AR Ejector Mod For Improved Reliability with Larger Cartridges

TECH TIP by Robert Whitley, AR-X Enterprises LLC

Over the years, while working with various AR-15 cartridges that require a larger bolt-face bolt (i.e. bigger than a 5.56 NATO/.223 Rem bolt-face, like those cartridges that use a 6.8 SPC bolt or the bolt face suitable for the 6.5 Grendel-based cartridges), I have found that there is an increased potential for a certain type of jam if a modification to the standard “Mil-Spec”, square-edged ejector is not made.

The original AR-15 square-edged ejector design was made for a much smaller-diameter bolt face and the smaller diameter 5.56 NATO/.223 Rem case, and it works perfectly in that application. However, as people have adapted the AR-15 platform to shoot bigger cartridges, some parts have been modified to accept the larger cartridges (i.e. bigger bolt-face bolts for the 6.8 SPC and the 6.5 Grendel, and different extractors), yet other parts have been all but ignored. One of these “ignored” parts has been the ejector. Most of the larger-bolt-face AR-15 bolts still use the standard “Mil-Spec”, square-edged 5.56 NATO/.223 Rem. ejector. That’s the problem. But there is a simple, reliable fix!

Chamfering AR Ejector for Improved Reliablity with 6mm, 6.5mm and 6.8mm Cartridges

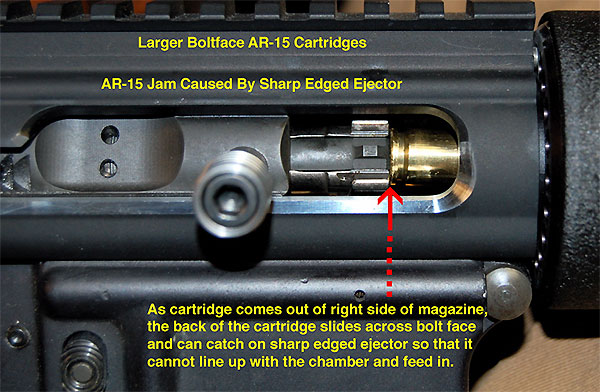

With the larger bolt face and the larger-diameter AR cases, the old-style “Mil-Spec” ejector can cause infrequent but still annoying jams if the ejector is not modified. The jam can occur when a cartridge case feeds up and out of the right side of the magazine, and as it does so, the back of the case must slide across the bolt face and sideways over top of the ejector if it is to center up to the chamber and feed in. If the side of the case catches on the sharp-edged ejector you can get a jam. (See picture above).

Fortunately there is an easy fix for this. One way is to take the ejector out and spin it in a lathe or cordless drill and machine or grind it and round or chamfer the sharp edge. (See picture of rounded ejector next to square edged ejector).

Quick Fix Alternative — Bevel Your Ejector

Another “quick fix” is to leave the ejector in the bolt and chamfer the sharp edge with something like a Dremel tool. (See picture). This fix is easy to do and permanently resolves this potential feeding jam issue. There are no downsides to this modification if done right and I would recommend this modification for the ejectors in all larger bolt-face AR-15 bolts.

This gunsmithing tip provided by Robert Whitley of AR-X Enterprises LLC, 199 North Broad Street, Doylestown, PA 18901. Phone: (215) 348-8789. Website: 6mmAR.com.

Similar Posts:

- Rem 700 Replacement Bolts from PT&G

- How to Blueprint a Rem 700 Action — Rifleshooter.com Reveals

- Blueprinting Rem 700 Action — “How-To” with Rifleshooter.com

- How to Blueprint a Rem 700 Action — RifleShooter.com Report

- Truing a Rem 700 Action — RifleShooter.com Shows the Process

Tags: 6.5 Grendel, 6.8 SPC, 6mmAR, AR, AR Jam Fix, AR Jamming, AR15, Chamfer Ejector, Colt, Ejector, M16, Modern Sporting Rifle, Robert Whitley

Why show the hack dremel tool method? What you did not tell readers is that one nick on the bolt face and it is junk. You should have shown one of the many bolt fixture tools that help to remove the ejector pin. Anyone that owns an AR should own an ejector pin removal fixture to properly disasemble the bolt for cleaning.

Thank you very much. I had this exact problem about every 3rd round on a 6.8 SPC. It did fix the problem.

I am really grateful for this post!

Excellent post! This fixed the problem with a 6br we having issues with as well as 6 grendel wildcat. The dremel fix works well. Yes I took it out to do but have used scared bolt faces in AR`s without issue as well.

Just what I need, grinding dust in my ejector channel, extractor pocket, and firing pin channel.

Take the bolt apart to do this and clean it while you’re at it.Good time to lightly stone the edges of the extractor pocket to get the “sharpies” off too.

A thin, pointed stone is needed for the ejector pocket.

Hi.

THANK YOU. And for those who don’t want to take it out, I used a patch of gorilla tape with a small hole for the pin. Bumping it on accident won’t marr the bolt head. The second format- a single smoothed chamfer – allows for a bigger chamfer overall. EG, can take 1/2 the pin face. Also, the dremel bit shown isn’t the smallest sanding pad you can use. Easier than I thought it would be.

Interesting. I’ve been having jamming issues also on a AR-10 with significant markings on the spent casing. Pulled out the bolt, and the ejector pin is actually protrudes past the bolt face by a millimeter, unlike it being flush in the picture above? Just wondering if I should use the dremel method to shave it down so it’s flush, or take the bolt apart, and shorten the spring?

On an AR10 or 308 AR, just remove the ejector and dome the tip that contacts the brass using the drill and file method.

The ejector is held in place and the height is set by the pin holding it in place, cutting the spring will not change the amount it protrudes.