LuckyGunner.com Conducts “Epic Ammo Torture Test”

LuckyGunner.com, a leading online ammo vendor, has conducted a remarkable “torture-test” comparison of brass-cased and steel-cased .223 Rem ammunition. Four different kinds of ammo (one brass-cased, three steel-cased) were fired through four different Bushmaster AR15s — ten thousand (10,000) rounds PER GUN. The idea was to see if brass-cased ammo was better than the cheaper, steel-cased ammunition. During the course of the project, Luckygunner’s testers logged malfunctions and checked for accuracy, chamber pressure, gas port pressure, chamber wear, and overall barrel wear. At the end of the test, the well-worn barrels were sectioned to see the effect of thousands of rounds… and the results weren’t pretty.

Test Findings: For a multitude of reasons, the test crew determined that Federal brass-cased ammo was “healthier” than steel-cased ammo. The brass-cased ammo shot more accurately, had far fewer malufunctions, and produced less barrel wear. The USA-made brass-cased ammo also showed more consistent velocities. CLICK HERE to READ FULL TEST.

Watch the video below for a summary of results:

Torture Test Procedure

Four types of .223 Rem ammo were tested: Federal brass-cased 55gr FMJBT; Wolf steel-cased (polymer coating) 55gr FMJ; Tula steel-cased (polymer coating) 55gr Bi-Metal Jacket; Brown Bear steel-cased (lacquer coating) 55gr Bi-Metal Jacket. Each ammo type was paired with a specific Bushmaster AR-15. Tests were performed at various round-count stages:

- At the start: record accuracy, velocity, chamber and gas port pressures, make chamber cast

- After 2,000 rounds: record accuracy, velocity

- After 4,000 rounds: record accuracy, velocity

- After 5,000 rounds: record throat erosion, make chamber cast

- After 6,000 rounds: record accuracy, velocity

- After 8,000 rounds: record accuracy, velocity

- After 10,000 rounds: record accuracy, velocity, chamber and gas port pressures, throat erosion, extractor wear, chamber cast, barrel wear, make chamber cast.

During testing, rifles were cleaned according to a preset schedule and temperatures were monitored. After testing, LuckyGunner sectioned the barrels and made careful inspections.

Click the links below for specific data, test results, and conclusions:

- Which ammunition was most reliable?

- Which ammunition was the dirtiest?

- Which performed better, lacquer or polymer coating?

- Which ammunition maintained the highest degree of accuracy throughout the test?

- Which ammunition maintained the most consistent velocity throughout the test?

- Which ammunition caused the most throat, barrel, and extractor erosion/wear?

- What effect did the powder burn rates have on bolt cycling?

- How did the pressure at the gas port vary by ammunition type?

- How did the pressure at the chamber vary by ammunition type?

- Which is cheaper to use, after considering all the costs?

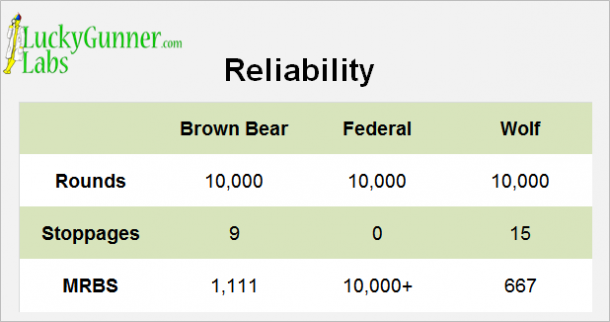

During the testing process, all malfunctions of each rifle-ammo combination were logged. The brass-cased Federal ammo was the clear winner: Federal: 10,000 rounds, 0 malfunctions. |

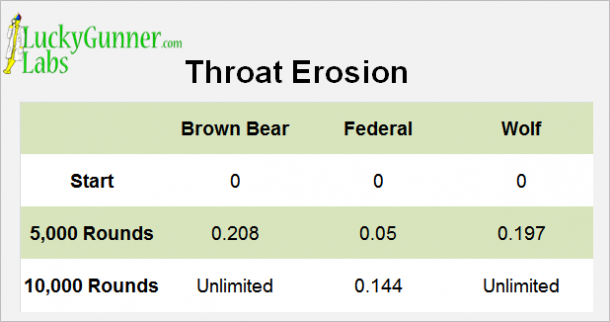

Barrel Wear and Throat Erosion

Barrel Wear and Throat Erosion

Some of the barrels didn’t make it to 10,000 rounds: “The steel cased/bimetal jacketed ammunition caused accelerated wear to the inside of their respective bores. While the barrel of the Federal carbine had plenty of life left, even after 10,000 rounds … the Wolf and Brown Bear barrels … were completely shot out by 6,000 rounds. At the end of the test, the chrome lining of the Wolf and Brown Bear barrels was almost gone from the throat forward, and the barrels had effectively become smoothbores[.] A throat erosion gauge could be dropped into the bore from the muzzle end with absolutely no resistance.”

Similar Posts:

- 25% Off Mail-In Rebate on Federal American Eagle Pistol Ammo

- Bargain Pricing on Wolf Centerfire Ammo at Powder Valley

- SOCOM Considers New 6.5 mm Chamberings for Semi-Auto Rifles

- New Ammo Site Offers $25.00 Off First Order over $200.00

- Melonite Surface Treatment for Barrels, Bolts, and Actions

Tags: .223 Rem, 5.56x45, Brown Bear, Bushmaster Test, Epic Ammo Test, Federa', LuckyGunner.com, Steel Ammo, Torture Test, Tula, Wolf

Interesting Barrel Wear and Throat Erosion figures. out .050 with a 55 grain bullet sounds about right for 5000 rounds. I shoot 77`s and 80`s or 80.5`s and the throat goes out .100 between 5000 and 6000 rounds. About 1/4 of these rounds were shot rapid fire HP Comp. This has been the case with several SS barrels of various manufacture.

Thats my change barrel point, out .100 unless it losses X count at 600 earlier as a Wilson or DPMS might. Have definitely had the longest barrel life with krieger`s.

Curse me if I’m barking up the wrong tree, but as far as I can remember barrel – throat and gas port – erosion has nothing to do with the case material. It’s a combination of the propellant gas temperature, gas species produced, gas pressure and the material properties of the bullet and barrel: for example the frictional, melting point, elemental composition and hardness characteristics.

The case material will be the major factor on the wear of the chamber and extractor, other than the materials these two components are made from. The case and its coating, if present, will also affecting the extraction and feeding process.

The bullets on the Russian made ammo are made out of steel. They are copper coated. That is where the wear is coming from. I’m glad that someone finally did a test and proved that the Russsian stuff is JUNK!