Go with the “O” — O-Rings May Reduce Run-Out When Sizing

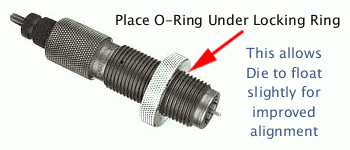

Here’s an inexpensive procedure that can help you load straighter ammo, with slightly better measured concentricity (i.e. less run-out) on the case necks and bullets. Simply use a Rubber O-Ring on the underside of the die locking ring. This allows the die to self-align itself (slightly) to the case that is being sized. Without the O-Ring, if the flat surface on the top of your press is not perfectly square with the thread axis, your die can end up slightly off-angle. This happens when the bottom of the locking ring butts up tight against the top of the press. The O-Ring allows the die to float slightly, and that may, in turn, reduce the amount of run-out induced during case sizing.

Top prone shooter GSArizona has tried this trick and he says it works: “Go to your local hardware store and get a #17 O-Ring (that’s the designation at Ace Hardware, don’t know if its universal). Slip the O-Ring on the die and re-adjust the lock ring so that the O-Ring is slightly compressed when the die is at the correct height. Size and measure a few more cases. You will probably see a slight improvement in neck concentricity as the die can now float a bit as the case enters and leaves it. This isn’t going to be a dramatic improvement, but it’s a positive one.”

We want to stress that adding O-Rings to sizing dies may help some reloaders, but we don’t offer this as a panacea. Try it — if using the O-Ring reduces measured runout that’s great. If it doesn’t, you’ve only spent a few pennies to experiment.

Lee Precision makes die lock rings with built-in O-Rings. Lee’s distinctive lock ring design allows the same kind of self-alignment, which is good. However, Lee lock rings don’t clamp in place on the die threads, so they can move when you insert or remove the dies — and that can throw off your die setting slightly. By using an O-Ring under a conventional die lock ring (that can be locked in place), you get the advantages of the Lee design, without the risk of the lock ring moving.

Similar Posts:

- O-Rings on Sizing Die Lock Rings Can Reduce Run-out

- Try Using O-Rings with Sizing Dies for Reduced Neck Run-out

- Reloading TIP — O-Rings Can Help Reduce Run-out When Sizing

- TECH TIP: Use Rubber O-Rings with Sizing Dies for Less Run-Out

- Better Locking Rings for Your Dies

Tags: Concentricity, FL Sizing, Lee Precision, O-Ring, Reloading, Run-Out, Sizing Die

I read an article on this twenty five years ago in PS Magazine…

Lee does have true”die lock rings” with the rubber O ring. They work very well and you should give them a try. I have a dimple on my press to match up with a mark on the lock ring to always return the die to the same place.