quark Blog

The editor of the Top Quark Blog has created an excellent illustrated AR15 Bolt Take-Down Guide that shows how to disassemble an AR15 bolt and carrier for regular cleaning. Even if you’re an experienced AR15 shooter, you can learn something from this page (sample at right), and you may want to bookmark it for future reference. The photos are large and clear and there are helpful hints for each step of the process.

The author knows his stuff and offers some important insights. For example, he notes that “Extractor springs in most AR15 bolt assemblies are fairly weak, and this can lead to various extraction-related failures. One of the few high points about Colt assemblies is their usage of higher-strength extractor springs. You can tell the difference by looking at the inner plastic insert. ‘Normal’ springs feature a blue plastic insert, Colt strong springs have a black insert.”

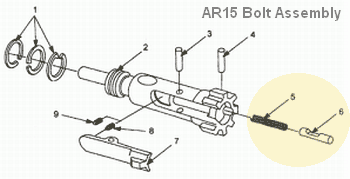

There is one notable oversight on this page — the author doesn’t cover disassembly and cleaning of the ejector assembly. This is actually quite important. A few small brass shavings, combined with carbon and lube in the ejector slot, WILL cause malfunctions. In fact, when this editor is called to diagnose problem ARs, the first things I look at (after swapping magazines) are the ejector recess and the slot for the extractor. Clogged ejectors are responsible for fail-to-ejects and other jams. It is essential that you keep the ejector hole clean. Old, gooey lube residues mixed with carbon and tiny brass shavings in the ejector recess will create all sorts of problems. As shown in the diagram below, it is simple to remove the ejector (#6) and ejector spring (#5), by drifting the ejector retaining pin (#4).

Brownells.com has a nifty tool that’s useful for this process, especially for us older folks [those tiny springs are really hard to locate on the shop floor].

If are not using Slip 2000 Carbon killer to clean your AR type rifle, you are really missing out. I dont’ know what is in this cleaner but it really works and it is not toxic. I usually just dunk my disassemled bolt into the cleaner and come back in 30 mintes and clean it off with a tooth brush. THIS IS THE NUTS!!

Every heard of EAG Tacticals Filthy 14? 40k rounds with minimal maintenance and lots of lube. This level of cleanliness is hardly required on an AR-15 pattern rifle….unless you like to clean.

EDITOR: There are different philosophies when it comes to shooting ARs. I have a Cerakoted carbine that goes long stretches without cleaning. However, I have personally seen MANY ARs that malfunctioned because of a tiny sliver of brass or other debris (combined with sticky lube residue), in the ejector or extractor spring recesses. If you are shooting an AR spacegun in a match (as did High Power Champion Carl Bernosky), you are “playing with fire” if you fail to keep the critical areas of your AR clean. Carbon build-up inside the bolt carrier assembly is another common failure cause.

I agree with most of this, but also have several “match” AR’s that shoot .2’s and .3’s all day long (consistent accuracy) and they have GI uppers, (the ones you call flimsy. Also I’d like to see your injection spots from Testosterone, because you would have to be a monster to flex a (Daniel Defense, RRA, Colt, BCM, etc) with your bare hands. Also a very important factor not mentioned is “neck tension” for accuracy, and I’d highly put it more important that “upper to lower” fit, as well as two tiny set screws putting too much pressure on a .936″ brrl. My best shooting AR has this type of gas block. Military use? Yea F marked FSB pinned or other gas block pinned. If a set screw is putting too much pressure then a clamp on just might “strangle” your barrel. Been to Benning many times, and Perry, and won, along with several egg shoots with a set screw gas block.

You mean you have to clean your rifle, what a novel concept.

The big upside to cleaning is the visual inspection of the bolt group. I’m a clean freak on my defensive guns. But I’ve seen several guns that go thousands of rounds without cleaning. Foreign debris (dirt/sand) is more of a concern than the carbon.

I got a lothar walther barrel from gun broker real cheap a few years ago. I cut my gas block pin slots with a needle file by hand in my apt and when one of the slots was loose I used a coke can shim. That 16″ barrel shoots 1 inch groups with me shooting it prone from a harris with 55 grain FMJ from hornady using my aimpoint red dot sight. I have never cleaned it and shoot it suppressed all the time now that my can was approved. If a gun is throwing pieces of brass into the receiver areas something is wrong with your rifle. AR runs fine with no cleaning. My match upper in 6.5Grendel gets no cleaning as well and I have never had problems with that except for when I run it unsuppressed as the gas system is tuned for the extra pressure.

One thing to release is that there are two different extractor springs using the black insert. The so-called “gold” extractor spring (NSN 1005-01-505-2886) is the current standard for the M16 rifles and M4 carbines procured for the US military. It was adopted for the M4-series back around 2003, and for the M16-series around 2008. The uncolored extractor springs with the black insert (1005-01-424-5899) were still allowed to be used with the M16, but were ultimately to be replaced with the “gold” extractor spring.

anpther expert calling an AR-15 a direct impingment,it is a gas piston operated system the piston just happens to be in the carrier and is combinded with the bolt,just take the piston rings off and see if it still works.for a direct impingment system look up a swedeish lungeman.