Problems with “Do-It-Yourself” AR-15s

Commentary by Robert Whitley

In recent years several major firearms component suppliers have promoted the idea of the “do-it-yourself” AR-15 build up. In one sense this is a good thing because it promotes peoples’ education and understanding of firearms, but the down side of this is some folks are assembling and modifying AR-15s without an understanding of the rifle and without the necessary skills and tools to do things properly. The net result of this “do-it-yourself” work can be an AR-15 that is non-functional, problematic or dangerous. Here are two examples of common issues with “do-it-yourself” modifications.

Opening Up the Ejection Port

One common modification for AR-15’s is the opening up of the ejection port. This is typically done to permit more room for ejection or loading of the rifle, and it is also typically done in conjunction with a side charging handle modification.

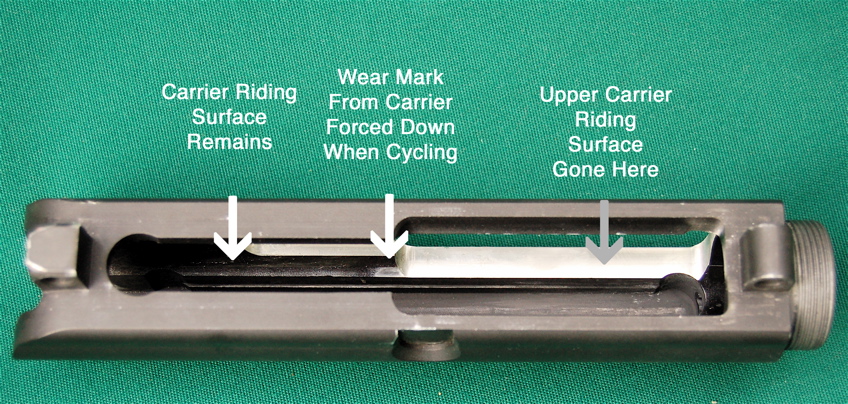

A common issue I have seen with this modification is that the person opening up the port removes the upper right hand carrier support and riding surface. The net result of this is that the carrier sits loose in the upper receiver when the bolt is in lock-up and this can have very detrimental effects on the function and accuracy of the AR-15. Below are more pictures of one that I saw recently.

Click Arrows to See all FOUR Pictures

Wrong Buffer Installed

Another common mistake is the use of an improper buffer with the rifle (i.e. like using a carbine buffer in a standard rifle length buffer tube). There are many after market buffers being sold out there, but if the wrong buffer is used with the rifle, it can allow the bolt carrier to cycle too far back so that the rear of the carrier gas key becomes the stop for the carrier (i.e. when it smashes into the upper part of the lower receiver – OUCH!).

We have even seen situations where the gas key is snapped right off the carrier from this, and it completely disables the rifle and can also cause extensive damage to the firearm as well. Unfortunately we have seen this situation far too often and it is clear that a person needs to fully understand how the buffer assembly works if “do-it-yourself” work is going to be done to the buffer assembly, since everything done to the buffer assembly has an effect on the rifle, its function and accuracy.

While I applaud the person who is self-reliant and has a “can do” attitude, the other side of this is when it comes to a firearm, “do-it-yourself” work should only be done when and if one fully understands the rifle and how it functions and how the work will affect the rifle.

Robert Whitley

AR-X Enterprises, LLC

199 North Broad Street

Doylestown, PA 18901

(215) 348-8789

www.6mmAR.com

Robert, the picture shows a non-standard aftermarket carbine buffer not a standard carbine buffer,

BD

Hi Robert,

What book (s)would you recommend to read before somebody starts a DIY AR project ?

Thanks

Upper modified by Red Jacket?

If you are doing billet uppers and lowers let the pros do it like Robert or JP, for the standard mill-spec it’s almost as cheap now to just buy them assembled, for books look at those offered on midway usa or brownells.

also let the builder know if you are ordering an upper if your previous gun is a carbine or rifle, the pictures show the difference in length, plus this will let them determine the proper gas block. bottom line don’t do any of your own machine work, and get the right parts for the right application.

also ar-15.com has some good information in it’s armory section.