Free Reloading Bench Plans

Serious shooters spend lots of time in the reloading room. If you want to produce great ammo, start with a good, solid bench with a very rigid working surface and plenty of storage space. Here we present three sets of FREE workbench plans. Any one of these bench designs can be a good winter do-it-yourself project for those with basic word-working skills.

Easy-to-Build Basic Bench

Simpson, maker of Strong-Tie fasteners, offers FREE Workbench Plans for a sturdy, 48″-wide bench with a pegboard backing and both upper and lower shelves. A complete list of fasteners and cut lengths is provided. For use as a loading bench with mounted presses, double-up the bench-top for extra ridigity. Without much difficulty, the plans can be adapted to build a wider bench if you prefer. The same downloadable document also contains plans for an 80″-high 6-shelf unit, a 72″-high heavy-duty shelving unit (with 4 shelves), and a 48″-wide heavy-duty table.

FREE Strongtie Bench Plans (.pdf file).

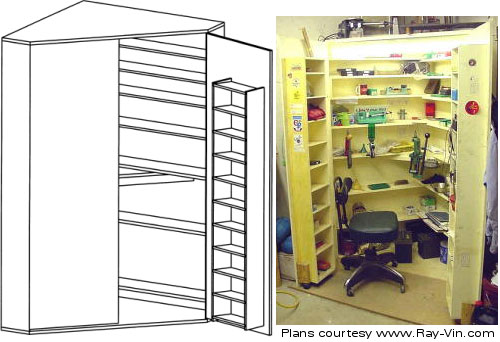

Corner Bench with Swinging Doors

The next design is rather unique — a corner bench with swing-out cabinets. This reloading bench is based on plans by M. L. McPherson as published in the October 1993 American Rifleman. The compact footprint that makes good use of corner space that is usually poorly utilized. This set of plans is provided by from Ray-Vin.com, which sells scope stands, shooting carts, sight accessories, and AR15 parts.

FREE Corner Bench Plans (330kb .pdf file)

Classic NRMA Bench with Cabinets

The last bench design is a large, versatile bench with a full set of enclosed overhead cabinets. A National Reloding Manufacturers Association (NRMA) design, this bench requires many hours to build, but it will house all your reloading gear and provide a very stable platform for your presses.This bench was designed to be as versatile as possible to meet the needs of most reloaders. However, the bench design can easily be customized. For instance, it can be made larger or smaller to meet space requirements or quantities of equipment and components. As it is currently designed, the work area is about waist-high for a 6’2″ person. This can be adjusted to fit your height simply by making the legs longer or shorter.

FREE NRMA Reloading Bench Plans (2.42 megabyte .pdf file).

Similar Posts:

- BYOB — Build Your Own Bench with Free Plans

- Build Your Own Reloading Bench with FREE Plans

- FREE Heavy-Duty Workbench Plans

- Build Your Own Workbench–Free Plans

- FREE Plans for Heavy-Duty Workbench

Tags: Bench, Wood Working

I built one of these 15 yrs ago and I can tell you that you will never be sorry that you built the best. It takes a couple days to build but mine has at least another 50 years of good use and you will never worry about it being strong enough to hold any amount of weight or handle any press. The only problem is buying enough STUFF to fill all the space. I have been trying for 15 years and I think its about 3/4 full. If you want to reload a LOT this is the one to bulid.

I commissioned a carpenter to build the NRMA bench. It’s good to hear that it’s a good bench, not that I would really know as it’ll be my first bench. It gets delivered today. I’ll let the forum know how it works out.

I bought an RCBS 2000 and will reload .300WinMag, .45acp, 9mm, .44Mag, .270 rounds. I have never reloaded before but my kids are driving me into the poor house with all the ammo they’re going through. Reloading is a financially defensive move on my part. I have an enthusiatic neighbor who is willing to teach me the rudiments.

These plans look great just what i will need.Because right now every thjng is kind of cramped.

I just want you to know that i am greatly appreciative and i have enjoyed your websight,for

some time.

sincerly Russell Hayes

Hello Steve……….Please tell me how your NRMA reloading bench worked out. Was it everything you had hoped for? I’m in the process of getting equipment organized to begin a part-time reloading business and a good quality reloading bench is needed. The NRMA bench looks like it could be what I need, but it is always useful to get the opinion of someone that already has and is using the product. Looking forward to your response, so I can proceed accordingly. Thanks…….Regards…….Paul

I built the NRMA reloading bench about 8 years ago. A friend with a table saw helped me do it. The whole process took about 6 weeks, working 2-3 hours, 3 days a week. Mine is first rate with red fir 4×4 and birch plywood. The tops and shelves are golden oak with a walnut stain on the sides and 4x4s…5 coats of polyethelene and we finished the cut edges of the plywood with stips of fir laminate and finishing nails. I used 1/4″ fiberboard to back the shelves. It is a piece of furniture! I’ve mounted 2 presses on it and it contains dies and bullets for about 15 different calibers. Nice! I put some high quality materials into the project and the cost was a tad over $400. You can build a functional bench with lower cost materials for less than half that but it won’t be as pretty as mine. I drilled holes for shelf holders so that they can be configured for just about any size…I may later install some drawer bins in the lower shelf later to organize brass casings and whatnot but it’s very nice as is!

I have had two of the NMRA benches built.(1975,1983) Sold the first after moving to an apartment, and built the second after getting into my own home. This is a solid bench, with ample storage (unless you are a hopeless hoarder like myself I reload for about 20 calibre’s so storage had to be expanded, with metal shelving. I would like to change the method for mounting presses, as my top is starting to look more like a giant pegboard, (rock chucker, Bonanza Co-Ax, Bair C, PW 375C, PW800C,

I reload for about 20 calibre’s so storage had to be expanded, with metal shelving. I would like to change the method for mounting presses, as my top is starting to look more like a giant pegboard, (rock chucker, Bonanza Co-Ax, Bair C, PW 375C, PW800C,

Dillon 550B, RCBS sizer, Forster case trimmer, etc) so I am considering a new top, with “dovetail” mounting panels, to put an end to the hole drilling.

I would also like to put my drawers on full length roller bearing slides, as the “stock” drawers are hard to pull out, when full (And they are full!)

Just a few thoughts for those who are building their first, or building a new “addition” to their loading room.

On the NMRA bench, is the 2×6 overhang necessary? Is seems like, if I frame the top with 2x4s, then place a piece of 3/4 in plywood over the top, that would work. Do I need that 2×6 there at all?

i built two!

one for reloading

the ledge in front is perfect for the press.

the other for everything else

thank you

thank you !

dr joe /aka bourbon doc