|

|

September 16th, 2007

Experienced handloaders consider many factors in determining loads for their rifles: type and amount of powder, primer “hotness”, brass strength in the web area, case neck tension, bullet weight, diameter and bearing surface, freebore length, seating depth, barrel land/groove configuration, and ambient temperature. Some folks even compensate for the altitude and humidity at the range. That pretty much covers it right? Wrong. You can get in BIG Trouble if you don’t account for barrel fouling as well.

Barrel fouling is not often discussed in reloading articles. Yet barrel fouling (both carbon and copper) can dramatically increase pressure inside a bore. It can do this in many ways. First a build-up of carbon ahead of the throat can increase pressures by constricting the bore. Likewise, heavy copper build-up can constrict the bore over a significant amount of its length. This means the bullet is being driven through what is, effectively, a smaller hole. As well, even a light layer of copper can increase friction. Added friction means more heat, and heat and pressure are directly related.

If you have a barrel that fouls heavily, and you need to shoot 20+ rounds with no opportunity to remove the fouling (say during a match), you should adjust your loads down so they are safe when the barrel is fouled. Don’t assume that a load which is safe in a “squeaky clean” bore will remain safe as your bore gets heavily fouled. This is especially true with non-lapped factory barrels with heavy “chatter marks” from machining. Look at this photo, provided by Forum member Clark. It shows the SAME load (identical bullet and powder charge) fired in the same barrel, at progressively heavier levels of copper fouling:

Pretty scary, right? Cartridge ‘C’, fired in a heavily coppered barrel, shows signs of catastrophic case failure, as well as damage to the primer. By comparison, cartridge ‘A’ merely shows some cratering, but the primer pocket edges are still rounded. ‘A’ is probably at the upper limit of a safe load. ‘C’ is at truly dangerous overpressure–with the same amount of powder in the case. The only difference was the amount of fouling in the barrel–particularly heavy copper.

September 15th, 2007

We are often asked “what’s the difference between the 6×47 Swiss Match, the 6XC, and the 6.5×47 Lapua necked down to 6mm?” All three cartridges have 30° shoulders and fit a .308-sized boltface. However, alone among the three, the 6mm-6.5×47 has a small primer pocket and small flash hole. The 6×47 Swiss Match (made by RUAG), and the 6XC (produced by Norma), have a large primer pocket and large flash hole, just like a .308 Winchester.

Forum member DesertLefty has provided a line-up photo, with 6mmBR and .260 Rem cases provided for comparison. As you can see, the three mid-sized cases (6x47SM, 6.5×47 Lapua, and 6XC) are very similar. The Swiss Match has the longest neck, while the 6XC enjoys the highest capacity. But performance is very similar among the three cartridges (with the 6.5×47 necked down to 6mm), and the same powders, particularly H4350 and IMR 4007SSC, work well in the 6×47 SM, the 6XC, and the 6.5×47 Lapua necked down to 6mm. The parent 6.5×47 Lapua case is rated at 63090 psi, while the new CIP rating for the 6XC 63844 psi (4400 BAR). Though the 6mm-6.5×47 has slightly less powder capacity than the 6XC, max velocities with 105-108gr bullets are quite similar. However, you should not substitute loads from the 6XC directly to the 6mm-6.5×47 or vice-versa. Because of the different case capacities and primer sizes, you should work up loads separately for each cartridge.

September 15th, 2007

Now through December 31, 2007, Weaver Optics is offering a “Upgrade” promotion on Weaver Grand Slam and Classic Extreme scopes. If you purchase one of these Weaver scopes, send in an old scope (any make or model, 1″ or 30mm), and fill out a form, Weaver will send you a $50 check. Or, you can still get a $25 rebate check if you mail in the redemption form with proof of purchase without sending in an old scope. Click HERE for more details and to obtain the mail-in Rebate Form.

September 14th, 2007

The 600-yard stage of the U.S. F-Class Nationals, at the NRA Whittington Center in Raton, NM was completed on the 13th. Many top F-Class shooters who have been featured on this site are competing, including recent champions John Brewer and Jeff Cochran. So far, the competition has been fierce. In F-Open, Cochran leads by a single point over Dean Morris. Today and tomorrow, competitors shoot at 1000 yards. Official results, as available, will be posted on the Bald Eagles Rifle Club website.

First Day F-Class Nationals Leaderboard

F-Open:

1. Jeff Cochran – 443-20X

2. Dean Morris – 442-16X3. John Brewer – 440-17X |

F/TR:

1. Mike Miller – 430-10X

2. Darrell Buell – 428-11X3. Mark Pharr – 427-12X |

Forum member Monte Milanuk offered this late-breaking report: “Conditions at 600 were squirrely at best. With a shortage of target pullers, we only had 18 targets, and 90+ shooters, so the order of the day was 5 relays. One relay might get an easy relay w/ either little wind, or at least readable wind, and the next might get one w/ complete 180° switches and huge pick-ups and let-offs. To some degree it averaged out over the course of three stages, but some people faired better than others. I’m pretty sure everybody got hosed at least once but some got it a couple times.

The rest of the Nationals is at 1000 yards, and if I’ve picked up anything over the last 6 days shooting here in Raton, it is that the 1K yard line is probably going to be bloody….”

September 14th, 2007

Keeping your loaded cases at a controlled temperature is vital for maintaining good ES and case life. At a late summer varmint match we observed pressure signs with cases that had been sitting in direct sunlight for about 15 minutes. As we were running a “moderate” RL15 load, the pressure indications were surprising. Testing over a chronograph, cases that had been sitting in direct sunlight showed velocities up to 70 fps higher than those that had been kept in the shade. Using QuickLoad’s temperature function, we calculated from the rise in velocities that case pressures had increased by over 4,000 psi–just from 15-20 minutes in direct sunlight!

We will now keep a temp strip in our ammo boxes at all times. Neconos.com offers Bar-L Benchrest temp strips that visually display heat readings from 86 to 140 degrees (our cases got warm to the touch so they were probably about 110-120° F). Think of these strips as compact, unbreakable thermometers. With adhesive backing, they can also be used to monitor barrel heating. Put a strip on the side of the barrel and the barrel’s temp will be indicated by a stripe that changes from black to green. There is also a “general purpose” strip that reads to 196 degrees (bottom row). The Benchrest strip is in the middle.

September 14th, 2007

The Third Annual Shilen Swap Meet will be held on October 27, 8am to 3pm in Shilen’s parking lot at 205 Metro Park Blvd., Ennis, Texas. All buyers and sellers are invited–and you’re welcome to just come and mingle or take a tour of the factory. Anyone can set up a table or just drop your tailgate. There are no fees and the Swap Meet will go forward rain or shine (Shilen rents a tent). Shilen will also provide complementary chili, frito pie and soft drinks. Shilen’s organizers noted: “Please call (972) 875-5318 if you plan on attending so we can have a rough head count. If you want to put up a table please call, fax or email us and let us know. We will add you to the list of vendors”

As an added incentive, Shilen Rifles will offer discounted “Swap Meet Barrels”. Shilen’s Mike Hull reports: “Last year was the first year we offered our ‘Swap Meet Barrels’ and they will be BACK this YEAR by popular demand. These are barrels that we have from customers who ordered a certain contour, or caliber and then changed their mind and wanted something else. In the name of customer service we let the customer change their order and then placed the barrel back in stock. Those barrels that are still left at Swap Meet time are offered at discounted prices! All warranties still apply; these are NOT of lower quality or factory seconds.”

September 13th, 2007

The 4th Annual U.S. F-Class Championships runs Sept. 13-15 at the NRA Whittington Center, Raton, New Mexico. If you are near the area, head over to Raton to witness the action–many of the nation’s best long-range shooters will be competing. The F-Class Championship follows on the heels of the Spirit of America (SOA) match, hosted at the Whittington Center earlier this week. This is the first time the SOA and the F-Class Nationals have been held back to back.

Spirit of America F-Class results have been tallied. Team Savage shot consistently to win the Team Competition. Posting in Long-Range.com, Warren Dean reported: “Darrell Buell absolutely dominated the SOA/Fullbore Nats in the F-T/R division, winning 2 of the 4 matches and taking a 2nd in another. Conditions were a pretty squirrely at times and far from optimal, but Darrell took us all to school on reading the wind.” We were also pleased to see Forum Members John Dink and Monte Milanuk in the F-TR top 3. In F-Open, U.S. F-Class Teammates Jim Murphy, Larry Bartholome, and John Brewer finished first through third respectively. We can expect more from all these shooters in the next few days.

Spirit of America F-Class Results

F-Open

1. Jim Murphy

2. Larry Bartholome

3. John Brewer |

F-TR

1. Darrell Buell

2. John Dink

3. Monte Milanuk |

September 13th, 2007

As promised, here are specifics on the new 95 grain Sierra MatchKing bullet. As you can see below, it looks very similar to the Sierra 107 MatchKing, but it’s just a bit shorter, with a bit more curve in the top quarter. Our samples measured 0.2433 at the pressure ring — same as the current Sierra 107 MKs. Jason Baney provides this info:

95 SMK OAL: 1.182″ | 107 SMK OAL: 1.216″ | 105 Berger OAL: 1.235″

Shown below is Jason’s group from long-range testing. Jason tells us: “I had 8 shots group 2.75″ high x 3.5″ wide, with nine shots in just 4.2″–that’s excellent. One shot went high, opening it up to 6.9″. Keep in mind a 4.2″ is considered pretty spectacular at Williamsport. And a 6.9″ is a very competitive group that will win many relays. I shot this group in decent, but nowhere near perfect, conditions at 1025 yards. These new 95s definitely have some potential at 1000. . . and even more at 600 yards.”

September 13th, 2007

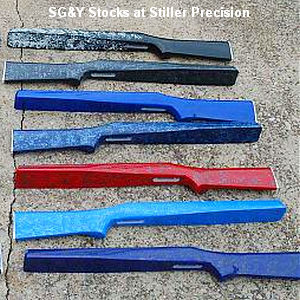

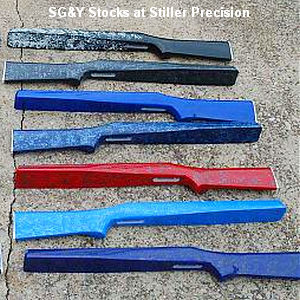

When Speedy closed up shop at SG&Y in Texas and headed off to Colorado to teach gunsmithing, he had quite a few of the superbly-crafted BRX stocks in inventory. Built by Robertson Composites in Canada, these BRX models are truly some of the nicest fiberglass stocks you can buy. The geometry is correct, sidewalls are straight and the flats are uniform without center seams. The external finish is top-notch, a high-gloss gelcoat without flaws and voids.

CLICK for Stock Info and BIG PHOTOS

Jerry Stiller acquired Speedy’s inventory of Robertson BRX stocks and they are now for sale. Price is $375 partially inletted with fitted buttplate, plus shipping. Jerry has a dozen or more, in various colors, most with a marble two-tone design. If you want one, don’t delay–these are selling fast. Call (972) 429-5000. You can see details in the photos below, originally taken by Speedy. (These colors may no longer be available.)

September 12th, 2007

EXCLUSIVE AccurateShooter.com Report

Sierra Bullets has a new 95gr, 6mm boat-tail MatchKing bullet. It is optimized for 1:10 (or faster) twist rate barrels. Jason Baney has tested prototypes of the new Sierra 95 MK and it has shot very well at 1000 yards. This should be an excellent bullet for both match shooters AND varminters. It can be driven much faster than a 105-107 grain bullet from a 6BR–3050 fps is doable with a 27″ or longer barrel. This bullet should be a screamer in a 6XC, 6-6.5×47, or .243 Win. The Ballistic Coefficient (BC) hasn’t been calculated yet, but Sierra’s engineers believe it will be “around 0.500″. The bullet diameter is spec’d at .2432″-.2434″ at the junction of the shank and boat-tail (pressure ring).

Sierra is drawing jackets for the new 95gr SMK right now, and it anticipates the first lots will be delivered to retailers “after Thanksgiving”, if not sooner.

Sierra had asked us to keep this bullet under wraps until a final decision was made to put the new projectile in production. According to Rich Macholz of Sierra, “We’ve been very happy with our test results and we know there’s a need for a bullet in this weight range. We see the 95 as ideal for guys with factory .243s and the like who want a super-accurate bullet that works in a 10-twist barrel. It should also work great at 300 meters with a 6BR or 6XC. I’ve shot the 95s in my own 243 and won a match with it. As with all MatchKings, the new 95 has a strong jacket and this bullet can be pushed to 3400 fps and beyond without problems. If you want a bullet for a .243 Ackley or 6-284, this 95 SMK can handle the velocity. It should be a great choice for the Varmint Jamboree and similar competitions.”

Stay tuned to the Daily Bulletin. Jason has a supply of the new 95-grainers and he will supply close-up photos and further specifications very soon. For more info on the new 95 Sierra MK, call 1-800-223-8799 to speak with a Sierra Bulletsmith.

|