Hornady (aka Stoney Point) OAL Gauge on Sale at MidwayUSA

Now through April 30, 2009, MidwayUSA has the Hornady (formerly Stoney Point) Lock-N-Load Overall Length Gauge (item 570611) on sale for $25.99. That’s $4.50 off the regular price. Note, in addition to the Gauge itself, you’ll need a threaded modified case for each caliber you shoot, and we recommend having a comparator body with caliber-specific insert. The comparator allows you to measure from base of case to bullet ogive (rather than bullet tip).

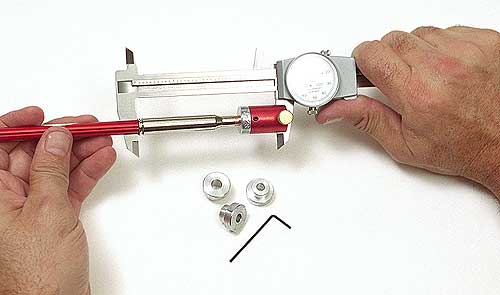

OAL Gauge shown with Comparator to allow measurement from bullet ogive.

This Editor personally uses the Hornady Overall Length Gauge to find the distance to the lands for all his centerfire rifles. With practice, using the right technique, you can achieve measurements that are very repeatable. Here’s my method:

1. After screwing the modified case securely to the gauge, insert the case (with a bullet in neck) into the chamber. Make sure the modified (threaded) case goes ALL the way into the chamber. (Note: a heavily-fouled chamber can interfere with the seating of the modified case.)

2. Slide the gray pusher rod gently forward until you feel the first, slight resistance, then stop.

3. Now with the tip of your finger, tap the gray rod gently two or three times. This should give you a good, repeatable bullet contact with the lands, without going into the rifling.

4. You do NOT want to push hard on the gray rod. This will cause the bullet to engage the rifling. That will cause the bullet to stick, and you will end up with inconsistent length-to-lands measurements.

Some folks complain that this tool is not particularly repeatable. Well, if you use and practice the technique above, I think you’ll find the opposite is true. Using the Hornady OAL Gauge with a Berger bullet in a 6PPC, I recently measured length to lands five times in a row, with a couple witnesses to the procedure. Each of the measurements was consistent within .0007″ as recorded with a set of Mitutoyo Digital calipers. The key is using the same technique and pressure every time. CLICK HERE for a complete review of the Hornady OAL Gauge, with many photos

Similar Posts:

- Cartridge Headspace 101 — Understanding the Basics

- Headspace — How to Measure This and Set Dies Accordingly

- Cartridge Headspace — How to Measure and Set Dies Properly

- Saturday Movies: Finding Length to Lands — Multiple Methods

- How to Make a Modified Case for Measuring Length-to-Lands

Tags: Bullet Seating, Lands, OAL Gauge

Just purchased the last component of this gauge (comparator); waiting for it to arrive. Anxious to try it out. Your description of the technique to obtain consistency helps considerably. Thanks, LHL

Do you carry a modified case for the Hornady AOL gage in 7.62 (not 308)? Thx Steve

I may be wrong, but he purpose of using this tool is to adjust the JUMP distance when seating bullets that is desired to be consistent to within .0005″, well under the + – tolerance allowed under SAAMI specs for chamber dimensions. I understand that the measurements are being taken from the bullet Ogive to the base of a foreign case that has not been fire formed to that chamber, yet the case is indexed against the chamber shoulder. The only accurate measurement you could obtain would be the distance from the shoulder to the lands,(a useless fact) but is still dependent on the compatibility of your comparator bushing and the seating stem in your die. Who needs that? The difference in headspace on that case will provide false OAL readings from the case base, or bolt face to the lands as compared to fire formed cases, and even then you have to guess how much the case relaxed after full expansion (estimated to be .001 – .002″) It makes sense to me to drill and tap a fire formed case to use with the tool instead of a case provided by a tool supplier. Additionally, the bushing of the comparator is providing a measurement based on the opening diameter of the bushing. If this diameter does not perfectly match the diameter of the contact point of your seating stem on the bullet, slight differences varying bullet shape of the same lot will cause inconsistencies with your OAL as the points of reference are not the same. Someone needs to design a tool that incorporates the seating stem in your die as a component of the comparative system, but you still have some inconsistency by not knowing the true dimension between the bolt face and the lands. Try using a fired formed unsized case and insert a bullet into the neck leaving it long. Then chamber it and allow the lands to seat the bullet further. Measure and repeat making sure there is no increased tension when closing the bolt and the bullet has not stuck into the lands. measure and adjust until you can get consistent OAL’s. try seating the bullet to this depth with dummy rounds and check the ease of chambering.

You might also try measuring from the muzzle to the bolt face when closed and locked, and compare that measurement to the bullet tip held against the lands. The difference gives you an OAL, but you also have to consider the difference in length on that specific bullet from the ogive to the tip and deduct that measurement for the maximum ogive length relative to your comparator bushing.

EDITOR: Yes there are differences between a Hornady Modified Case and your own fire-formed case. But in reality none of the concerns expressed above actually matter at all, so long as you get repeatable measurements. The reason is that you determine the best seating depth experimentally with your fire-formed cases. If you load .005 longer than your tool-determined base to ogive measurement or .020 shorter, for example, that’s all you need to know. The biggest problem with the tool is that some guys push too hard and actually jam the bullet into the lands. That can lead to inconsistent results. Practice with a gentle touch, then you’ll get a repeatable measurement. Then determine your load from there experimentally.