|

|

July 26th, 2017

“At the start of World War Two, Pratt & Whitney developed a new, ‘B’ series of hydraulically-powered rifling machines, which were in fact two machines on the same bed. They weighed in at three tons and required the concrete floors now generally seen in workshops by this time. Very few of these hydraulic machines subsequently became available on the surplus market and now it is these machines which are sought after and used by barrel makers like John Krieger and ‘Boots’ Obermeyer. In fact, there are probably less of the ‘B’ series hydraulic riflers around today than of the older ‘Sine Bar’ universal riflers.” — Geoffrey Kolbe, Border Barrels.

How Krieger Builds Barrels

This video shows the process of cut-rifled barrel-making by Krieger Barrels, one of the world’s best barrel manufacturers. Krieger cut-rifled barrels have set numerous world records and are favored by many top shooters. The video show the huge, complex machines used — bore-drilling equipment and hydraulic riflers. You can also see how barrels are contoured, polished, and inspected.

Click Arrow to Watch Krieger Barrels Video:

For anyone interested in accurate rifles, this is absolutely a “must-watch” video. Watch blanks being cryogenically treated, then drilled and lathe-turned. Next comes the big stuff — the massive rifling machines that single-point-cut the rifling in a precise, time-consuming process. Following that you can see barrels being contoured, polished, and inspected (with air gauge and bore-scope). There is even a sequence showing chambers being cut.

Here is a time-line of the important barrel-making processes shown in the video. You may want to use the “Pause” button, or repeat some segments to get a better look at particular operations. The numbers on the left represent playback minutes and seconds.

Krieger Barrel-Making Processes Shown in Video:

00:24 – Cryogenic treatment of steel blanks

00:38 – Pre-contour Barrels on CNC lathe

01:14 – Drilling Barrels

01:28 – Finish Turning on CNC lathe

01:40 – Reaming

01:50 – Cut Rifling

02:12 – Hand Lapping

02:25 – Cut Rifling |

02:40 – Finish Lapping

02:55 – Outside Contour Inspection

03:10 – Engraving

03:22 – Polish

03:50 – Fluting

03:56 – Chambering

04:16 – Final Inspection |

August 5th, 2016

Understanding Twist: Bullet Stabilization

by Sierra Bullets Ballistic Technician Paul Box for Sierra Bullets Blog.

Based on the questions we get on a daily basis on our 800 (Customer Support) line, twist is one of the most misunderstood subjects in the gun field. So let’s look deeper into this mystery and get a better understanding of what twist really means.

When you see the term 1:14″ (1-14) or 1:9″ twist, just exactly what does this mean? A rifle having a 1:14″ twist means the bullet will rotate one complete revolution every fourteen inches of the barrel. Naturally a 1:9″ turns one time every nine inches that it travels down the barrel. Now, here’s something that some people have trouble with. I’ve had calls from shooters thinking that a 1:14″ twist was faster than a 1:9″ because the number was higher with the 1:14″. The easiest way to remember this is the higher the number, the slower the twist rate is.

Now, the biggest misconception is that if a shooter has a .223 with a 1:8″ twist, his rifle won’t stabilize a 55gr bullet or anything lighter. So let’s look at what is required. The longer a bullet is for its diameter, the faster the twist has to be to stabilize it. In the case of the .223 with a 1:8″ twist, this was designed to stabilize 80gr bullets in this diameter. In truth the opposite is true. A 1:8″ will spin a 55gr faster than what is required in order to stabilize that length of bullet. If you have a bullet with good concentricity in its jacket, over-spinning it will not [normally] hurt its accuracy potential. [Editor’s Note: In addition, the faster twist rate will not, normally, decrease velocity significantly. That’s been confirmed by testing done by Bryan Litz’s Applied Ballistics Labs. There may be some minor speed loss.]

Many barrel-makers mark the twist rate and bore dimensions on their barrel blanks.

Think of it like tires on your truck. If you have a new set of tires put on your truck, and they balance them proper at the tire shop, you can drive down a street in town at 35 MPH and they spin perfect. You can get out on the highway and drive 65 MPH and they still spin perfect. A bullet acts the same way.

Once I loaded some 35gr HP bullets in a 22-250 Ackley with a 1:8″ twist. After putting three shots down range, the average velocity was 4584 FPS with an RPM level of 412,560. The group measured .750″ at 100 yards. This is a clear example that it is hard to over-stabilize a good bullet.

Twist-rate illustration by Erik Dahlberg courtesy FireArmsID.com. Krieger barrel photo courtesy GS Arizona.

March 3rd, 2016

M-K IIA2 GEN2 Tactical Trigger from The Wisconsin Trigger Co.

Gear Review by Johnny Fisher

Do you shoot an AR-platform rifle? Here’s an excellent trigger upgrade option that has recently returned to the marketplace. The Wisconsin Trigger Company (WITC) has resumed production of the legendary Milazzo-Krieger M-K II trigger for the AR-platform rifles. Not merely marketing a replica of the original Milazzo-Krieger design, Wisconsin Trigger now offers an enhanced, drop-in version called the M-K IIA2. An easy install, the Milazzo-Krieger trigger drops in with no special tools or machining required (and no modification of the safety selector switch).

For those who are looking for an extremely crisp AR15 trigger that closely mirrors the “feel” of a finely tuned M1 / M14 trigger, this trigger might be the solution. The first stage is exceptionally clean and smooth due to a proprietary diamond-grinding process. I felt that the first stage travel was longer than a Geissele, but many guys will prefer that. Upon reaching the very noticeable and defined “wall” of the second stage, a further increase of pressure provides the instantaneous snap one looks for in a high-quality trigger — complete with a total absence of anything resembling creep or slop.

If you follow the instructions in the box and watch WITC’s informative how-to videos, installation of this trigger is extremely straightforward, requiring no special tools or fitting.

As supplied straight from the factory, the first stage requires about 2.25 pounds of take-up before encountering “the wall” of the second stage. For this purpose of this review and to ensure “making weight” in CMP Service Rifle Competitions, the (white) 5-lb. disconnector spring was used. The weight of the second stage came in right at an extremely repeatable 5 lb. 3 oz. (averaging +/- 1.5 oz.) for a ratio of about 40/60 between the two.

Upon release of the hammer, the disconnector reset is decidedly short. National Match shooters in particular will appreciate the very short but easy-to-recognize trigger reset during rapid-fire strings.

Tuning the Trigger Before Installation

As with most National Match-grade triggers on the market, the Millazo-Krieger utilizes proprietary pins that come supplied with this unit. They must be used for final installation and are purposely oversized to a specific diameter for a very snug fit. This is to ensure the trigger and hammer rotate solely on the pins, as opposed to the pins eventually rotating inside the receiver. It is best to use standard sized mil-spec trigger and hammer pins for the setting of tensions (trigger weight) before final installation to help avoid undue wear to the receiver pin holes. Final adjustment of second-stage pull weight must be done BEFORE final installation.

It is recommended to first set the amount of desired disconnector engagement by performing a very simple process that is detailed in the included installation instructions from the TOP of the trigger. The swapping out of disconnector springs and final tuning of the second stage can then be done, but only from UNDERNEATH a disassembled trigger.

The disconnector tensioning springs are easily swapped out by removing the spring plug from the bottom of the trigger housing that exposes the spring pocket. After inserting the desired weight spring, the spring plug must be installed at least flush with the bottom of the trigger housing. Installing it deeper will add trigger pull weight on the second stage. Installing it too shallow will interfere with trigger movement.

Transferable Warrnty: Transferable Warrnty:

The Wisconsin Trigger Company offers a full lifetime warranty to all unaltered parts of its triggers. This lifetime warranty is fully transferable when the trigger is sold to a new user! When have you heard of an AR component manufacturer with a transferable warranty — we’re impressed.

Not just a retailer, John Scandale of Keystone Accuracy is a distributor of these triggers. He currently has many in stock and for sale at a very special introductory price.

What Comes in the Box:

The $265.75 trigger kits come complete with everything you need: Trigger unit assembly, trigger return spring, full strength hammer spring, two proprietary oversized trigger & hammer pivot pins and three disconnector tensioning springs (3.25 lb., 4.5 lb., 5.0 lb.). Also included is a comprehensive installation manual, a color-coded disconnector spring selection chart, some promotional items, and the lifetime warranty card.

January 20th, 2016

SHOT Show offers a unique opportunity to see a host of new products AND reconnect with old friends in the shooting world. We met with our friends John Krieger (Krieger Barrels), Ian Kelbly (Kelblys.com), Dave Kiff (PT&G), and Eric Stecker (Berger Bullets). On SHOT Show Day One we saw many interesting items, including a new $1500.00, 15-60x52mm comp scope from Vortex and the amazing Bix’n Andy Elypse action. That 15-60X Vortex should prove a great choice for F-Class competition and the Elypse “raises the bar” for lightweight benchrest actions.

Vortex Optics — “Golden Eagle” 15-60x52mm Competition Scope

Everyone involved in long-range target shooting should check out this New Vortex “Golden Eagle” 15-60x52mm scope. It offers a 4X zoom ratio with 60X max magnification, with an affordable street price of around $1500.00. That undercuts the competition from other major brands by hundreds of dollars. Two reticle options will be offered, a fine cross-hair and one with MOA-based hold-over lines. We’ll provide a more complete report soon….

Howa — Mini-Action Bolt Gun

We finally got our hands on the Mini-action Howa, a very nice little rifle. I immediately noticed that the bolt is extremely smooth — really nice. The HACT 2-stage trigger is excellent — just about perfect for a varmint rifle. The action is nearly an inch shorter than a conventional “short action” so bolt movement is shorter. The rifle is currently offered in .204 Ruger and .223 Remington, and Howa may release a .222 Remington, 6.5 Grendel and 7.62×39 version in the future. Street price on this rifle is around $600.00. I give this rifle two thumbs up, way up. I want one.

Kelbly’s — New Composite GRS Stocks

Kelbly’s is the North American distributor for GRS stocks from Norway. For 2016 GRS has introduced advanced composite stocks. These share the ergonomic design of GRS wood stocks, but offer greater strength, rigidity, and durability. If you are looking for an advanced composite-matrix stock for hunting and tactical applications, you should check out this new GRS. We were very impressed.

Bix’n Andy — Titanium Elypse Action

This may be the most sophisticated benchrest action ever created. The new Bix’n Andy Elypse action will be offered in both stainless and Titanium (shown above). The action features an elliptical profile and a drop port. The trigger, sold separately, is superb, absolutely superb. There are many unique features, such as the flared loading port ramp and easy-change bolt handle. This is truly the Rolls-Royce of precision actions.

Shilen — AR and Savage Drop-in Barrels

We visited the Shilen booth and chatted with Wade Hull, Shilen’s President. Wade explained that Shilen now offers a variety of Drop-in Barrels for Savages as well as “large-format” ARs (AR10 type rifles in 308-family chamberings). Wade also noted that Shilen has streamlined its production process, so wait-time on chambering work has been reduced significantly.

Stocky’s Stocks — New 3D-Printed Prototype Stock

3D Printing and Rapid Prototyping has come to the gunstock world. Stockys Stocks showed off a high-tech 3D-printed prototype of its new tactical stock with removable cheekpiece. We also checked out Stocky’s impressive Long Range composite stocks. Very strong, and very rigid, these stocks feature a CNC-milled aluminum bedding block. These are a stunning value for just $199.99.

RAS Tuners — Combo Tuner + Muzzle Brake

Tuners work — though it may take a bit of time and effort to dial in your tune. The RAS Tuner system combines a sensitive tuner with a removable muzzle brake. There are systems for ARs as well as bolt guns. The inventor of the RAS says he has seen significant reductions in group size.

Tactical Solutions — High-Bling Rimfire Rifles and Pistols

If bling is your thing, then Idaho-based Tactical Solutions has you covered. This company offers a wide variety of firearms including .22 LR rimfire target pistols and rifles. The rifle in this photo is configured with a permanent barrel extension that makes it ATF-compliant. But the actual barrel is threaded below the barrel extension so you can add a suppressor and still have a short overall-length “fun gun”.

Hygenall — LeadOff Products

Anyone who does a lot of shooting may be exposed to lead residues. Lead is a tough substance to remove from human skin. We chatted with the scientists who created these LeadOff products and were quite impressed. The product uses sophisticated chemistry to “grab and remove” the lead molecules on your skin. This product has earned health agency certifications.

Champion — Plinking Targets for Fun Shooting

Among all the “Operator-ready” Black Rifles and Tactical gear, it was nice to see a display dedicated to the simple fun of shooting. As kids, we all started our shooting careers plinking with a BB Gun or a simple rimfire rifle. Champion makes a variety of reactive targets that are great for plinking.

October 19th, 2015

Here’s something you’ve probably never seen before — a liquid-cooled benchrest rifle. No, this is not just a crazy experiment. This gun, built by Joel Pendergraft, produced a 10-shot, 3.044″ group that is still listed as the International Benchrest Shooters (IBS) 1000-Yard Heavy Gun record. Using this water-cooled 300 Ackley Improved, Joel shot the record group in April 2009 at Hawks Ridge, NC. This monster features a 12-twist, 4-groove Krieger barrel. Joel shot BIB 187gr flat-based bullets in Norma brass, pushed by a “generous amount” of Alliant Reloder 25 and Federal 210M primers.

This 3.044″ 10-shot group was a remarkable accomplishment, breaking one of the longest-standing, 1000-yard World Records.

Pendergraft was modest after his notable achievement: “What makes this so very special is to be able to celebrate the accomplishment with all of my shooting friends[.] A good friend once said that records are shot when preparation and opportunity meet. I feel blessed to have personally had the opportunity. The preparation we can individually work on and achieve but the opportunity only comes to a few. Those of you that compete in long range competition will know what I mean.”

September 18th, 2014

Have you ever wondered how a cut-rifled barrel is made? This process, used by leading barrel-makers such as Bartlein, Border, Brux, Krieger, and Obermeyer, can yield a very high-quality barrel with a long useful life. Cut-rifled barrels have been at the top in short- and long-range benchrest competition in recent years, and cut-rifled barrels have long been popular with F-Class and High Power shooters.

You may be surprised to learn that cut-rifling is probably the oldest method of rifling a barrel. Invented in Nuremberg around 1520, the cut-rifling technique creates spiral grooves in the barrel by removing steel using some form of cutter. In its traditional form, cut rifling may be described as a single-point cutting system using a “hook” cutter. The cutter rests in the cutter box, a hardened steel cylinder made so it will just fit the reamed barrel blank and which also contains the cutter raising mechanism.

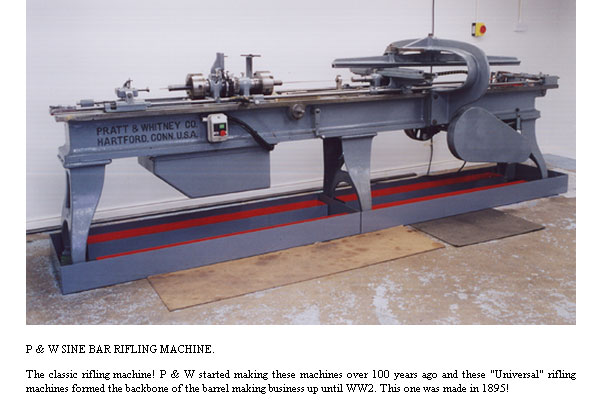

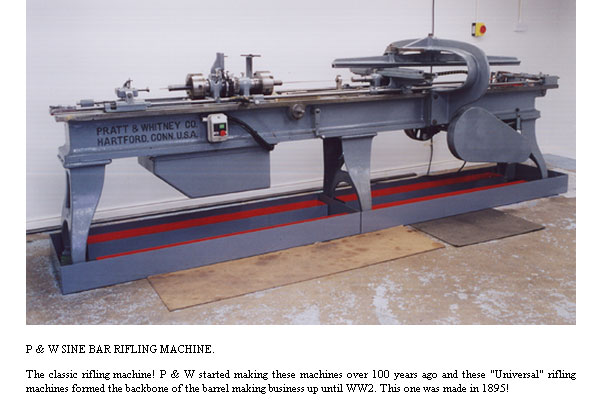

Above is a computer animation of an older style, sine-bar cut-rifling machine. Some machine features have been simplified for the purposes of illustration, but the basic operation is correctly shown. No, the cut-rifling machines at Krieger don’t use a hand-crank, but the mechanical process shown in this video is very similar to the way cut-rifling is done with more modern machines.

Read About Cut-Rifling Process at Border-Barrels.com

Read About Cut-Rifling Process at Border-Barrels.com

To learn more about the barrel-making process, and cut-rifling in particular, visit FirearmsID.com. There you’ll find a “must-read” article by Dr. Geoffrey Kolbe: The Making of a Rifled Barrel. This article describes in detail how barrels are crafted, using both cut-rifling and button-rifling methods. Kolbe (past owner of Border Barrels) covers all the important processes: steel selection, hole drilling, hole reaming, and rifling (by various means). You’ll find a very extensive discussion of how rifling machines work. Here’s a short sample:

“At the start of World War Two, Pratt & Whitney developed a new, ‘B’ series of hydraulically-powered rifling machines, which were in fact two machines on the same bed. They weighed in at three tons and required the concrete floors now generally seen in workshops by this time. About two thousand were built to satisfy the new demand for rifle barrels, but many were broken up after the war or sold to emerging third world countries building up their own arms industry.

Very few of these hydraulic machines subsequently became available on the surplus market and now it is these machines which are sought after and used by barrel makers like John Krieger and ‘Boots’ Obermeyer. In fact, there are probably less of the ‘B’ series hydraulic riflers around today than of the older ‘Sine Bar’ universal riflers.

The techniques of cut rifling have not stood still since the end of the war though. Largely due to the efforts of Boots Obermeyer the design, manufacture and maintenance of the hook cutter and the cutter box have been refined and developed so that barrels of superb accuracy have come from his shop. Cut rifled barrel makers like John Krieger (Krieger Barrels), Mark Chanlyn (Rocky Mountain Rifle Works) and Cliff Labounty (Labounty Precision Reboring)… learned much of their art from Boots Obermeyer, as did I.” — Geoffrey Kolbe

Video find by Boyd Allen. Archive photos from Border-Barrels.com. In June 2013, Birmingham Gunmakers Ltd. acquired Border Barrels. Dr. Geoffrey Koble continues to work for Border Barrels, which maintains operations in Scotland.

May 7th, 2014

Forum member Eric has built an innovative specialty pistol for long-range benchrest. The gun is chambered in 6.5-284 and built for IBS 1000-yard shooting. Eric originally built the gun with a 3″-wide fore-end, then decided to go with a 6″-wide offset design since the IBS no longer restricts Light Gun Forearms to three inches. Eric explained: “After building the 3″-wide stock I looked at the IBS 1000-yard benchrest rules and found out that there was not a width limit and rails were allowed for a Light Gun stock. I set out to design a 6″ version. I was thinking it should be offset also to help control torque and track straighter. I had a new 6.5mm, 1:8.5″ twist, 1.250″ HV-contour Krieger barrel. I chambered the barrel for 6.5-284 and bedded the stock.”

Eric feeds his pistol Sierra 142gr MatchKings with a load of 51.0 grains of H4831sc. Estimated muzzle velocity with this load is 2900 fps — respectable speed from the short barrel. The gun tracks remarkably well, with very little torque effect, as you can see in the video below.

After initial testing, Eric added a muzzle brake to the barrel. This tamed the recoil considerably. To learn more about Eric’s long-range 6.5-284 pistol, visit our Shooters Forum and READ this POST. To see more videos of the pistol in action (with muzzle brake), visit Eric’s PhotoBucket Album.

March 3rd, 2014

Krieger Barrels Inc. is a family-run business. Founder John Krieger now works with two of his sons in the business, Andrew (“Andy”) and Mark. At SHOT Show 2014 we had a chance to chat with John and Andy. John told us that he is very proud to work with his two sons. He said that Andy, who has a degree in engineering, brings an important skill set and a new level of scientific expertise to the business. On his part, Andy says that his father is a “great boss… and the best teacher you could have”. Meet this father and son barrel-making team in this short video. Krieger Barrels Inc. is a family-run business. Founder John Krieger now works with two of his sons in the business, Andrew (“Andy”) and Mark. At SHOT Show 2014 we had a chance to chat with John and Andy. John told us that he is very proud to work with his two sons. He said that Andy, who has a degree in engineering, brings an important skill set and a new level of scientific expertise to the business. On his part, Andy says that his father is a “great boss… and the best teacher you could have”. Meet this father and son barrel-making team in this short video.

John Krieger and Andrew Krieger

How does Krieger Barrels produce such a great product year in and year out? It takes a lot of highly-skilled labor and some serious machinery to produce outstanding cut-rifled barrels. To illustrate the barrel-making process, Krieger has produced a fascinating video, filmed at Krieger’s production facility in Richfield, Wisconsin. This video shows the process of single-point, cut-rifled barrel-making start to finish. If you love big, powerful machines, you’ll enjoy this video. Its really quite amazing to see all that’s involved in the production of cut-rifled barrels.

How Krieger Barrels Are Made (MUST-WATCH video — one of the best we’ve ever featured).

For anyone interested in accurate rifles, this is absolutely a “must-watch” video. Watch blanks being cryogenically treated, then drilled and lathe-turned. Next comes the big stuff — the massive rifling machines that single-point-cut the rifling in a precise, time-consuming process. Following that you can see barrels being contoured, polished, and inspected (with air gauge and bore-scope). There is even a sequence showing chambers being cut.

Here is a time-line of the important barrel-making processes shown in the video. You may want to use the “Pause” button, or repeat some segments to get a better look at particular operations. The numbers on the left represent playback minutes and seconds.

Krieger Barrel-Making Processes Shown in Video

00:24 – Cryogenic treatment of steel blanks

00:38 – Pre-contour Barrels on CNC lathe

01:14 – Drilling Barrels

01:28 – Finish Turning on CNC lathe

01:40 – Reaming

01:50 – Cut Rifling

02:12 – Hand Lapping

02:25 – Cut Rifling

02:40 – Finish Lapping

02:55 – Outside Contour Inspection

03:10 – Engraving

03:22 – Polish

03:50 – Fluting

03:56 – Chambering

04:16 – Final Inspection

March 25th, 2013

Sometimes you’ll get a barrel that doesn’t stabilize bullets the way you’d anticipate, based on the stated (or presumed) twist rate. A barrel might have 1:10″ stamped on the side but it is, in truth, a 1:10.5″ twist or even a 1:9.5″. Cut-rifled barrels, such as Kriegers and Bartleins, normally hold very true to the specified twist rate. With buttoned barrels, due to the nature of the rifling process, there’s a greater chance of a small variation in twist rate. And yes, factory barrels can be slightly out of spec as well. Sometimes you’ll get a barrel that doesn’t stabilize bullets the way you’d anticipate, based on the stated (or presumed) twist rate. A barrel might have 1:10″ stamped on the side but it is, in truth, a 1:10.5″ twist or even a 1:9.5″. Cut-rifled barrels, such as Kriegers and Bartleins, normally hold very true to the specified twist rate. With buttoned barrels, due to the nature of the rifling process, there’s a greater chance of a small variation in twist rate. And yes, factory barrels can be slightly out of spec as well.

Before you purchase a bunch of bullets and set off to develop loads it’s wise to determine the true twist rate of your new barrel. Sinclair International, in its Reloading Press Blog provides a simple procedure for determining the actual twist rate of your barrel. Read on to learn how….

How Twist Rate Affects Bullet Stability

Most of you know that the twist of the rifling in the barrel is what puts spin on the bullet. As a bullet is pushed down the barrel and compressed into the rifling, the bullet follows the path or twist of the rifling. The combination of velocity and bullet spin is what stabilizes the bullet. Finding the twist rate for your barrel will help you in selecting appropriate weight bullets for your firearm. Remember, the general rule is that the faster the twist rate for a given caliber, the longer the bullet (of that caliber) you will be able to stabilize. (Generally speaking, a longer bullet will also be a heavier bullet, but the bullet geometry dictates the needed twist rather than the weight per se.)

Determining Barrel Twist Rate Empirically

Twist rate is defined as the distance in inches of barrel that the rifling takes to make one complete revolution. An example would be a 1:10″ twist rate. A 1:10″ barrel has rifling that makes one complete revolution in 10 inches of barrel length. Rifle manufacturers usually publish twist rates for their standard rifle offerings and custom barrels are always ordered by caliber, contour, and twist rate. If you are having a custom barrel chambered you can ask the gunsmith to mark the barrel with the twist rate.

Erik Dahlberg illustration courtesy FireArmsID.com.

Sinclair’s Simple Twist Rate Measurement Method

If are unsure of the twist rate of the barrel, you can measure it yourself in a couple of minutes. You need a good cleaning rod with a rotating handle and a jag with a fairly tight fitting patch. Utilize a rod guide if you are accessing the barrel through the breech or a muzzle guide if you are going to come in from the muzzle end. Make sure the rod rotates freely in the handle under load. Start the patch into the barrel for a few inches and then stop. Put a piece of tape at the back of the rod by the handle (like a flag) or mark the rod in some way. Measure how much of the rod is still protruding from the rod guide. You can either measure from the rod guide or muzzle guide back to the flag or to a spot on the handle. Next, continue to push the rod in until the mark or tape flag has made one complete revolution. Re-measure the amount of rod that is left sticking out of the barrel. Use the same reference marks as you did on the first measurement. Next, subtract this measurement from the first measurement. This number is the twist rate. For example, if the rod has 24 inches remaining at the start and 16 inches remain after making one revolution, you have 8 inches of travel, thus a 1:8 twist barrel.

This rifling illustration was created by Danish graphic artist Erik Dahlberg. It is published here courtesy FireArmsID.com, an excellent website for forensic firearms examiners.

March 16th, 2012

The Hickory Groundhog and Egg Shoot, the richest varmint shoot East of the Mississippi, is just three weeks away. The hugely popular Hickory Shoot will be held this year on Saturday, April 7, 2012. The basic entry fee is just $25.00 per gun. That’s cheap for a chance to win a bundle of cash, plus valuable prizes such as Shehane stocks and Nightforce optics.

Anatomy of a Hickory-Winning Rig — Brady’s Record-Setting 6BR

If you wonder what kind of rifle can win the big money at the Hickory Shoot, have a look at Terry Brady’s 42-lb 6BR. In 2010, Terry Brady won the Custom Class in the Hickory Shoot, setting an all-time record with a 99 score*. Terry was shooting a straight 6mmBR with 105gr Berger VLD bullets. His rifle looks “normal”, but it was actually purpose-built for Groundhog shoots, which have no weight limit in Custom Class. The fiberglass Shehane Tracker stock was stuffed with lead shot from stem to stern, so that the gun weighs nearly 42 pounds with optics. The Hickory winner, smithed by Mike Davis of Zionville, NC, featured a BAT DS action with a straight-contour, gain-twist Krieger barrel. The twist rate starts at 1:8.7″ and increases to 1:8.3″ at the muzzle. Terry was shooting a relatively moderate load of 30.5 grains Varget with Danzac-coated bullets. This load absolutely hammered, but Terry thinks the gun might shoot even better if the load was “hotted up a little.”

Minimal Recoil and Insane Accuracy at 500 yards

In the picture above you see the Hickory winner fitted with a 5″-wide front plate. This was crafted from aluminum by Gordy Gritters, and Terry said “it only adds a few ounces” to the gun. Mike Davis installed threaded anchors in the fore-end so the plate can be removed for events where forearm width is restricted to 3″. The plate is symmetrical, adding 1″ extra width on either side of the Shehane Tracker stock. Gordy can also craft a 5″ plate that offsets the rifle to one side or the other. Terry hasn’t experimented with an offset front bag-rider, but he thinks it might work well with a heavier-recoiling caliber. Terry actually shot most of the Hickory match without the front plate so he could use his regular 3″-wide front bag. Even with the plate removed, Terry’s Hickory-winning 6BR barely moves on the bags during recoil, according to Terry: “You just pull the trigger and with a little push you’re right back on target.” With this gun, Terry, his son Chris, Chris’s girlfriend Jessica, and Terry’s friend Ben Yarborough nailed an egg at 500 yards four times in a row. That’s impressive accuracy.

*The Hickory employs “worst-edge” scoring, meaning if you cut a scoring line you get the next lower score. One of Terry’s shots was right on the edge of the white and another was centered right between white and black at 3 o’clock. Accordingly he only received 27 points for each of the 300 and 500-yard stages. Under “best-edge” scoring, Terry would have scored even higher.

CLICK HERE for 2012 Hickory Groundhog & Egg Shoot Info Sheet (PDF)

|

Transferable Warrnty:

Transferable Warrnty:

Sometimes you’ll get a barrel that doesn’t stabilize bullets the way you’d anticipate, based on the stated (or presumed) twist rate. A barrel might have 1:10″ stamped on the side but it is, in truth, a 1:10.5″ twist or even a 1:9.5″. Cut-rifled barrels, such as Kriegers and Bartleins, normally hold very true to the specified twist rate. With buttoned barrels, due to the nature of the rifling process, there’s a greater chance of a small variation in twist rate. And yes, factory barrels can be slightly out of spec as well.

Sometimes you’ll get a barrel that doesn’t stabilize bullets the way you’d anticipate, based on the stated (or presumed) twist rate. A barrel might have 1:10″ stamped on the side but it is, in truth, a 1:10.5″ twist or even a 1:9.5″. Cut-rifled barrels, such as Kriegers and Bartleins, normally hold very true to the specified twist rate. With buttoned barrels, due to the nature of the rifling process, there’s a greater chance of a small variation in twist rate. And yes, factory barrels can be slightly out of spec as well.