Stick, Flake, and Ball — Do You Know Your Powder Properties?

Widener’s Reloading & Shooting Supply recently published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

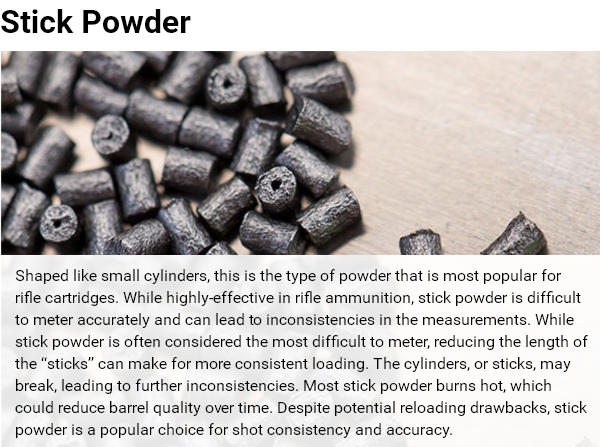

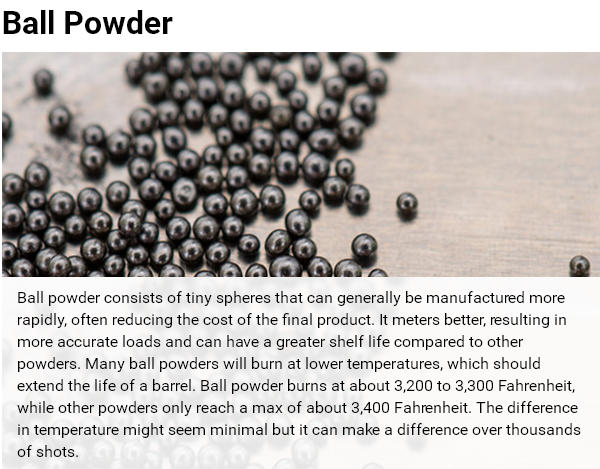

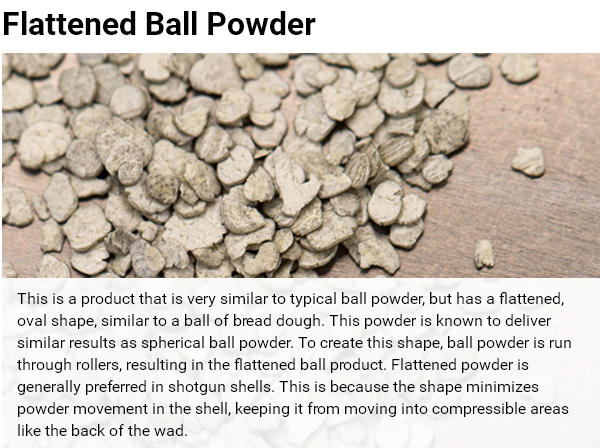

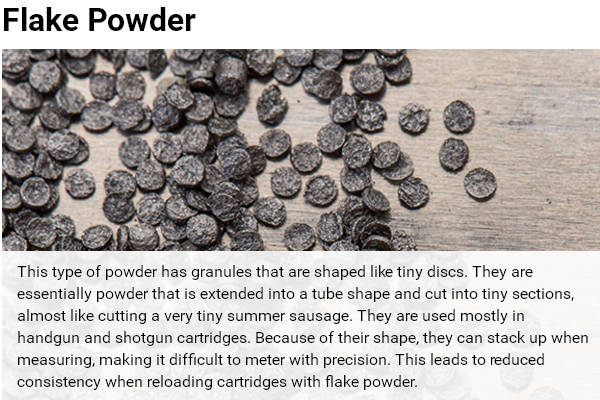

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

Similar Posts:

- Powder Types — Properties of Stick, Ball, Flake, Flattened Ball

- Widener’s Guide to Smokeless Powders

- Powder Burn Rate Comparison Table — Download HERE

- Powder Burn Rate Comparison Table — Download HERE

- Comparative Burn-Rate Chart Lists 163 Powders

Tags: Alliant, Ball Powder, Burn Rates, Extruded Powder, Flake Powder, Hodgdon Powder, Stick Powder, Wideners

On occastion I’ve noticed split case necks when using double based powder with boat tail bullets mainly w748 but also rl22 witch is extruded but also double based powder and yes I know about annealing the case necks once I had 18 out of twenty cases split in 350 mag useing 230 great boat tails in new brass I then shot a box of 20 new brass useing the same bullets with a heavy charge of imr4320with no problems,same lot of brass ?????????anyone ever see this same has happened with 30_06 and 7mm magnum,and 308 I won’t load double based powders with boatails anymore as it ruins to many caseings for me??I’m puzzeledany answers will be appreciated?