Sunday GunDay: Cartridges for F-Class — Rise of the Magnums

Cartridges for F-Class Part II — Rise of the Magnums

By Emil Kovan

Kovan Match Rifles LLC, www.matchrifles.com | READ Part I in this Series »

A few seasons back, I wrote an article on cartridge choices for F-Class shooters. CLICK HERE to READ ARTICLE. Since the first article I wrote, F-Class has continued to grow, and push the limits of precision and accuracy. While the .284 Win and its variants are still the most common F-Open cartridges, more and more top F-Open shooters are using magnum cartridge types to win competitions and set new records. In this article, I will list some of the advantages and disadvantages of the most commonly used magnums, and will cover the strengths and weaknesses of each one of them.

Performance factors we will consider for magnum F-Open cartridges include:

1. Equal or better accuracy than standard chambers

2. Better ballistic performance

3. Enhanced case life

4. Barrel life

Accuracy Potential of Magnum Cartridges for F-0pen Competition

John Meyrs has won four National Mid-Range Championships using the .300 WSM. Tim Vought used the same cartridge to win two Mid-Range Nationals and used a 7-6.5 PRC to win the long range Nationals. Standard .437″ case head (.308 Win head size) cartridges still have more Nationals wins overall, but the magnums are quickly catching up, and my prediction is that magnums will dominate soon.

The accuracy and precision potential of magnums used in F-Class (.300 WSM, 7-270 WSM, 7mm RSAUM or “7 SAUM”, 7-6.5 PRC) is better than non-magnum cartridges because their shapes are closer to the ideal “fat/short” body associated with wider nodes and extreme precision. For example a .300 WSM is proportionally much closer to the 6 PPC, 6 Dasher, and 6 BRA than is the .284 Winchester.

Stunning F-Open rifle with SEB Mini front rest with Blake Machine accessories.

The first thing that comes to mind when magnums are discussed is power and speed. In my humble opinion most shooters are missing out on accuracy because they push their magnums right past the most stable and accurate nodes. Recently I met my good friend from the Army Marksmanship Unit, SFC Brandon Green, at a shooting competition. We discussed the latest and greatest in long-range shooting. I knew that the USAMU had switched from 6.5-284 Norma to 7mm RSAUM several years back, but didn’t know what load they are currently using. Brandon told me that the load featured Berger 180gr hybrids in Nosler cases at 2820 fps. We all know that the 7 SAUM is capable of much higher speeds, “but at around 2820 fps the load/rifle combo will hammer the X-Ring anywhere under any conditions” SFC Green said.

F-Open rifles on the firing line at the Ben Avery Shooting Facility in Phoenix, Arizona.

Most shooters jump right into magnum territory velocities when testing, missing out on better precision at standard chamber speeds. For example, my 30 KMR can easily reach 2880 fps with 230gr Hybrids, and it actually shoots pretty good. But the same rifle at around 2770 fps will absolutely hammer the X-Ring in any condition anywhere. When it’s all said and done, F-Class is a long-range shooting competition at a known distance which requires extreme precision and accuracy. It is not a speed race.

IMPORTANT — Case-Head Dimensions Do Make a Difference

Magnums, when shot within reasonable velocities, on average will give better case life due to the bigger case + lower pressure and “more meat” in the case-head area. For example a 7 SAUM case will outlast a .284 Win case when both are loaded to around 2900 fps.

Disadvantages of Magnum F-Open Cartridges

Perhaps the biggest disadvantage linked to magnums is recoil. Some people complain about developing the “gun shy” syndrome after shooting a magnum for a while. Muzzle blast and recoil are significantly more pronounced in magnums, but that can be easily managed with a properly-built rifle equipped with appropriate recoil mitigation hardware such as RAD and the various butt plates.

F-Open rifle equipped with recoil reduction buttpad system.

Barrel Life — “Barrels are Expendable Components”

It is true that certain magnums can torch a barrel in just a few hundred rounds. But the same is true when improving a 6BR to 6 Dasher for example — barrel life might be reduced significantly. More powder = more heat = diminished accuracy after a certain round count. In my experience, a F-Open magnum’s barrel life is very close to high-performance standard cartridges such as the .284 Shehane or .284 KMR. I “retire” my barrels around 1200 rounds regardless of the cartridge being a magnum or not. After that many rounds most barrels will still shoot OK but will copper up, and you will start seeing those unexplained vertical 9s. The bottom line is this, barrels are expendable components very much like brass. You can’t get the performance of .300 WSM and the barrel life of the .308 Win at the same time. If you want to race in NASCAR, fuel mileage should not be the top priority!

Top Magnum Cartridge Types Used in F-Class Open Division

.300 Winchester Short Magnum

The .300 WSM (Winchester Short Magnum) tops the popularity chart in F-Class Open division. It has been used to win numerous National championships and has set many National records. The .300 WSM’s short/fat case shape, with minimal body taper and 35-degree shoulder, contribute greatly to its outstanding performance at long range. Components are readily available as well. Best brass remains to be Norma, although ADG is just as good and some would even say better, but it is more expensive and harder to get at this time.

The .300 WSM has been described as a “super-sized Dasher”.

For the .30-cal magnums, in my opinion, the best bullets by far are made by Berger. If your rifle does not shoot 215gr, 230gr hybrids, or 210gr VLDs well, you likely have a rifle problem, NOT a bullet issue. My “go to” bullet is the Berger 230gr Hybrid. The 215-grainer is a close second, followed by Berger’s accurate but ballistically inferior 210gr VLD, which I use in calm and steady conditions.

Top powders for the .300 WSM are Hodgdon H4831SC and H4350. I know there are many more powders suitable for the .300 WSM cartridge, but none I have used can match Hodgdon’s consistency when shot in different geographical locations and weather conditions.

7mm Remington Short Action Ultra Magnum

The 7mm RSAUM (aka 7 SAUM) used to be the darling of F-Open. Its case capacity and shape are about perfect for launching 180gr pills with great ballistics and precision. Its popularity faded a little, due to the lack of good brass, and the rise of the improved versions of the .284 Win which can almost match the RSAUM performance. Norma still makes 7 RSAUM brass which is pretty good but little on the soft side and hard to find. ADG is arguably producing the best RSAUM brass right now. It is very uniform, reasonably priced, and seems to hold up very well even when pushed hard. The best bullets are again made by Berger, and those are the 180gr hybrid, 184gr hybrid, and 180gr VLD. Best powders are H4831sc, H4350, and Alliant Reloder 16 and Reloder 23.

7-270 WSM, 7-300 WSM, and 7 WSM

The first two are pretty much identical, the only difference being that the 7-270 WSM is necked up .270 WSM while the 7-300 WSM is a .300 WSM necked down to 7mm. I personally prefer the first one since necking-up is easier than necking-down (with fewer doughnut issues).

The WSM case-based 7mms will give you great velocity flexibility as well as superb precision when tuned well. In the 2013 world championship in Raton NM, I was scoring for a gentleman from Canada who was shooting 7-270 WSM. The wind was blowing pretty hard that day. On one of his shots, just before he pulled the trigger the wind gusted. I remember thinking that’s going to be an 8 for sure. The target came up a line 10! I asked him after the match what he was shooting, and he replied 180s at 3100fps. Although capable of such speeds, I think that potentially better and more consistent accuracy can be achieved at much slower speeds. The best powders and bullets are again Hodgdon and Berger respectively. Best cases are made by Norma and ADG, with Winchester being a third option.

7-6.5 PRC — Popular Wildcat

Last but not least on our chart is the 7-6.5 PRC. This particular cartridge is actually a wildcat. It is a 6.5 PRC necked up to 7mm. It is pretty much identical to the 7 RSAUM with the only differences being a shorter neck and .01″-narrower body. Currently the 7-6.5 PRC is the most requested cartridge that I offer when building new rifles. It seems to fill the gap between the .284 Win and the larger magnums very nicely. It is capable of reaching 3000fps but most shooters are getting their best results around 2920-2950 fps. The biggest advantage of this wildcat is brass. Lapua makes super high-quality, readily-available 6.5 PRC brass. Best powders are H4831sc, H4350, Reloder 16, and Vihtavuori VV 555. The best bullet in my opinion is the 180gr Berger. I am yet to hear about a better-performing bullet in this chamber.

Conclusion

In conclusion, magnums are not perfect but their performance advantages should be very seriously considered when building a rifle for long-range F-Class. In part three, I will list the most common wildcat magnums, and present the KMR magnums which will make you (if you haven’t already) buy a magnum action and get a magnum build for sure!

Emil Kovan

Kovan Match Rifles LLC

www.matchrifles.comEmil Kovan Competition History:

– 2014 F-Class Open National Champion

– 2015 F-Class Open National Championship, Silver Medal

– F-Class Open National Championship Teams, 2015, 2014, 2013, Shooting Team Member

– Over 15 wins in Regional and State Championships in Palma, F-TR, F-Open

– 2013 U.S. National Team Member

– 2023 F-Open Gold Medal Team USA Member, 2023 World Championship in South Africa

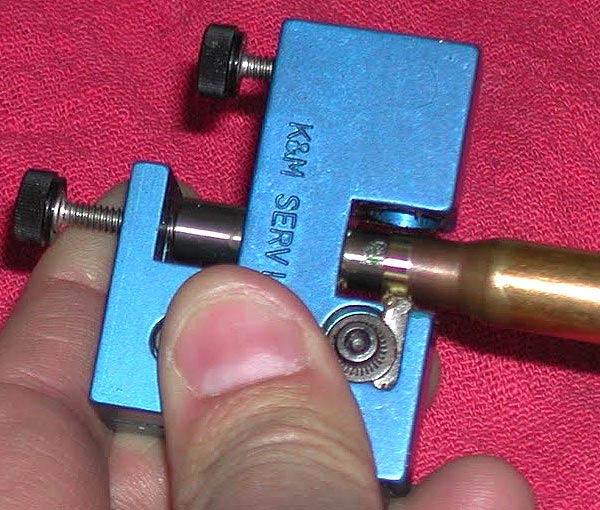

When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder.

When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder.