Reloading TIP — O-Rings Can Help Reduce Run-out When Sizing

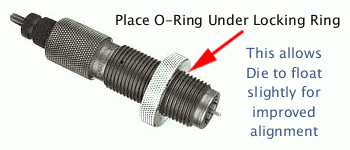

Here’s an inexpensive procedure that can help you load straighter ammo, with slightly better measured concentricity (i.e. less run-out) on the case necks and bullets. Simply use a Rubber O-Ring on the underside of the die locking ring. This allows the die to self-align itself (slightly) to the case that is being sized. Without the O-Ring, if the flat surface on the top of your press is not perfectly square with the thread axis, your die can end up slightly off-angle. This happens when the bottom of the locking ring butts up tight against the top of the press. The O-Ring allows the die to float slightly, and that may, in turn, reduce the amount of run-out induced during case sizing.

Top prone shooter GSArizona, who sadly passed last year, tried this trick and said it works: “Go to your local hardware store and get a #17 O-Ring (that’s the designation at Ace Hardware, don’t know if its universal). Slip the O-Ring on the die and re-adjust the lock ring so that the O-Ring is slightly compressed when the die is at the correct height. Size and measure a few more cases. You will probably see a slight improvement in neck concentricity as the die can now float a bit as the case enters and leaves it. This isn’t going to be a dramatic improvement, but it’s a positive one.”

We want to stress that adding O-Rings to sizing dies may help some reloaders, but we don’t offer this as a panacea. Try it — if using the O-Ring reduces measured runout that’s great. If it doesn’t, you’ve only spent a few pennies to experiment.

Lee Precision makes die lock rings with built-in O-Rings. Lee’s distinctive lock ring design allows the same kind of self-alignment, which is good. However, Lee lock rings don’t clamp in place on the die threads, so they can move when you insert or remove the dies — and that can throw off your die setting slightly. By using an O-Ring under a conventional die lock ring (that can be locked in place), you get the advantages of the Lee design, without the risk of the lock ring moving.

Similar Posts:

- Go with the “O” — O-Rings May Reduce Run-Out When Sizing

- O-Rings on Sizing Die Lock Rings Can Reduce Run-out

- Using O-Rings on Sizing Die Lock Rings Can Reduce Run-Out

- Try Using O-Rings with Sizing Dies for Reduced Neck Run-out

- TECH TIP: Use Rubber O-Rings with Sizing Dies for Less Run-Out

Tags: Concentricity, FL Sizing, Lee Precision, O-Ring, Reloading, Run-Out, Sizing Die

Great article. As a new reloader I wondered a lot about Lee’s lock rings and have heard complaints about Lee having the orings. I haven’t had any issue except as noted that the rings can move. Lee now had their ultimate lock ring which has a set screw so it doesn’t move and I have been using on my bullet seating dies.

For the O ring used with a conventional lock ring, or a Lee Lock ring to work as intended they cannot be set for an exact dies setting that will repeat after the die is removed. This is because properly used the O ring is only compressed enough to prevent the die from rotating in the press as seating depth adjustments are made. Unfortunately this does away with spin the die in until it stops die changing. For me, for FL dies this has not been an issue, because I have gotten, pretty fast at setting a die. In the case of the Lee lock ring, if you tighten things to the point where they are metal to metal with the top of the press, all of the advantage of the O ring is lost.