Barrel Stub Gauges — Handy for Many Reloading Tasks

Next time you have a barrel fitted, consider having your gunsmith create a “stub gauge” from a left-over piece of barrel steel (ideally taken from your new barrel blank). The outside diameter isn’t important — the key thing is that the stub gauge is created with the same reamer used to chamber your current barrel, and the stub must have the same bore diameter, with the same land/groove configuration, as the barrel on your rifle. When properly made, a stub gauge gives you an accurate three-dimensional model of the upper section of your chamber and throat. This comes in handy when you need to bump your case shoulders. Just slide a fired case (with spent primer removed) in the stub gauge and measure from base of case to the end of the gauge. Then, after bumping, re-measure to confirm how much you’ve moved the shoulder.

In addition, the stub gauge lets you measure the original length to lands and freebore when your barrel was new. This gives you a baseline to accurately assess how far your throat erodes with use. Of course, as the throat wears, to get true length-to-lands dimension, you need take your measurement using your actual barrel. The barrel stub gauge helps you set the initial bullet seating depth. Seating depth is then adjusted accordingly, based on observed throat erosion, or your preferred seating depth.

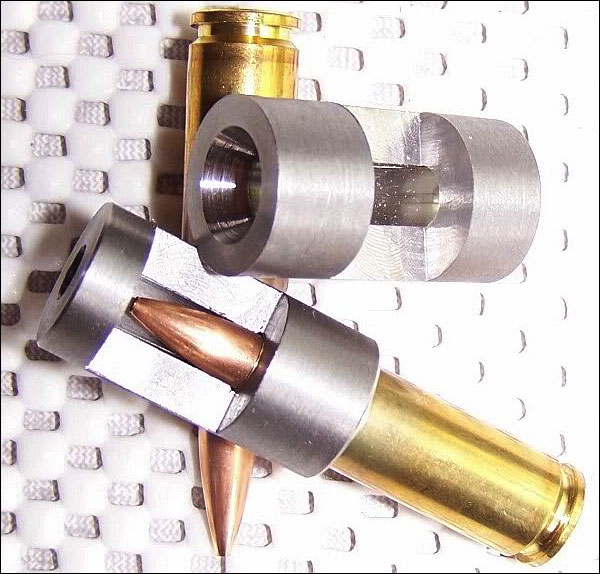

Forum member RussT explains: “My gunsmith [makes a stub gauge] for me on every barrel now. I order a barrel an inch longer and that gives him enough material when he cuts off the end to give me a nice case gauge. Though I don’t have him cut that nice-looking window in the side (as shown in photos). That’s a neat option. You can tell how much throat erosion you are getting from when it was new as well. For measuring initial seating depths, this is the most useful item on my loading bench next to calipers. Everyone should have a case gauge made by there smith if you have a new barrel put on.”

Forum member Lawrence H. has stub gauges made with his chamber reamers for each new barrel. He has his smith cut a port in the stub steel so Lawrence can actually see how the bullet engages the rifling in a newly-cut chamber. With this “view port”, one can also see how the case-neck fits in the chamber. Lawrence tells us: “My stub gauges are made from my barrels and cut with my chamber reamers. With them I can measure where my bullets are ‘touching the lands’ and shoulder bump dimensions. This is a very simple tool that provides accurate information.” To learn more about stub gauges, read this Forum Thread. The photos above and below show Lawrence’s stub gauges:

Similar Posts:

- Got Stub? Barrel Stub Gauges Serve Many Functions

- Stub Gauges — Cool Tools That Perform Important Functions

- The Stub Gauge — Why You Should Have this Handy Tool

- Use Stub Gauge to Check Shoulder Bump, Monitor Throat Erosion

- Stub Gauge — Use to Set Shoulder Bump & Check Throat Erosion

Tags: Chamber, Freebore, Gunsmith, Headspace, Reamer, Stub Gauge, Throat

This is something I have done for years now, it is one of the greatest tools in my tool box.

Nice tool, but only works if you have a reamer with the correct free-bore on it. I throat ream pretty much all my barrels to the bullet to where I want it and have short- or no free-bore reamers. Still do-able, but a little more work.

I had one for my 6PPC and used it to see if all my rounds would load before going to a match (cq tight neck turn).

Respectfully, the tool pictured is too much of a good thing. I ask the gunsmith to make a tool with the chamber reamer that starts at the shoulder-body junction, and stops at the forward end of the parallel portion of the neck. There you have a tight neck GO gage (Dasher’s comment), something to measure case headspace and max neck length. Rifling is only useful until erosion happens. You’re better off using a Hornady (formerly Stoney Point) bullet seating gage so you can maintain a consistent bullet jump over time.

Editor: Kent, if the stub gauge is made correctly, it will be a very, very close match to your original chamber. That way it gives you a “day 1″ baseline measurement, which provides a useful comparison with the throat length in the actual barrel, which, as you note, will erode over time.