|

|

January 11th, 2019

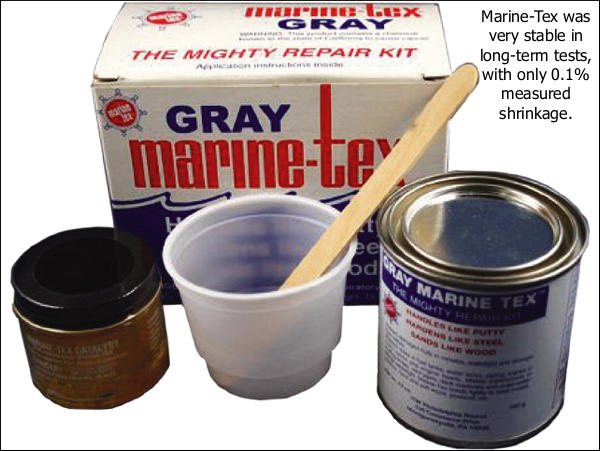

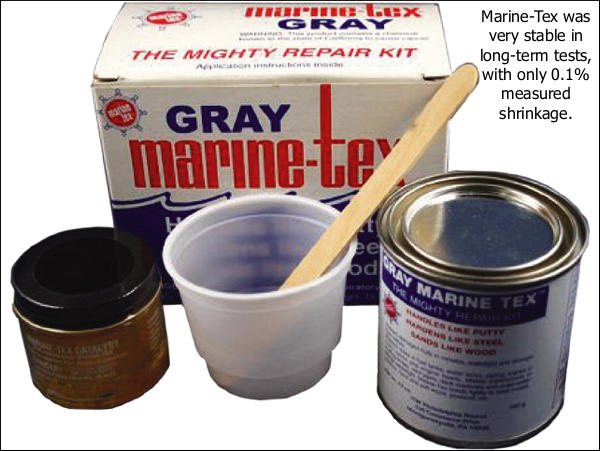

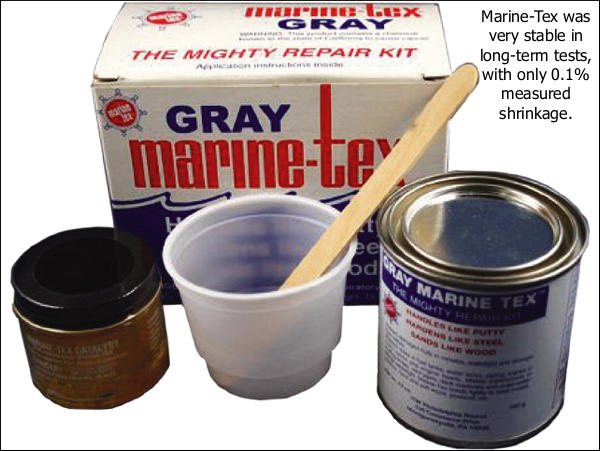

A customer of well-known gunsmith (and Hall-of-Fame shooter) Thomas “Speedy” Gonzalez recently asked Speedy about bedding compounds. Speedy offered some interesting advice based on long-term testing of various materials. Speedy favors Marine-Tex because it is very stable over time, while other materials can shrink up to 6% dimensionally. A good bedding job should be a perfect fit to your barreled action. If the bedding material shrinks over time, that is NOT a good thing….

Speedy’s customer asked: “I know you’re not a Devcon man in regards to bedding compounds but I respect your input in such matters and my question is this in regard to aluminum actions. If Devcon was considered, for an aluminum action, would you prefer aluminum compound formula or steel formula? I personally prefer Devcon steel and Marine-Tex for steel receivers but my experience with aluminum is limited. Also do you have a release agent preference that works better with aluminum?”

Speedy answered: “My only preference of one epoxy over another is their stability over time. My buddy who works for the Texas State Weights and Measures Department had me cast several of the most common types of epoxies used for bedding into 1.000″ machined blocks. After one year of being kept in a controlled climate and measured for shrinkage monthly, the Marine Tex shrunk only 1/10th of 1% (i.e. 0.1%) whereas almost all the others (including Devcon Steel formula, Devcon Aluminum formula…) shrunk 3% to 6%. The only other compounds that matched the Marine Tex were Araldite 1253 and Araldite 2014, with the latter being quite expensive for daily use.”

Speedy added: “The Marine Tex Grey has no atomized metal in its makeup even though it appears that it does. This can be proven by the use of a strong neodymium magnet. What is humorous to me is that people don’t like aluminum yet will bed their actions atop aluminum pillars that have twice the coefficient of expansion (COE) of steel. Like Devcon, it is what people have always done and used. Thus [they] perpetuate the same old stuff. That’s my two cents’ worth. But as I tell everyone, ‘I’ll tell you what I know or do, but it’s not my job to convince anyone to do it my way’.”

Release Agents — Try Shoe Polish

Regarding release agents, Speedy stated: “I use Kiwi Neutral or Tan shoe polish. This works great and you can find it anywhere. Do NOT use the black or brown as it will stick.”

View More Photos of Speedy Inletting and Bedding Job

CLICK HERE to see an interesting bedding job done by Speedy using a custom titanium bedding block. Speedy notes, “The stock was a raw blank requiring full inletting for the action to fit properly plus the titanium block. All the loading ports, bolt handle cut, bolt stop, and trigger guard cuts were done with diamond tooling to eliminate fraying and/or delamination of the wood.” You’ll find more projects by Speedy on his Facebook Page. Speedy is in San Antonio, Texas now, and accepting new projects with his company S.G. Rifles LLC.

Share the post "Bed It Right! Bedding Compounds Compared by Speedy"

November 21st, 2018

Note the owner’s name, “S. Limbourne” was engraved on the bolt release (and trigger guard, see below).

Who doesn’t like a spectacular figured-wood stock, particularly when it is combined with a superb custom action and a tack-driving barrel. Here’s some eye candy for Wednesday before Thanksgiving. This is a custom .284 Winchester F-Class Open division rig created by gunsmith Thomas “Speedy” Gonzalez for competitive shooter Scott Limbourne. The handsome Bacote wood figured stock comes from Cerus Rifleworks, while the action is a polished Borden RBRP BRMXD. Two Brux 1:9″ twist barrels were chambered for the project, both finished at 32″. The stock is also fitted with a R.A.D. Recoil System. This rig has top-of-the-line hardware all around.

Action: Borden BRMXD – Polished

Rail: 20 MOA Polished

Chambering: .284 Winchester

Trigger: Jewell BR – Blueprinted

Barrel: (2x) Brux 32″ 1:9″ Twist

Stock: Cerus F-Open in Exhibition Grade Bacote

Recoil System: R.A.D. System

Extras: Carbon Fiber Tunnel Plate, Custom Engraving Work on Action, Trigger Guard, and Bolt Release.

You’ll find more impressive rigs on Speedy’s Facebook Page. If you’d like a superb custom rifle like this, call Thomas “Speedy” Gonzalez at 972-672-6630, or send email to: speedy.godzilla [at] msn.com.

SPEEDY GONZALEZ

9023 HUEBNER RD. STE 102

SAN ANTONIO, TX 78240

Share the post "Handsome .284 Win F-Class Rig with Polished Borden Action"

November 1st, 2018

At the request of Forum members, we are reproducing this helpful article by gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez

How to Reduce Vertical in Your Shot Groups

One of our Shooter’s Forum members recently built a new benchrest rifle. He was concerned because his groups were stringing vertically. This is a common problem that all precision shooters will face sooner or later. In addition to ammo inconsistencies, many other factors can cause vertical stringing. Accordingly, it’s important that you analyze your gun handling and bench set-up systematically.

Hall of Fame benchrest Shooter Speedy Gonzalez has written a helpful article that explains how to eliminate mechanical and gun-handling problems that cause vertical spread in your groups. Speedy’s article addresses both the human and the hardware factors that cause vertical. CLICK HERE to read the full article. Here are a few of Speedy’s tips:

• Front Bag Tension — Vertical can happen if the front sand bag grips the fore-arm too tightly. If…the fore-arm feels like it is stuck in the bag, then the front bag’s grip is too tight. Your rifle should move in evenly and smoothly in the sand bags, not jerk or chatter when you pull the gun back by hand. • Front Bag Tension — Vertical can happen if the front sand bag grips the fore-arm too tightly. If…the fore-arm feels like it is stuck in the bag, then the front bag’s grip is too tight. Your rifle should move in evenly and smoothly in the sand bags, not jerk or chatter when you pull the gun back by hand.

• Sandbag Fill — A front sandbag that is too hard can induce vertical. Personally, I’ve have never had a rifle that will shoot consistently with a rock-hard front sandbag. It always causes vertical or other unexplained shots.

• Stock Recoil — Free-recoil-style shooters should be sure their rifle hits their shoulder squarely on recoil, not on the edge of their shoulder or the side of their arm. If you shoulder your gun, you need to be consistent. You can get vertical if your bench technique is not the same every shot. One common problem is putting your shoulder against the stock for one shot and not the next.

• Front Rest Wobble — You will get vertical if the top section of the front rest is loose. Unfortunately, a lot of rests have movement even when you tighten them as much as you can. This can cause unexplained shots.

• Stock Flex — Some stocks are very flexible. This can cause vertical. There are ways to stiffen stocks, but sometimes replacement is the best answer.

• Rifle Angle — If the gun is not level, but rather angles down at muzzle end, the rifle will recoil up at butt-end, causing vertical. You may need to try different rear bags to get the set-up right.

• Unbalanced Rifle — If the rifle is not balanced, it does not recoil straight, and it will jump in the bags. If the rifle is built properly this will not happen. Clay Spencer calls this “recoil balancing”, and he uses dual scales (front and rear) to ensure the rifle recoils properly.

• Firing Pin — A number of firing-pin issues can cause vertical. First, a firing pin spring that is either too weak or too strong will induce vertical problems. If you think this is the problem change springs and see what happens. Second, a firing pin that is not seated correctly in the bolt (in the cocked position) will cause poor ignition. Take the bolt out of rifle and look in the firing pin hole. If you cannot see the entire end of firing pin it has come out of the hole. Lastly, a firing pin dragging in bolt or shroud can cause vertical. Listen to the sound when you dry fire. If you don’t hear the same sound each shot, something is wrong.

• Be Consistent — You can get vertical if your bench technique is not the same every shot. One common problem is putting your shoulder against the stock for one shot and not the next.

• Head Position — Learn to keep your head down and follow-through after each shot. Stay relaxed and hold your position after breaking the shot.

• Last Shot Laziness — If the 5th shot is a regular problem, you may be guilty of what I call “wishing the last shot in”. This is a very common mistake. We just aim, pull the trigger, and do not worry about the wind flags. Note that in the photo below, the 5th shot was the highest in the group–probably because of fatigue or lack of concentration.

CLICK HERE for Speedy’s full article with more tips and advice.

Share the post "How to Tame Vertical Stringing — Tips from Speedy"

June 28th, 2018

Editor: Many new barrels will deliver higher velocities with the same load after 100-150 rounds through the bore. The exact reasons for this speed-up are not 100% certain, and velocity increases (if any) will vary from one barrel to the next. But this “speeding up” phenomenon is common, so be prepared if this happens with your next barrel. If you do experience a significant velocity increase you should probably re-tune your load AFTER the velocity stabilizes at the higher level.

From the Sierra Bullets Blog

Article by Mark Walker, Sierra New Product Development Director

In a previous post, I discussed a couple of methods to tune a load to your barrel to help achieve the best accuracy possible. People most often work on load tuning if they get a new rifle or have a different barrel installed. In both instances, the barrel is new and has not been fired very much. According to most competitive shooters, this is the most accurate your barrel will ever be, so getting it tuned and shooting accurately is a priority.

The Speed Up Phenomenon After 100-150 Rounds

Even though after you work up a load and your new barrel is shooting great, a lot of shooters notice that at around 100 to 150 rounds their rifle may stop shooting as accurately. I had this happen to a rifle and I was confused as to why something that worked so well to begin with would all of a sudden quit shooting. I decided to break out the chronograph to do another load work up to see what was going on. To my surprise, the velocity had increased around 80 fps over the original velocity! After performing another ladder test and adjusting the seating depth, the rifle was once again shooting well.

There are several thoughts on why this may happen, however, you can rest assured that it does happen. One thought is that as the barrel breaks in, the tooling marks in the throat of the chamber smooth out and allow less resistance to the bullet as it exits the bore thereby increasing speed. Another idea is that the throat area starts to get a little rough which in turn causes more resistance which increases pressure and therefore more velocity. I’m sure there are some out there who have a better understanding as to why this happens, but it can definitely affect the accuracy of your rifle. So be aware and never be afraid to rework a load to keep your rifle in tune.

Experts Confirm That Barrel Speed-Up Is Common

Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds. Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds.

“Alex Lipworth and I documented this phenomenon about four years ago and I have told all my customers about this. My son Mikee would shoot 100 rounds through all new barrels we planned on shooting before we would begin to do load development. We had a shooting snail that caught all the bullets set up in front of an indoor bench. We called it a wear-in process because upon careful examination of the bore when the ‘Speed Up’ takes place the cut-rifled bore resembles that more of a button-rifled barrels with the lands taking on more the softer look of a buttoned bore.” — Speedy Gonzalez

“Seen it [barrel velocity increase] too many times to count. All my match barrels get a ‘generic round’ loaded for them, which has worked well in barrels historically. After I hit 150 rounds I fine-tune the load and never look back, until the tube starts to slow down at it’s life end.” — Jim See

Share the post "TECH TIP: Velocity Increase In New Gun Barrels"

May 8th, 2018

LabRadar owners can celebrate. New mobile-friendly control software is coming soon. Gunsmith and Benchrest Hall of Famer Thomas “Speedy” Gonzalez had some interesting news from the NRA Show in Dallas. He learned that the creators of the LabRadar chronograph systems will soon offer Mobile Apps that can run on your iOS or Android smartphone or tablet. This new software will make it much easier to control the LabRadar, and offer enhanced data editing functionality.

New LabRadar iOS and Android Mobile Apps Coming Soon…

Speedy says: “I just got back from the NRA show in Dallas, Texas. The coolest thing I personally saw at the show was at the LabRadar booth. They had the Beta versions of their new LabRadar Apps for the iPhone and Android phones. These Apps let you control all LabRadar functions from your phone as well as your tablet via Bluetooth connection. The new Apps will also allow the LabRadar owner to store and edit his or her data from a much larger and user friendly screen.” Speedy says: “I just got back from the NRA show in Dallas, Texas. The coolest thing I personally saw at the show was at the LabRadar booth. They had the Beta versions of their new LabRadar Apps for the iPhone and Android phones. These Apps let you control all LabRadar functions from your phone as well as your tablet via Bluetooth connection. The new Apps will also allow the LabRadar owner to store and edit his or her data from a much larger and user friendly screen.”

That’s good news. We particularly like the ability to edit LabRadar data on a tablet. Speedy added: “This is going to revolutionize this great product and make it [much more] user-friendly.”

The new LabRadar Mobile Apps will be available free for LabRadar owners. If you own a LabRadar, be sure to register your LabRadar on the LabRadar Website. That will ensure you are notified via email as soon as the software is available. To register, look for the text link at the top right of the LabRadar homepage. It says “Register your LabRadar “. Click the link then fill out the data form.

Share the post "New Mobile Apps for LabRadar to Be Released Soon"

March 8th, 2018

This barrel’s shoulder was 0.025″ off the action because Red Locktite had been used on the threads.

Gunsmith Thomas ‘Speedy’ Gonzales offered this interesting report about how NOT to headspace a barrel. Hopefully you never discover something like this…

“A good friend and customer sent this rig in for repair after FedEx damaged the rifle during inbound transport from another smith. After repairing the stock and rebedding it, I decided to re-polish the barrel to make the repair perfect. Well this just added insult to injury as the barrel did not want to come off. After a few choice words, the barrel finally broke free only to reveal something very disturbing. It seems the barrel had been ‘headspaced’ by using RED Loctite to hold it in place.” [Editor: That’s definitely NOT how barrels should be fitted.]

Speedy was not happy: “I hope the smith that did this sees the photos and realized what jeopardy he put my customer in or anyone who shot the rifle for that matter. When cleaned up, the shoulder on the barrel was over 0.0250″ (25 thousandths) away from the face of the receiver.” [Editor: That’s a lot in this business]. Check out the images below to see how much the barrel rotated further inward when cleaned up. The barrel spun in nearly another eighth-turn or more. Not good.

Share the post "How NOT to Headspace a Barrel — Speedy’s Disturbing Discovery"

July 11th, 2017

That fancy front rest is a Farley with custom polished aluminum magnum base, John Loh top, and upgraded large-diameter “Speed Demon Wheel” elevation adjustment. The barrel is a 1:8.75″-twist Bartlein fitted with Ralph Stewart 3-Disk rotary tuner. The 32″-long tube tapers from 1.250″ to 1.0″ diameter. Speedy prefers to have a bit of taper in barrels even when weight is not a factor.

The F-Class World Championships take place next month at the Connaught Ranges in Ontario, Canada. Here’s something special gunsmith Speedy Gonzales put together for F-Open shooter Brett Solomon. Christened the “Little Red Devil” by Speedy, this ruby red, flame maple-stocked beauty is chambered in .284 Winchester. It features a Melonited BAT 3LL action with two bolts (regular and magnum bolt face). The stock is the Speedy “Spear of Destiny” design crafted by Will McCloskey. These handsome McCloskey stocks are milled with advanced CNC machines, allowing ultra-precise tolerances for improved tracking and perfect geometry.

Speedy tell us: “Wish I could say the pictures do it justice. It is ten times nicer looking in real life. Bret will be rubbing on it for hours when it arrives…”

Torrefied Wood from Yamaha

This wood is very special — the flame maple was sourced from Yamaha which used a torrefaction process to stabilize the wood and prevent warping. Yamaha’s proprietary ARE process was developed by Yamaha for musical instruments. Speedy explained that Yamaha uses heat and pressure (we think) to stabilize the wood and dampen vibrations. During torrefaction, the sap in the wood actually crystallizes.

For this rifle build, the torrefied wood blank was CNC-milled by Will McCloskey to “best-in-industry” tolerances. Then Speedy did the inletting, fit the triggerguard, action pillars, butt-plate assembly, and other details. Then Speedy removed the metal parts and shipped the stock to Lee Garver, a noted guitar painter. Garver applied a special red-tone polyester finish. This is a very hard, yet glossy finish that makes the stock “pretty nearly scratch-proof” according to Speedy.

The rifle sports one of Ken Rucker’s new F-Class Bump-Buster Gold recoil reducers. This new system is optimized for prone shooting and works with minimal touch/hold shooting styles.

This video shows the CNC-Milling process with another Speedy stock, the adjustable-comb version of his “Spear of Destiny” design:

The BAT 3LL action comes with two (2) complete bolts, one with standard bolt face, the other with a magnum bolt face.

When One Stunning Rifle Is Not Enough…

If you aren’t yet totally consumed with envy, consider this. Brett Solomon has invested in THREE more Speedy-built rifles like this red wonder. There’s a TAN (natural finish) rimfire training rig that’s complete, and Speedy’s now working on a GREEN .284 Win “spare”, plus a BLUE dedicated Magnum rig. The tan, green, and blue rigs for Brett will have similar stocks, with “all the bells and whistles” just like the “Little Red Devil”. Brett is currently using the tan-stocked rimfire rig for training — getting lots of “trigger time” without burning out his precious centerfire match barrels.

Share the post "“Little Red Devil” for the F-Class World Championships"

March 11th, 2017

Ed Connors placed three consecutive shots all on target at 2160 yards for a sub-3/8 MOA group. Wow.

Amazing shooting — that’s how we’d describe what Ed Connors accomplished recently with his Speedy-built .338 Lapua Magnum LR rifle. Ed nailed a 3-shot group at 2160 yards that would be great at 1000 yards. Check out the target above. Now consider that the shooter was a full mile PLUS 400 yards away. That is truly remarkable accuracy.

At this distance, 2160 yards, one MOA is 22.61″. This three-consecutive-shot group, measuring about 8 inches, works out to less than 3/8 MOA. Think about that — most guys would be elated to shoot 3/8 MOA at two hundred yards. Ed did that at over two thousand yards!

That takes a great rifle, as well as great ammo. Ed says: “I believe in loading like a benchrest shooter to achieve these ultra long-range shots”.

|

Rifle Specifications:

– .338 LM Rifle built by SG Rifles, LLC

– Surgeon Rifles Action (blueprinted by Speedy)

– Jewell Trigger (blueprinted by Speedy)

– McMillan Fiberglass Stock

– Nightforce 5-25x56mm ATACR Scope

– Bartlein 1:9″-twist 32″ Barrel, Speedy contour

– Amer. Prec. Arms “Fat Bastard” Muzzle Brake |

Ammunition Specifications:

– Lapua .338 LM Brass turned with Nielsen “Pumpkin” turner.

– Hodgdon H1000 Powder, 90.8 Grains

– Remington 9 1/2 Magnum Primers

– Berger .338 Cal 300 grain Hybrid OTM Tactical Bullets seated .005″ off lands.

– Velocity: 2875 fps / SD 5.0 |

Gunsmith Thomas “Speedy” Gonzalez writes: “Anytime you build a customer a rifle to work out beyond the 1000-yard mark you must work hand-in-hand with your customer and explain everything you are doing to ensure performance at distances most shooters never even contemplate (except in their dreams).

Ed was involved in all aspects of the projects from the reamer print to what we needed for both single-shot work and mag-fed function in timed competition. This was Ed’s very first work-out with his reborn Surgeon-actioned .338 Lapua Magnum. He did great to say the least!”

Pretty Darn Good at One Mile as Well…

While “tuning up” for his 2160-yard session. Ed also produced some very impressive results at one mile (1760 yards). Once he got “dialed in” he delivered three shots you can cover with the palm of your hand. That’s spectacular consistency at one mile.

Share the post "Extreme Long Range — .338 Lapua Magnum at 2160 Yards"

January 15th, 2017

A customer of well-known gunsmith (and Hall-of-Fame shooter) Thomas “Speedy” Gonzalez recently asked Speedy about bedding compounds. Speedy offered some interesting advice based on long-term testing of various materials. Speedy favors Marine-Tex because it is very stable over time, while other materials can shrink up to 6% dimensionally. A good bedding job should be a perfect fit to your barreled action. If the bedding material shrinks over time, that is NOT a good thing….

Speedy’s customer asked: “I know you’re not a Devcon man in regards to bedding compounds but I respect your input in such matters and my question is this in regard to aluminum actions. If Devcon was considered, for an aluminum action, would you prefer aluminum compound formula or steel formula? I personally prefer Devcon steel and Marine-Tex for steel receivers but my experience with aluminum is limited. Also do you have a release agent preference that works better with aluminum?”

Speedy answered: “My only preference of one epoxy over another is their stability over time. My buddy who works for the Texas State Weights and Measures Department had me cast several of the most common types of epoxies used for bedding into 1.000″ machined blocks. After one year of being kept in a controlled climate and measured for shrinkage monthly, the Marine Tex shrunk only 1/10th of 1% (i.e. 0.1%) whereas almost all the others (including Devcon Steel formula, Devcon Aluminum formula…) shrunk 3% to 6%. The only other compounds that matched the Marine Tex were Araldite 1253 and Araldite 2014, with the latter being quite expensive for daily use.”

Speedy added: “The Marine Tex Grey has no atomized metal in its makeup even though it appears that it does. This can be proven by the use of a strong neodymium magnet. What is humorous to me is that people don’t like aluminum yet will bed their actions atop aluminum pillars that have twice the coefficient of expansion (COE) of steel. Like Devcon, it is what people have always done and used. Thus [they] perpetuate the same old stuff. That’s my two cents’ worth. But as I tell everyone, ‘I’ll tell you what I know or do, but it’s not my job to convince anyone to do it my way’.”

Release Agents — Try Shoe Polish

Regarding release agents, Speedy stated: “I use Kiwi Neutral or Tan shoe polish. This works great and you can find it anywhere. Do NOT use the black or brown as it will stick.”

View More Photos of Speedy Inletting and Bedding Job

CLICK HERE to see an interesting bedding job done by Speedy using a custom titanium bedding block. Speedy notes, “The stock was a raw blank requiring full inletting for the action to fit properly plus the titanium block. All the loading ports, bolt handle cut, bolt stop, and trigger guard cuts were done with diamond tooling to eliminate fraying and/or delamination of the wood.” You’ll find more projects by Speedy on his Facebook Page. Speedy is in San Antonio, Texas now, and accepting new projects with his company S.G. Rifles LLC.

Share the post "What Are the Best Bedding Materials? Speedy Speaks"

April 9th, 2016

Over the years, noted gunsmith and a Benchrest Hall-of-Fame inductee Thomas ‘Speedy’ Gonzalez has learned a few things about “tuning” rear sandbags for best performance. On his Facebook page, Speedy recently discussed how sand bag fill levels (hard vs. soft) can affect accuracy. Speedy says you don’t want to have both your front and rear sandbags filled up ultra-hard. One or the other bag needs to have some “give” to provide a shock-absorbing function (and prevent stock jump).

SAND BAGS & HOW TO FILL THEM by Speedy Gonzalez

I was asked several times by competitors at the S.O.A. Matches and F-Class Nationals as to how I fill my sand bags for benchrest competition. Here is a copy of a reply I gave several years ago:

Back in the old days, about the time Fred Flintstone was still alive, I worked for Pat McMillan for free, from time to time to learn all his secrets. One day little Speedy was filling some new sand bags out behind Pat’s shop, stuffing them with more sand than Taco Bell put beans in their Burritos. When Pat stepped out the back door and inquired as to what in the hell was I doing packing them there bags the way I was. Back in the old days, about the time Fred Flintstone was still alive, I worked for Pat McMillan for free, from time to time to learn all his secrets. One day little Speedy was filling some new sand bags out behind Pat’s shop, stuffing them with more sand than Taco Bell put beans in their Burritos. When Pat stepped out the back door and inquired as to what in the hell was I doing packing them there bags the way I was.

I looked up at him with eyes like a kid with his hands in a cookie jar. My reply must have sounded like Homer Simpson “Doooh”. Finally I said “I don’t know, Boss. I just thought you were supposed to fill these babies up and go shoot. I got that ‘You dumb bastard look’ from Pat and I knew it was lecture time. This was what he told me:

You can not have two bags filled so hard that you gun bounces on them in the process of firing round at your target, especially if you have a rig with a very flexible stock. The bags must be set up in a manner for them to absorb the initial shock of the firing pin moving forward and igniting the primer. Then [they must] maintain their shape and absorb the second shock wave as well the rearward thrust and torque of the rifle. What happens to the rifle when this is not done? Well let me tell you. The rifles have a very bad tendency to jump and roll in the bags. This causes many of those wild, lost shots that one can’t explain.

Charles Huckaba, Ken Terrell, Larry Baggett, Ralph Stewart and some of us Texas shooters talk about this phenomena quite often. We have all agreed that:

- 1: You can not have two hard bags [i.e. both front AND rear] in your set-up.

- 2: Heavy sand magnifies these phenomena.

- 3: If you are a bag squeezer, pack ears hard and leave bag pliable enough to squeeze for the movement required. You may pack front bag as hard as rules permit.

- 4: Free recoil shooters pack both bags firm, but not so hard as to allow stock jump. Especially if you have a stock with a very flexible forearm.

- 5: We use play-ground sand, also know as silica sand. I sift mine to get any large impurities out then mix it with 25% to 50% with Harts parakeet gravel to the desired hardness that I am looking for. The bird gravel keeps the sand from packing itself into that solid as a brick state.

Speaking of bricks — another thing that happens when shooters employ that heavy zircon sand is the ears form a low spot under them from recoil and then tend to rock back and forth with the rifle causing many low shots to crop up. Edgewood makes an Edgewood/Speedy rear bag specially reinforced under the ears to eliminate this scenario.

One last note –If you use the Cordura bags keep them sprayed with a good silicon spray or “Rain-Ex”. This keeps them from getting sticky. Hey guys, try that and see if it helps. — Speedy

P.S.: I do not like the solid double-stitched leather bottoms. While this seems like a good idea, I see more shooters have problems because of them. They tend to slide around the bench and or slide with the rifle on recoil. The standard Protektor with Cordura rabbit ears and an Otto ring bag with a Cordura front would be what I would suggest to the new shooter or one of the Edgewood / Speedy rear bags, these mimic the “Donut” and feature a ring of leather around the bottom circumference that keep the bottom from rocking on the bench or ground if that is where you reside these days…

Share the post "Tuning Your Sandbag Hardness — Tech Tip by Speedy"

November 6th, 2015

Benchrest Hall-of-Famer Thomas “Speedy” Gonzalez has teamed up with the Shurley Brothers on a new ARK series of wood laminate competition stocks. Speedy has combined the best features of various popular F-Class and Long-range Benchrest stocks into new designs to be produced by Shurley Brothers Custom in Austin, Texas. These stocks should be very straight and geometrically correct as they will be crafted on the Shurley Brothers’ new CNC mills. These stocks will be made with new-generation precision technology, not old school duplicating machines.

Initially two models will be offered: the “Hand of God” (HOG) and the “Spear of Destiny” (SOD). Both are designed for multiple shooting disciplines, so they should work well both for benchrest and for prone F-Open shooting. (FWIW, John Myers used a Speedy-crafted stock to win the 2015 Mid-Range National Championship). The forearm is 76mm (2.99″) to comply with F-Open limits. A wide variety of options will be available including adjustable Cheek Piece, adjustable length of pull, carbon fiber inserts, and exotic woods.

We like many aspects of the new stocks. First, the front of the stock is low profile, placing the barrel close to the bags for better tracking (and less hop). However, a deeper (top to bottom) section extends forward of the action — this is important. We have seen some low-profile stocks that suffer from forearm flex/hinging because they don’t leave enough wood under the action area. Speedy’s design eliminates this problem. Another nice feature of this stock is the subtle curve from the back of the action to the buttpad mount. Speedy calls this the “scooped cheek”. This allows the “driver” to shoot without face contact if he prefers, but it also allows for a higher buttpad position — which is useful when shooting heavy recoiling chamberings such as the .300 WSM.

Note how the comb area has a curve to provide clearance. For those shooters who prefer to have face contact on the gun, an adjustable Cheek Piece is offered.

Shurley Brothers Custom says these new ARK stocks are fully customizable for competition shooters with optional carbon fiber, adjustable R.A.D. systems, and many other features. The stocks, uninletted, will run $750.00. CNC-inletting (for action of your choice) is an additional $100.00. Here are some of the many available options:

— Pillar Bed and Inlet: $425.00

— Custom Wood Upgrade (Price Dependent On Wood): $100.00 – $500.00

— Full-length Carbon Fiber Stringers: $200.00

— Cheek Piece Addition: $100.00

— Cooling Ports (Buick Vents): $60.00

— R.A.D. System #2A: $335.00 (plus $100.00 to install)

— 3-Way Butt Plate: Call for Price

— Adjustable Neodymium Magnetic Cheek Piece: Call for Price

— Install Neodymium Magnetic Cheek Piece: $150.00

— Stock Finish & Clear Coat: $350.00

— Carbon Fiber Forearm Tunnel: $300.00

The underside of the forearm is relieved in the center, leaving twin outboard rails. This helps stabilize the rifle and aids tracking. (A conventional, flat forearm without rails tends to rock if there is any hump in the middle of the sandbag). Between the rails is a carbon-fiber stiffening insert.

Share the post "New Speedy-Designed Competition Stocks from Shurley Brothers"

August 20th, 2014

Is your mirage band really “the best it can be”? Or is it actually allowing warm air to flow in front of your scope, causing mirage? Here’s an interesting graphic that suggests that the size, shape, and curvature of a mirage shield can make a difference. We can’t say this diagram is based on exhaustive scientific testing (and we think the flow patterns are exaggerated for effect), but it does illustrate how airflow can be altered by shield shape.

This graphic comes from Fierce Vinyl a company that produces high-quality aluminum mirage shields for shooters. Fierce Vinyl is run by the daughter of ace gunsmith (and Hall of Fame shooter) Thomas ‘Speedy’ Gonzalez. Fierce Vinyl sells custom 26″ aluminum mirage shields (with graphic imprint) for $21.99 + shipping. That price includes printing the graphic on the shield, if you provide the artwork. Inquire about custom art designs or large orders.

Along with Mirage Bands, Fierce Vinyl produces a variety of graphic products, labels, and stickers. If you need a placard, graphic, or bumper sticker for your business or shooting range, Fierce Vinyl can help you out. See more product designs on the Fierce Vinyl Facebook Page.

Share the post "Tech Tip: Mirage Shields — They Aren’t All the Same"

|

• Front Bag Tension — Vertical can happen if the front sand bag grips the fore-arm too tightly. If…the fore-arm feels like it is stuck in the bag, then the front bag’s grip is too tight. Your rifle should move in evenly and smoothly in the sand bags, not jerk or chatter when you pull the gun back by hand.

• Front Bag Tension — Vertical can happen if the front sand bag grips the fore-arm too tightly. If…the fore-arm feels like it is stuck in the bag, then the front bag’s grip is too tight. Your rifle should move in evenly and smoothly in the sand bags, not jerk or chatter when you pull the gun back by hand.

Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds.

Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds.

Speedy says: “I just got back from the NRA show in Dallas, Texas. The coolest thing I personally saw at the show was at the LabRadar booth. They had the Beta versions of their new LabRadar Apps for the iPhone and Android phones. These Apps let you control all LabRadar functions from your phone as well as your tablet via Bluetooth connection. The new Apps will also allow the LabRadar owner to store and edit his or her data from a much larger and user friendly screen.”

Speedy says: “I just got back from the NRA show in Dallas, Texas. The coolest thing I personally saw at the show was at the LabRadar booth. They had the Beta versions of their new LabRadar Apps for the iPhone and Android phones. These Apps let you control all LabRadar functions from your phone as well as your tablet via Bluetooth connection. The new Apps will also allow the LabRadar owner to store and edit his or her data from a much larger and user friendly screen.”