|

|

April 14th, 2012

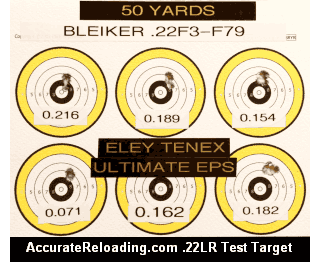

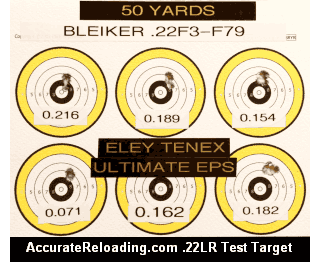

In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below. In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below.

The results are fascinating to say the least (and perhaps eye-opening). The tester observed: “I got some amazing groups, and some which are, frankly, absurdly bad! This has re-enforced what I had experienced with 22 ammo in the past — that is being consistently inconsistent.”

While we strongly caution that .22LR rimfire ammo may work well in one gun and not another, and ammo performance can be improved through the use of barrel tuners, the AccurateReloading.com research provides invaluable guidance for smallbore shooters. Overall, the testers burned through over 4,000 rounds of ammo, and you can see the actual test targets online. To read all the test reports, and view target photos visit AccurateReloading.com.

The lists below rank the average accuracy (by brand) of five, 5-shot groups shot at 50, 75, and 100 yards. CLICK HERE for Complete Test Results with target photos.

| 50-Yard Results |

75-Yard Results |

100-Yard Results |

0.162 Eley Tenex Ultimate EPS

0.164 Lapua Midas Plus

0.177 Lapua Polar Biathlon

0.187 Eley Match EPS

0.193 Eley Match

0.203 Lapua Midas M

0.215 Lapua Center X

0.216 Western Value Pack

0.229 Lapua Signum

0.241 Lapua Master L

0.243 Eley Pistol Match

0.256 Olin Ball

0.256 Akah X-Zone

0.261 Lapua Midas L

0.261 Lapua Master M

0.263 Eley Tenex Semi Auto

0.270 Lapua Super Club

0.272 Eley Tenex

0.303 Lapua Standard Plus

0.312 CCI Standard Velocity

0.319 RWS R 50

0.319 Eley Standard

0.328 SK High Velocity

0.339 Eley Club Xtra

0.340 Winchester T22

0.356 Federal Champion

0.362 Eley Subsonic HP

0.371 CCI Mini Mag

0.376 Federal American Eagle

0.377 Norinco Target

0.380 Sellier & Bellot Club

0.384 Eley Club

0.387 Eley Sport

0.388 Totem

0.392 Swartklip Match Trainer

0.398 Federal Gold Medal

0.403 Swartklip HV

0.409 Eley Match Xtra Plus

0.424 Sellier & Bellot Std

0.443 Remington Target

0.461 Lapua Crow HP

0.475 Eley Silhouex

0.479 Magtech

0.498 Eley High Velocity

0.513 Winchester Super X

0.516 Kassnar Concorde

0.539 CCI Blazer

0.560 Winchester Supreme Pistol

0.576 Norinco Pistol Revolver

0.593 SK Standard

0.611 Sellier And Bellot HP

0.626 SK Standard HP

0.686 Logo HV

0.956 Pobjeda Target |

0.274 Lapua Center X

0.283 Lapua Standard Plus

0.295 Eley Tenex Ultimate EPS

0.307 Lapua Midas M

0.329 Lapua Master M

0.346 Eley Match

0.373 Lapua Polar Biathlon

0.399 RWS R 50

0.432 Lapua Midas L

0.448 Eley Tenex Semi Auto

0.467 Eley Match EPS

0.474 Lapua master L

0.491 Eley Match Xtra Plus

0.494 CCI Standard

0.496 Eley Subsonic HP

0.507 Eley Sport

0.512 Federal American Eagle

0.513 SK High Velocity

0.514 Eley Standard

0.516 Eley Tenex

0.516 Lapua Crow HP

0.532 Western Value Pack

0.533 Fed. Champion Target

0.535 Lapua Midas Plus

0.564 Akah X Zone

0.566 Olin Ball

0.573 Eley Club Xtra

0.616 Lapua Signum

0.631 Winchester T22

0.639 Swartklip HV HP

0.641 Eley Club

0.642 Eley Silhouex

0.647 CCI Mini Mag

0.679 Eley Pistol Match

0.682 Swartklip Match Trainer

0.690 Federal Gold Medal

0.692 Remington HV

0.703 Lapua Super Club

0.720 Winchester Super X

0.738 Eley High Velocity

0.759 Kassnar Concorde

0.765 Sellier And Bellot Club

0.770 Winch. Supreme Pistol

0.770 Norinco target

0.775 CCI Blazer

0.802 Norinco Pistol Revolver

0.841 LVE Logo HV

0.855 Sellier & Bellot Std

0.871 Magtech

0.923 Sellier & Bellot HP

0.934 SK Standard HP

1.017 Remington Target

1.257 Totem Standard

1.442 SK Standard

1.578 Pobjeda target |

0.455 Eley Match

0.510 Lapua Midas Plus

0.549 Lapua Midas M

0.611 Lapua Polar Biathlon

0.611 Eley Tenex Ultimate EPS

0.619 Eley Match EPS

0.622 Eley Club

0.630 Lapua Center X

0.631 RWS R50

0.679 Eley Tenex Semi Auto

0.694 Lapua Midas L

0.729 Eley Tenex

0.739 Lapua Master L

0.753 Lapua Super Club

0.785 Lapua Master M

0.831 Eley Sport

0.851 Eley Match Xtra

0.859 Lapua Standard Plus

0.867 Akah X-Zone

0.877 Eley Pistol Match

0.907 Norinco Target

0.924 Eley Silhouex

0.939 CCI Standard

0.952 Eley Subsonic HP

0.963 Magtech

0.970 Olin Ball

0.978 Kassnar Concorde

0.995 Eley Club Xtra

1.009 Western Value Pack

1.032 Federal Champion

1.087 Norinco Pistol Revolver

1.100 CCI Mini Mag

1.112 Lapua Crow HP

1.143 Winchester T22

1.142 Federal Gold Medal

1.144 federal American Eagle

1.156 Swartklip Hollo Point

1.165 Lapua Signum

1.170 Swartklip Match Trainer

1.175 Fed. Champion Value Pk

1.182 SK high Velocity

1.201 Totem

1.224 Winchester Super X

1.358 Eley Standard

1.367 Remington High Velocity

1.375 CCI Blazer

1.414 Eley High Velocity

1.450 Remington Target

1.504 LVE Logo

1.813 SK Standard

1.879 S&B Club

1.947 S&B Hollow Point

2.073 SK Standard HP

2.221 S&B Standard

2.266 Pobjeda Target |

April 7th, 2012

This past weekend, Forum member Ron Boyd shot a 1.462″ five-shot Light Gun group at 1000 yards in an IBS benchrest match at the MidWest Benchrest Club in Yukon, Missouri. Ron shot a 6mm Dasher with Bartlein barrel and PR&T stock. Ron’s 1.462″ group is 0.065″ off the existing IBS 1000-yard Light Gun record. Ron’s group also happens to be .011″ smaller than the current NBRSA 1K Light Gun record, 1.473″ shot by Bill Schrader in 2002. (But this is not counted by the NBRSA since Ron shot in an IBS match.) Ron’s group was shot in the first relay of the day, in good conditions. The group had three (3) shots clustered in under one-third inch (0.03 MOA)! This past weekend, Forum member Ron Boyd shot a 1.462″ five-shot Light Gun group at 1000 yards in an IBS benchrest match at the MidWest Benchrest Club in Yukon, Missouri. Ron shot a 6mm Dasher with Bartlein barrel and PR&T stock. Ron’s 1.462″ group is 0.065″ off the existing IBS 1000-yard Light Gun record. Ron’s group also happens to be .011″ smaller than the current NBRSA 1K Light Gun record, 1.473″ shot by Bill Schrader in 2002. (But this is not counted by the NBRSA since Ron shot in an IBS match.) Ron’s group was shot in the first relay of the day, in good conditions. The group had three (3) shots clustered in under one-third inch (0.03 MOA)!

This is truly a spectacular achievement. We think this has to been one of the smallest five-shot groups ever shot at 1000 yards, and probably the smallest ever with a 6mm cartridge. At 1000 yards, 1 MOA is 10.47″. This means that Ron’s group measured in at 0.1396 MOA! To give you an idea of how small Ron’s group really was, at left is a 1.462″ circle shown at 100% scale, along with a quarter at 100% scale.* The circle represents the center-to-center distance of Ron’s five shots at 1000 yards. Total vertical dispersion was just under 1.2″ for five shots. The vertical for the top four shots (measured with OnTarget software) was just 0.398″! Shown below is a flat-bed scan of the actual target. Notice the tight cluster of 3 shots touching. That’s a dime in the photo added for scale. This is truly a spectacular achievement. We think this has to been one of the smallest five-shot groups ever shot at 1000 yards, and probably the smallest ever with a 6mm cartridge. At 1000 yards, 1 MOA is 10.47″. This means that Ron’s group measured in at 0.1396 MOA! To give you an idea of how small Ron’s group really was, at left is a 1.462″ circle shown at 100% scale, along with a quarter at 100% scale.* The circle represents the center-to-center distance of Ron’s five shots at 1000 yards. Total vertical dispersion was just under 1.2″ for five shots. The vertical for the top four shots (measured with OnTarget software) was just 0.398″! Shown below is a flat-bed scan of the actual target. Notice the tight cluster of 3 shots touching. That’s a dime in the photo added for scale.

Ron Boyd’s 6mm Dasher Load Ron Boyd’s 6mm Dasher Load

Ron loaded a stout charge of Long Range Match surplus powder with Spencer 103gr bullets seated about .010″ OFF the lands. The bullets were “right out of the box”, NOT pointed. This powder has burn-rate characteristics very similar to Alliant Reloder 15, and Ron used his regular RL15 charge, adjusted by half a grain or so. Ron was using no-neck-turn “brown-box” Lapua 6BR brass formed into the 40° improved 6mm Dasher case. The unturned, loaded case necks measure about 0.2695″, yielding .0015″ total clearance in a 0.271″ chamber. The brass used for the 1.462″ group had seven previous firings. Ron anneals his brass after every firing using a Benchsource annealing machine. Ron told us: “The Benchsource is the greatest annealing machine there is, as far as I’m concerned.” Ron ultrasonically cleans his brass and then tumbles his brass after the ultrasound process. He does NOT use an internal neck lubricant. He does NOT uniform his primer pockets and he does NOT ream his flashholes. Ron believes this load was running “right around 3000 fps”, but he has not chron’d it yet using the new Bartlein barrel. Ron loaded a stout charge of Long Range Match surplus powder with Spencer 103gr bullets seated about .010″ OFF the lands. The bullets were “right out of the box”, NOT pointed. This powder has burn-rate characteristics very similar to Alliant Reloder 15, and Ron used his regular RL15 charge, adjusted by half a grain or so. Ron was using no-neck-turn “brown-box” Lapua 6BR brass formed into the 40° improved 6mm Dasher case. The unturned, loaded case necks measure about 0.2695″, yielding .0015″ total clearance in a 0.271″ chamber. The brass used for the 1.462″ group had seven previous firings. Ron anneals his brass after every firing using a Benchsource annealing machine. Ron told us: “The Benchsource is the greatest annealing machine there is, as far as I’m concerned.” Ron ultrasonically cleans his brass and then tumbles his brass after the ultrasound process. He does NOT use an internal neck lubricant. He does NOT uniform his primer pockets and he does NOT ream his flashholes. Ron believes this load was running “right around 3000 fps”, but he has not chron’d it yet using the new Bartlein barrel.

Ron Boyd’s 6mm Dasher Light Gun

Ron’s 17-lb Light Gun featured a BAT SV Action, Bartlein 30″ 1:8″ twist, 0.237″ land barrel, and Precision Rifle & Tool “Hammerhead” benchrest stock with 5″-wide wings in front. This stock weighs 4 lbs 1 oz. with an aluminum butt plate and is about 36.5″ long with integrated rails on the bottom of the “wings”. Ron’s friends Rich Griffin and Jerry Kloeppel did the chambering and bedding. Ron recently put the Bartlein barrel on the gun. Ron estimates that the barrel had only 40 rounds through it when it produced the 1.462″ group. Ron tells us: “This new barrel is great, and the 5″ PR&T stock really works. I luckily pulled the trigger at the right time.” Ron told us that this rifle shot in the high ones/low twos at 100 yards during testing.

PR&T Hammerhead Stock (catalog photo)

*The circle and quarter should appear “true size” when viewed at the most common monitor resolution. If you are running a higher resolution on your monitor, the illustration will appear small than actual size.

April 3rd, 2012

The impressive new Lapua Rimfire Service Center opens in Mesa, Arizona on April 24, 2012. Patterned after the world-renowned Lapua Service Center in Schönebeck, Germany, this facility gives American shooters the same opportunity to test various types and lots of rimfire ammunition, in their own firearms, under ideal conditions. This assures that customers can purchase not only the best type of ammunition for his or her particular rifle, but also the specific lots of ammo that perform best. Experienced competitive rimfire shooters know that the ability to select a particular lot of ammunition that performs best in their firearm(s) means a world of difference in a match. The impressive new Lapua Rimfire Service Center opens in Mesa, Arizona on April 24, 2012. Patterned after the world-renowned Lapua Service Center in Schönebeck, Germany, this facility gives American shooters the same opportunity to test various types and lots of rimfire ammunition, in their own firearms, under ideal conditions. This assures that customers can purchase not only the best type of ammunition for his or her particular rifle, but also the specific lots of ammo that perform best. Experienced competitive rimfire shooters know that the ability to select a particular lot of ammunition that performs best in their firearm(s) means a world of difference in a match.

Until now, the ability of a shooter to do this vital testing was dependent on the small quantities of ammunition of various lots on hand, generally without any guarantee that a vendor could provide more of whatever lot turned in the best results. Lapua will maintain an inventory of approximately two million rounds of rimfire ammunition on site — a wide variety of different types and grades, and many different lots. Lapua states that: “Our goal is that you, the shooter, will be able to purchase sufficient quantities of the best ammo for your needs. In future matches, you’ll be able to know that the ammo you take to the line is truly the very best.”

|

CLICK “PLAY” to HEAR Adam Braverman TALK about Lapua’s New Arizona Rimfire Test Center:

|

[haiku url=”http://accurateshooter.net/Video/bravermanmemo.mp3″ title=”Braverman Voice Memo”] |

High-Tech Electronic Targets in 100m Test Tunnel

At the heart of Lapua’s operation is a new 100m test tunnel. Fully instrumented with state-of-the-art Meyton electronic targeting systems, the Mesa facility offers the unique ability to test ammunition at both 50 meters and 100 meters, simultaneously with a single string. As the bullets pass through the screen at 50 meters, a group will appear on the first targeting screen. As the bullet continues its flight downrange, it will also be picked up on a second screen at the 100 meter line. This approach allows the shooter to see, instantly, which ammunition performs best at both 50m and 100m distances.

Shooters are encouraged to visit the new Rimfire Service Center. Testing is by appointment only, with a $50.00 range fee. For more information, visit www.Lapua.com or email lapua [at] nammoinc.com. The Lapua Rimfire Service Center is located at 4051 N. Higley Road, Mesa, AZ 85215, on the grounds of Nammo Tactical Ammunition. The Lapua Service Center, just 20 miles from Phoenix Sky Harbor Int’l Airport, is easy to reach by major roadways. Not far away, in the general Phoenix area, you’ll find a wide variety of hotels, restaurants, golf courses, plus the outstanding Ben Avery Shooting Range.

February 9th, 2012

Forum member Skeeter has a 6mm Dasher falling block varmint rifle. The Dasher case is based on the 6mm BR Norma cartridge with the shoulder blown forward about 0.100″ and out to 40°. This gives the Dasher roughly 3.5 grains added capacity compared to the standard 6BR.

Last year, Skeeter needed to form 300 cases for varmint holiday. Skeeter decided to fire-form his brass without bullets. This method avoids barrel wear* and saves on components. There are various ways to do this, but Skeeter chose a method using pistol/shotgun powder, some tissue to hold the powder in place, Cream of Wheat filled to within an 1/8″ of top of the neck, and a “plug” of tissue paper to hold it all in place. Shown below are cases filled with a pistol/shotgun powder charge topped with Cream of Wheat and then a tissue paper plug.

To ensure the case headspaced firmly in his Dasher chamber, Skeeter created a “false shoulder” where the new neck-shoulder junction would be after fire-forming. After chamfering his case mouths, Skeeter necked up all his cases with a 0.257″ mandrel (one caliber oversized). Then he used a bushing neck-sizing die to bring the top half of the neck back down to 0.267″ to fit his 0.269″ chamber. The photo below shows how the false shoulder is created.

After creating the false shoulder, Skeeter chambered the cases in his rifle to ensure he could close the bolt and that he had a good “crush fit” on the false shoulder, ensuring proper headspace. All went well.

The next step was determining the optimal load of pistol powder. Among a variety of powders available, Skeeter chose Hodgdon Titewad as it is relatively inexpensive and burns clean. The goal was to find just the right amount of Titewad that would blow the shoulder forward sufficiently. Skeeter wanted to minimize the amount of powder used and work at a pressure that was safe for his falling block action.

Working incrementally, Skeeter started at 5.0 grains of Titewad, working up in 0.5 grain increments. As you can see, the 5.0 grain charge blew the shoulder forward, but left it a hemispherical shape. At about 7.0 grains of Titewad, the edge of the shoulder and case body was shaping up. Skeeter decided that 8.5 grains of Titewad was the “sweet spot”. He tried higher charges, but the shoulder didn’t really form up any better. It will take another firing or two, with a normal match load of rifle powder and a bullet seated, to really sharpen up the shoulders. Be sure to click on the “View Larger Image” link to get a good view of the cases.

The process proved to be a success. Skeeter now has hundreds of fire-formed Dasher cases and he hasn’t had to put one bullet through his nice, new match-grade barrel. The “bulletless” Cream of Wheat method allowed him to fire-form in a tight-necked barrel without neck-turning the brass first. The only step now remaining is to turn the newly Dasher-length necks down about .0025″ to fit his 0.269″ chamber. (To have no-turn necks he would need an 0.271″ or 0.272″ chamber).

Skeeter didn’t lose a single case: “As for the fire-forming loads, I had zero split cases and no signs of pressure in 325 cases fire-formed. Nor did I have any misfires or any that disbursed COW into the action of the firearm. So the COW method really worked out great for me and saved me a lot of money in powder and bullets.” To learn more about Skeeter’s fire-forming process, read this Dasher Fire-Forming Forum Thread.

*Skeeter did have a fire-forming barrel, but it was reamed with a .269 chamber like his 10-twist Krieger “good” barrel. If he fire-formed with bullets, he would have to turn all 300 necks to .267″ BEFORE fire-forming so that loaded rounds would fit in the chamber. Judging just how far to turn is problematic. There’s no need to turn the lower part of the neck that will eventually become shoulder–but how far down the neck to turn is the issue. By fire-forming without bullets now he only has to turn about half the original neck length, and he knows exactly how far to go.

February 2nd, 2012

Many precision-oriented shooters are discovering that the “middle ground” in cartridge size is optimal for the 100gr to 115gr match bullets. With a mid-sized cartridge, you can run these pills faster than a 6BR or Dasher, without giving up much, if any, accuracy to a 6BR or BR Improved. The most accurate 600-yard rifle at this Editor’s local club is a 6-6.5×47. It can shoot as tight as a 6BR past 300 yards, plus it offers better ballistics, pushing 105 Bergers at 3140 fps.

If you’re considering a mid-sized 6mm cartridge for your next rifle, you’re probably wondering WHICH mid-size 6mm cartridge is best. We are often asked “what’s the difference between the 6×47 Swiss Match, the 6XC, and the 6.5×47 Lapua necked down to 6mm?” All three cartridges have 30° shoulders and fit a .308-sized boltface. However, alone among the three, the 6mm-6.5×47 has a small primer pocket and small flash hole. The 6×47 Swiss Match (made by RUAG), and the 6XC (produced by Norma), have a large primer pocket and large flash hole, just like a .308 Winchester. If you’re considering a mid-sized 6mm cartridge for your next rifle, you’re probably wondering WHICH mid-size 6mm cartridge is best. We are often asked “what’s the difference between the 6×47 Swiss Match, the 6XC, and the 6.5×47 Lapua necked down to 6mm?” All three cartridges have 30° shoulders and fit a .308-sized boltface. However, alone among the three, the 6mm-6.5×47 has a small primer pocket and small flash hole. The 6×47 Swiss Match (made by RUAG), and the 6XC (produced by Norma), have a large primer pocket and large flash hole, just like a .308 Winchester.

Forum member DesertLefty has provided a line-up photo, with 6mmBR and .260 Rem cases provided for comparison. As you can see, the three mid-sized cases (6x47SM, 6.5×47 Lapua, and 6XC) are very similar. The Swiss Match has the longest neck, while the 6XC enjoys the highest capacity. But performance is very similar among the three cartridges (with the 6.5×47 necked down to 6mm). The same powders, (particularly H4350, Reloder 17, and IMR 4007SSC) work well in the 6×47 SM, the 6XC, and the 6-6.5×47 Lapua. The parent 6.5×47 Lapua case is rated at 63090 psi, while the new CIP rating for the 6XC is 63844 psi (4400 BAR). Both the necked-down Lapua brass and the Norma-brand 6XC brass can hold stout loads. Though the 6mm-6.5×47 has slightly less powder capacity than the 6XC, max velocities with 105-108gr bullets are quite similar. However, you should not substitute loads from the 6XC directly to the 6mm-6.5×47 or vice-versa. Because of the different case capacities and primer sizes, you should work up loads separately for each cartridge.

October 13th, 2011

NRA Headquarters in Fairfax, Virginia was recently visited by Raimo Helasmaki of the Nammo Group. Based in Finland, Nammo is the parent company of Lapua, manufacturer of ammunition and reloading components. Helasmaki, Executive VP of Nammo’s Small Caliber Division, was in the Washington, DC area for the annual Association of the U.S. Army (AUSA) trade show. We’re glad to see a top European executive travel to the USA where he can get direct feedback from American shooters on his company’s product line.

CLICK HERE for AUSA 2011 Annual Meeting & Exposition Web Site

Lapua was founded in 1923 as a state-owned cartridge company. Over the years, Lapua kept perfecting its product in response to the needs of its worldwide customer base. Lapua remains an industry leader, creating some of the most accurate ammunition, brass, and bullets on the planet. Proof is in the performance — 80% of the Biathlon medals at the 2010 Winter Olympic in Munich were won by athletes using Lapua ammunition.

Helasmaki met with several NRA officials in Fairfax, including NRA’s General Operation Executive Director Kayne Robinson. To wrap things up, he toured the National Firearms Museum, guided by Phil Schreier, Senior Museum curator (at left in photo above).

Photos and story courtesy The NRA Blog.

September 13th, 2011

Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of cartridge brass. Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of cartridge brass.

The test results revealed significant differences in the percentages of copper and zinc in the different brands. Copper content ranged from a low of 72% by mass (Winchester, S&B) to a high of 80% by mass (Remington). Zinc, which adds hardness to the alloy, ranged from a low of 20% by mass (Federal) to a high of 36% (‘brown box’ Lapua). Interestingly, the tests, as reported by Forum Member Fred Bohl, revealed that the alloy in the new ‘blue box’ 6mmBR Lapua brass is different than the alloy in Lapua’s older ‘brown box’ 6mmBR brass. Specifically, the ‘blue box’ 6mmBR brass has more copper and less tin (by mass). Here’s a summary of the X-Ray Fluorescence spectrometry tests:

This testing was done at major science laboratory, using high-grade X-Ray Spectrometry Analyzing equipment. Fred reports that: “The data was run by one of the club members with the permission of the test lab supervisor who is also a club member and shooter. The data in original output reports was far more detailed about trace elements at lower orders of magnitude primarily from surface contaminants (some were rerun after establishing a repeatable cleaning procedure)”. The testing process is discussed in this Shooters’ Forum thread.

We do NOT have the metallurgical expertise to infer that any particular alloy shown above is “better” than another. The alloy “blend” is merely one of many variables that can have an impact on the performance and quality of the finished product. Annealing times/methods differ and some cartridge brass is extruded while other cartridge brass is made with the traditional drawing process. Readers should not presume, on reading the above chart, that they can identify the “best shooting” brass simply based on the constituent metals in the various alloys.

General Observations about Cartridge Brass Alloys

With the cartridge brass X-Ray Spectrometry results in hand, Fred Bohl hoped to find out what “real world” conclusions (if any) we could draw from the raw data. Fred sent the test results to some knowledgeable metallurgists, soliciting their comments. Fred explains: “When I first posted this information [in the Shooters’ Forum], I had hoped to elicit replies from expert metallurgists and to initiate a useful discussion. From [their replies] I distilled the following ‘consensus’ comments”:

1. The range of Copper/Zinc ratios suitable for use in cartridge making by typical processes is 85/15 to 65/35 (% by weight or mass).

2. The range of Copper/Zinc ratios suitable for use in cartridges intended for reloading is 80/20 to 70/30. Above 80% copper, the resulting case would tend to be too soft and difficult to attain the distribution of hardness desired (harder at the base and softer at the neck). Below 70% copper the resulting case would tend to be too hard, would work harden too quickly and require frequent annealing. [Editor: That said, the ‘brown box’ 6mmBR Lapua brass, with 62% copper/36% zinc content, enjoys an unrivaled reputation for both accuracy and its ability to perform well after a dozen or more reloading cycles. We know 30BR shooters who have shot the same old-style Lapua brass (6mmBR parent case) more than 50 times. So maybe the “expert” view needs re-thinking.]

3. As the percentage of zinc increases, the tensile strength, yield strength and hardness tend to increase. However, above 35% zinc, while tensile strength will continue to tend to increase, both yield strength and hardness will tend to begin to decrease.

4. The trace additives of iron and/or silicon are used to control the processing characteristics of the alloy. Trace additions of chromium will improve corrosion resistance and give a shinier surface (both largely cosmetic).

5. Selection of the alloy and additives is a trade off among: end use desired properties; processing time and yield; and cost of materials. For example, the classic 70/30 cartridge brass was considered an optimum combination of corrosion resistance and hardness for single use by the military with good process yield at acceptable material cost.

6. All of my responding experts were surprised by the brown box Lapua alloy except for the oldest. He remembered using an almost identical alloy late in WWII when copper was in very short supply for military small arms ammunition.

August 27th, 2011

For its web customers, Creedmoor Sports is running a sale on Sierra Bullets and select Lapua cartridge brass. You can get 5% off a big 500-count box of Sierra Bullets, and save 10% on Lapua .260 Rem or .338 Lapua Magnum brass. Discounts are good through 11:59 pm, Sunday, August 28, 2011.

Sierra Bullets, 500-ct Box (Any Caliber)

Save 5% with Coupon Code BULLET 2011

Lapua Brass — Weekend Special through 8/28/2011

.260 Rem Brass, $87.95 — marked down from $96.95

.338 Lapua Mag Brass, $229.95 — marked down from $254.95

July 21st, 2011

If you read our 2011 Super Shoot Report by James Mock, you’ll see that Vihtavuori N133 powder is the overwhelming choice of top short-range benchrest shooters for loading their 6PPCs. Other Vihtavuori powders, such as N135, N150, and N550 are also very popular for other match and hunting cartridges. If you read our 2011 Super Shoot Report by James Mock, you’ll see that Vihtavuori N133 powder is the overwhelming choice of top short-range benchrest shooters for loading their 6PPCs. Other Vihtavuori powders, such as N135, N150, and N550 are also very popular for other match and hunting cartridges.

If you currently use a Vihtavuori (VV) powder, or you plan to try a Vihtavuori powder in the near future, visit www.Lapua.com soon. Load info on Lapua’s Vihtavuori Reloading Data Page has been updated (or added) for the following calibers: .222 Remington, .223 Remington, .223 WSSM (new caliber data), .22-250 Remington, 6.5 Grendel, 6.5×47 Lapua, and 7.62x53R. In the updated tables, you’ll find VV powder recipes for a wide variety of bullets from Hornady, Lapua, Nosler, Sierra, Speer and other bullet-makers.

Though these recipes are fairly conservative, always start low and work up gradually when using a new powder for the first time. Likewise, you should back off your load if you change ANY component or if you have fitted a new barrel to your rifle.

Vihtavuori N100 Series

The N100 series powders are single-base powders used mainly in rifle calibers. There are ten N100 series powders with different burning rates and suitability from the .17 Remington up to the .458 Winchester Magnum and two special powders for .50 BMG.

N500 Series

The N500 series powders are impregnated extruded rifle powders with Nitroglycerol added as extra energy component. If higher loading densities and more energy are needed, N500 series powders are competent alternatives for the N100 series powders. N500 series High Energy powders are available in five different burning rates.

Story tip by EdLongrange. We welcome submissions from our readers.

June 7th, 2011

Dispelling Some 6mm BRX Myths, by Robert Whitley Dispelling Some 6mm BRX Myths, by Robert Whitley

I recently had an interesting and fact-filled conversation with Bob Crone (the inventor of the 6mm BRX) about his BRX. Bob actually called me because he was concerned that there are a lot of myths and about his 6mm BRX and he wanted to “set the record straight” on a few things. Here’s my summary of some topics we discussed:

Myth One: Bob made his 6mm BRX chamber by running a 6mm BR reamer in too deep.

Truth: There is no truth to Myth One. Bob said he specifically designed the BRX reamer and had it made with the head space he specified and a neck length appropriate for his newly designed 6mm BRX wildcat cartridge.

Myth Two: In the course of making up his 6mm BRX, Bob had a version with a .120″ longer head space than a 6mm BR Norma.

Truth: Bob was clear that his original design for the 6mm BRX always had a .100″ longer head space than a 6mm BR and that he never deviated from that. Right after Bob started working with his 6mm BRX, Bill Shehane came forward with a 6mm BRX version he made up that had a .120″ longer head space, and thus the confusion started. In truth, the original 6mm BRX always was (and still is) a chambering with a head space .100″ longer than a 6mm BR Norma. Truth: Bob was clear that his original design for the 6mm BRX always had a .100″ longer head space than a 6mm BR and that he never deviated from that. Right after Bob started working with his 6mm BRX, Bill Shehane came forward with a 6mm BRX version he made up that had a .120″ longer head space, and thus the confusion started. In truth, the original 6mm BRX always was (and still is) a chambering with a head space .100″ longer than a 6mm BR Norma.

Myth Three: The BRX was originally set up for 105-107gr bullets.

Truth: Bob said he set up his original reamer with a zero freebore and he has his gunsmith use a throater to throat whatever chamber was being made to where he wanted a particular bullet to touch the lands. Bob said he originally started with a 1:10″ twist barrel and shot a bunch of the 95gr VLDs and also 87gr bullets. Later he used an 8.5″ twist barrel for the heavier bullets.

Myth Four: The original BRX was set up also for use with Remington BR Brass.

Truth: Bob said he always used Lapua brass. He originally was an avid reader of Precision Shooting magazine and saw that the .262″ neck-turn neck was working real well with the 6 PPC and 6mm BR bench rest shooters and he decided to try to go with something that was already working well for 6mm shooters. He says his original reamer had a .262″ neck, but he also has a .272″ “no-neck-turn” version that he used on some of his rifles. He said the Lapua brass was so good and consistent, that for some rifles he just “didn’t want to mess with it” so he went with the “no-neck-turn” .272″ neck too.

Myth Five: The “false shoulder” method was used to make brass. Myth Five: The “false shoulder” method was used to make brass.

Truth: Bob said he never used the “false shoulder” method to make 6mm BRX brass, he just loaded 6mm BR brass with a bullet well into the lands of the BRX chamber and fire-formed brass that way. He noted that the accuracy with some of the fire-forming rounds was “outrageous” (i.e. outrageously good that is), so much so, they were shot in matches sometimes.

Myth Six: The 6mm BRX has a blown-out or straightened out body.

Truth: Bob said he kept the basic body taper of the 6mm BR cartridge. He wanted the cartridge to be an easy and inexpensive (but high performance) 6mm wildcat, and the original design was (and still is) set up to use readily available 6mm BR dies (up off the shell holder about .100″ from the normal position).

Author’s note: It was a most enjoyable experience to talk to Bob Crone. He is not only still passionate about his 6mm BRX, but he has a commanding knowledge of it as well.

Reamer Print provided by AR-X Enterprises LLC, www.6mmAR.com.

|

In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below.

In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below.

This past weekend, Forum member Ron Boyd shot a 1.462″ five-shot Light Gun group at 1000 yards in an IBS benchrest match at the

This past weekend, Forum member Ron Boyd shot a 1.462″ five-shot Light Gun group at 1000 yards in an IBS benchrest match at the  This is truly a spectacular achievement. We think this has to been one of the smallest five-shot groups ever shot at 1000 yards, and probably the smallest ever with a 6mm cartridge. At 1000 yards, 1 MOA is 10.47″. This means that Ron’s group measured in at 0.1396 MOA! To give you an idea of how small Ron’s group really was, at left is a 1.462″ circle shown at 100% scale, along with a quarter at 100% scale.* The circle represents the center-to-center distance of Ron’s five shots at 1000 yards. Total vertical dispersion was just under 1.2″ for five shots. The vertical for the top four shots (measured with OnTarget software) was just 0.398″! Shown below is a flat-bed scan of the actual target. Notice the tight cluster of 3 shots touching. That’s a dime in the photo added for scale.

This is truly a spectacular achievement. We think this has to been one of the smallest five-shot groups ever shot at 1000 yards, and probably the smallest ever with a 6mm cartridge. At 1000 yards, 1 MOA is 10.47″. This means that Ron’s group measured in at 0.1396 MOA! To give you an idea of how small Ron’s group really was, at left is a 1.462″ circle shown at 100% scale, along with a quarter at 100% scale.* The circle represents the center-to-center distance of Ron’s five shots at 1000 yards. Total vertical dispersion was just under 1.2″ for five shots. The vertical for the top four shots (measured with OnTarget software) was just 0.398″! Shown below is a flat-bed scan of the actual target. Notice the tight cluster of 3 shots touching. That’s a dime in the photo added for scale. Ron Boyd’s 6mm Dasher Load

Ron Boyd’s 6mm Dasher Load Ron loaded a stout charge of

Ron loaded a stout charge of

The impressive new Lapua Rimfire Service Center opens in Mesa, Arizona on April 24, 2012. Patterned after the world-renowned Lapua Service Center in Schönebeck, Germany, this facility gives American shooters the same opportunity to test various types and lots of rimfire ammunition, in their own firearms, under ideal conditions. This assures that customers can purchase not only the best type of ammunition for his or her particular rifle, but also the specific lots of ammo that perform best. Experienced competitive rimfire shooters know that the ability to select a particular lot of ammunition that performs best in their firearm(s) means a world of difference in a match.

The impressive new Lapua Rimfire Service Center opens in Mesa, Arizona on April 24, 2012. Patterned after the world-renowned Lapua Service Center in Schönebeck, Germany, this facility gives American shooters the same opportunity to test various types and lots of rimfire ammunition, in their own firearms, under ideal conditions. This assures that customers can purchase not only the best type of ammunition for his or her particular rifle, but also the specific lots of ammo that perform best. Experienced competitive rimfire shooters know that the ability to select a particular lot of ammunition that performs best in their firearm(s) means a world of difference in a match.

If you’re considering a mid-sized 6mm cartridge for your next rifle, you’re probably wondering WHICH mid-size 6mm cartridge is best. We are often asked “what’s the difference between the 6×47 Swiss Match, the 6XC, and the 6.5×47 Lapua necked down to 6mm?” All three cartridges have 30° shoulders and fit a .308-sized boltface. However, alone among the three, the 6mm-6.5×47 has a small primer pocket and small flash hole. The 6×47 Swiss Match (made by RUAG), and the 6XC (produced by Norma), have a large primer pocket and large flash hole, just like a .308 Winchester.

If you’re considering a mid-sized 6mm cartridge for your next rifle, you’re probably wondering WHICH mid-size 6mm cartridge is best. We are often asked “what’s the difference between the 6×47 Swiss Match, the 6XC, and the 6.5×47 Lapua necked down to 6mm?” All three cartridges have 30° shoulders and fit a .308-sized boltface. However, alone among the three, the 6mm-6.5×47 has a small primer pocket and small flash hole. The 6×47 Swiss Match (made by RUAG), and the 6XC (produced by Norma), have a large primer pocket and large flash hole, just like a .308 Winchester.

Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of cartridge brass.

Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of cartridge brass.

If you read our

If you read our  Dispelling Some 6mm BRX Myths, by

Dispelling Some 6mm BRX Myths, by  Truth: Bob was clear that his original design for the 6mm BRX always had a .100″ longer head space than a 6mm BR and that he never deviated from that. Right after Bob started working with his 6mm BRX, Bill Shehane came forward with a 6mm BRX version he made up that had a .120″ longer head space, and thus the confusion started. In truth, the original 6mm BRX always was (and still is) a chambering with a head space .100″ longer than a 6mm BR Norma.

Truth: Bob was clear that his original design for the 6mm BRX always had a .100″ longer head space than a 6mm BR and that he never deviated from that. Right after Bob started working with his 6mm BRX, Bill Shehane came forward with a 6mm BRX version he made up that had a .120″ longer head space, and thus the confusion started. In truth, the original 6mm BRX always was (and still is) a chambering with a head space .100″ longer than a 6mm BR Norma. Myth Five: The “false shoulder” method was used to make brass.

Myth Five: The “false shoulder” method was used to make brass.